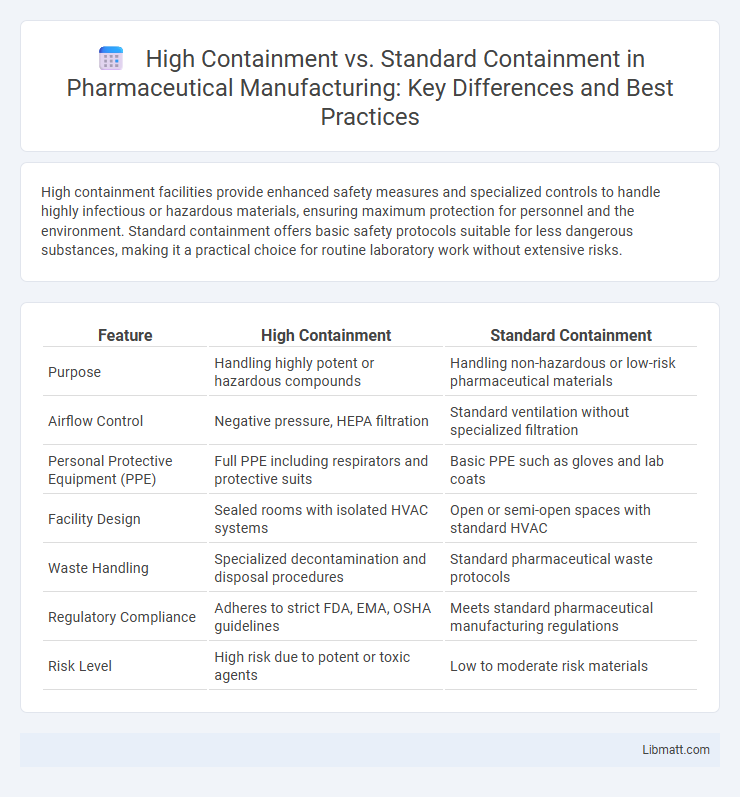

High containment facilities provide enhanced safety measures and specialized controls to handle highly infectious or hazardous materials, ensuring maximum protection for personnel and the environment. Standard containment offers basic safety protocols suitable for less dangerous substances, making it a practical choice for routine laboratory work without extensive risks.

Table of Comparison

| Feature | High Containment | Standard Containment |

|---|---|---|

| Purpose | Handling highly potent or hazardous compounds | Handling non-hazardous or low-risk pharmaceutical materials |

| Airflow Control | Negative pressure, HEPA filtration | Standard ventilation without specialized filtration |

| Personal Protective Equipment (PPE) | Full PPE including respirators and protective suits | Basic PPE such as gloves and lab coats |

| Facility Design | Sealed rooms with isolated HVAC systems | Open or semi-open spaces with standard HVAC |

| Waste Handling | Specialized decontamination and disposal procedures | Standard pharmaceutical waste protocols |

| Regulatory Compliance | Adheres to strict FDA, EMA, OSHA guidelines | Meets standard pharmaceutical manufacturing regulations |

| Risk Level | High risk due to potent or toxic agents | Low to moderate risk materials |

Introduction to Biological Containment Levels

Biological containment levels are categorized into standard containment and high containment based on the risk posed by the microorganisms handled. Standard containment, typically BSL-1 or BSL-2, is designed for agents with minimal to moderate risk, focusing on basic safety protocols and equipment. High containment, such as BSL-3 and BSL-4, involves stringent controls, specialized facilities, and advanced protective measures to manage dangerous pathogens that can cause serious or lethal diseases.

Defining High Containment Facilities

High containment facilities are specialized laboratories designed to safely handle highly infectious and hazardous pathogens, often classified as Biosafety Level 3 (BSL-3) or Biosafety Level 4 (BSL-4). These facilities incorporate advanced engineering controls such as airtight seals, HEPA filtration, and strict access protocols to prevent the release of dangerous biological agents. Your research requiring maximum biological safety and risk mitigation benefits significantly from the enhanced protocols and infrastructure of high containment versus standard containment labs.

