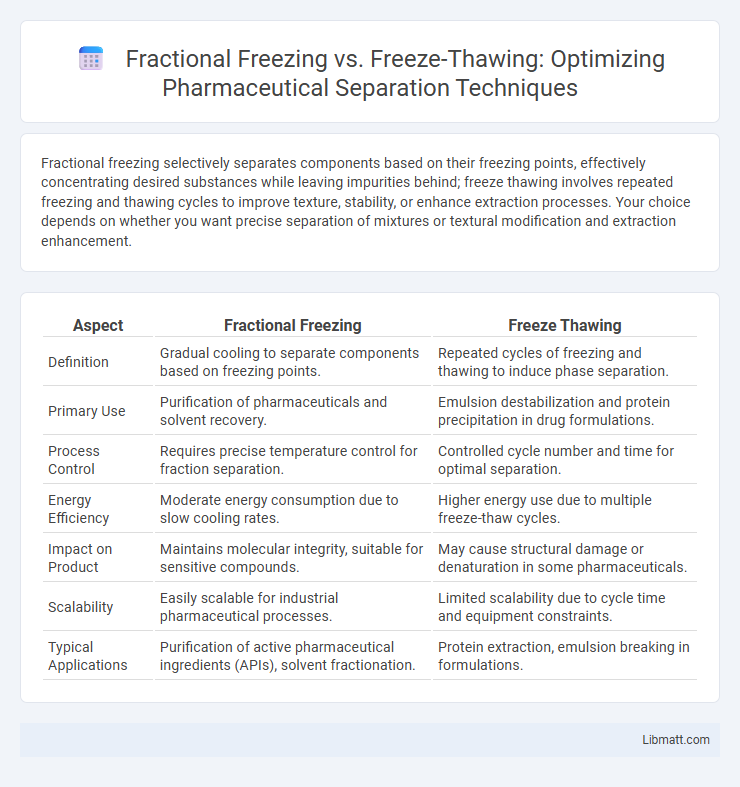

Fractional freezing selectively separates components based on their freezing points, effectively concentrating desired substances while leaving impurities behind; freeze thawing involves repeated freezing and thawing cycles to improve texture, stability, or enhance extraction processes. Your choice depends on whether you want precise separation of mixtures or textural modification and extraction enhancement.

Table of Comparison

| Aspect | Fractional Freezing | Freeze Thawing |

|---|---|---|

| Definition | Gradual cooling to separate components based on freezing points. | Repeated cycles of freezing and thawing to induce phase separation. |

| Primary Use | Purification of pharmaceuticals and solvent recovery. | Emulsion destabilization and protein precipitation in drug formulations. |

| Process Control | Requires precise temperature control for fraction separation. | Controlled cycle number and time for optimal separation. |

| Energy Efficiency | Moderate energy consumption due to slow cooling rates. | Higher energy use due to multiple freeze-thaw cycles. |

| Impact on Product | Maintains molecular integrity, suitable for sensitive compounds. | May cause structural damage or denaturation in some pharmaceuticals. |

| Scalability | Easily scalable for industrial pharmaceutical processes. | Limited scalability due to cycle time and equipment constraints. |

| Typical Applications | Purification of active pharmaceutical ingredients (APIs), solvent fractionation. | Protein extraction, emulsion breaking in formulations. |

Introduction to Fractional Freezing and Freeze Thawing

Fractional freezing is a separation technique that exploits differences in freezing points to isolate specific components from a mixture by controlled crystallization. Freeze thawing involves repeatedly freezing and thawing a sample to disrupt cellular structures or facilitate phase separation. Both methods are valuable in fields like food processing, environmental science, and pharmaceuticals for purification and analysis purposes.

Principles of Fractional Freezing

Fractional freezing separates components based on their distinct freezing points, causing purer solids to crystallize while impurities remain in the liquid phase. This process is widely used for desalination, alcohol purification, and concentrating fruit juices by gradually lowering the temperature to selectively freeze and remove unwanted substances. Your understanding of fractional freezing's principle enables better application in industries requiring precise separation of mixtures through controlled crystallization.

Understanding Freeze Thawing Techniques

Freeze thawing techniques involve repeatedly freezing a liquid and then thawing it to separate components based on their different melting points or solubilities. This method is commonly used to purify water by forming ice crystals that exclude impurities, effectively concentrating solutes in the remaining liquid phase. Understanding the precise temperature cycles and rates of freezing and thawing is crucial for optimizing separation efficiency and ensuring the integrity of sensitive substances in applications such as wastewater treatment and food processing.

Key Differences Between Fractional Freezing and Freeze Thawing

Fractional freezing separates components by selectively freezing and removing ice crystals, concentrating the remaining liquid, while freeze-thawing involves repeated cycles of freezing and thawing causing physical and chemical changes in the material. Fractional freezing is primarily used for purification and concentration, whereas freeze-thawing impacts texture, structure, and can lead to material degradation or phase separation. Key differences lie in their purpose--fractional freezing targets phase separation for purification, and freeze-thawing induces structural modifications through temperature cycling.

Applications in Industry and Research

Fractional freezing is widely used in the food industry to concentrate flavors and remove impurities, enhancing product quality in beverages and dairy processing. Freeze thawing is essential in material science for studying the effects of ice crystal formation on soil and concrete durability, aiding in infrastructure development. Both techniques support pharmaceutical research by improving drug formulation stability and facilitating cryopreservation of biological samples.

Advantages of Fractional Freezing

Fractional freezing allows selective separation of components based on their freezing points, leading to higher purity products compared to freeze thawing. This method minimizes structural damage and preserves the texture of sensitive materials, which is critical in food processing and pharmaceutical applications. Energy efficiency and reduced processing time are also key advantages, making fractional freezing a preferred technique for industrial-scale separation.

Benefits and Limitations of Freeze Thawing

Freeze thawing offers benefits such as effective separation of impurities and concentrated solutions by exploiting differences in freezing points. Its limitations include potential structural damage to delicate materials and the need for controlled temperature cycles to prevent inconsistent results. Understanding these factors helps you optimize the process for applications like water purification or food preservation.

Efficiency and Purity Outcomes Compared

Fractional freezing offers higher efficiency by selectively crystallizing pure solvent, resulting in significantly enhanced purity levels compared to freeze thawing. Freeze thawing often leads to incomplete phase separation, which reduces overall purity and recovery rates. Efficiency disparities arise as fractional freezing enables multiple iterative cycles, optimizing solute concentration and minimizing impurities.

Environmental and Economic Impacts

Fractional freezing significantly reduces water usage and energy consumption compared to traditional freeze thawing methods, making it a more environmentally sustainable option in industrial applications. Economically, fractional freezing lowers operational costs by enhancing process efficiency and minimizing waste generation, resulting in higher profitability and reduced disposal expenses. The decreased environmental footprint and cost savings position fractional freezing as a preferable technique in sectors such as food processing and wastewater treatment.

Choosing the Right Method for Your Needs

Fractional freezing precisely separates components based on their distinct freezing points, making it ideal for purifying substances like alcohol or removing impurities. Freeze thawing cycles are better suited for testing material durability or inducing structural changes through repeated freezing and thawing. Your choice depends on whether you need targeted separation or evaluation of material resilience under temperature stress.

Fractional Freezing vs Freeze Thawing Infographic

libmatt.com

libmatt.com