Overview of Standard Containment Practices

Standard containment practices involve maintaining controlled environments designed to prevent the release of hazardous biological agents through physical barriers, air filtration, and strict access protocols. Commonly applied in Biosafety Level 2 (BSL-2) laboratories, these practices include the use of personal protective equipment (PPE), biosafety cabinets, and decontamination procedures to minimize exposure risks. Emphasis on routine monitoring, sterilization of laboratory materials, and effective waste management ensures compliance with regulatory standards and safeguards personnel and the environment.

Key Differences Between High and Standard Containment

High containment facilities feature advanced engineering controls such as airtight barriers, negative air pressure, and HEPA filtration to prevent the escape of hazardous biological agents, whereas standard containment relies on standard biosafety cabinets and basic laboratory practices. High containment labs operate under stringent regulatory requirements and biosafety levels 3 or 4, designed for handling highly infectious or dangerous pathogens, contrasting with standard containment, which suits lower-risk agents at biosafety levels 1 or 2. The structural design, safety protocols, and personnel training in high containment environments are significantly more rigorous to ensure maximum protection for workers and the environment.

Biosafety Level Classifications Explained

High containment facilities correspond to Biosafety Level 3 (BSL-3) and Level 4 (BSL-4), designed for work involving pathogens that pose serious or lethal risks to humans, requiring specialized ventilation, sealed environments, and stringent access controls. Standard containment typically refers to Biosafety Level 1 (BSL-1) and Level 2 (BSL-2), handling agents not known to cause disease or those with moderate risk, utilizing basic laboratory practices and safety equipment. Understanding these biosafety level classifications helps you implement appropriate protective measures and ensures compliance with safety regulations in laboratory environments.

Infrastructure Requirements for High Containment

High containment facilities demand advanced infrastructure including airtight, reinforced barriers, specialized ventilation systems with HEPA filtration, and strict access controls to prevent pathogen escape. Unlike standard containment labs, these environments require continuous monitoring of pressure differentials and decontamination protocols to ensure biosafety. Your laboratory design must integrate durable materials resistant to chemical and biological agents, supporting high-level biosecurity standards.

Operational Protocols: High vs Standard Containment

High containment operational protocols require rigorous entry and exit procedures, including multiple decontamination steps, use of specialized personal protective equipment (PPE), and strict air filtration systems to prevent pathogen release. Standard containment protocols involve basic safety measures such as standard PPE, surface disinfection, and controlled access without the need for advanced engineering controls. Your adherence to these protocols ensures safety and compliance with biosafety level requirements specific to the pathogen's risk group.

Risk Assessment and Management Strategies

High containment facilities utilize rigorous risk assessment protocols tailored to handle highly infectious agents, incorporating advanced engineering controls and strict access restrictions to prevent pathogen escape. Standard containment focuses on managing moderate risks through established biosafety practices and routine monitoring, balancing safety with operational efficiency. Your choice depends on pathogen hazard levels and the corresponding need for specialized management strategies to mitigate potential exposure and contamination.

Applications and Use Cases in Research and Industry

High containment laboratories (BSL-3 and BSL-4) are essential for researching highly infectious pathogens like Ebola and SARS-CoV-2, enabling safe study and development of vaccines and therapeutics. Standard containment facilities (BSL-1 and BSL-2) support routine research on less hazardous microorganisms, including molecular biology, vaccine production, and pharmaceutical development. Industries such as biotechnology, pharmaceuticals, and public health rely on the appropriate containment levels to ensure safety while advancing infectious disease research and biosecurity.

Regulatory Compliance and Future Trends

High containment laboratories adhere to stricter regulatory compliance frameworks such as BSL-3 and BSL-4 standards enforced by agencies like the CDC and WHO, ensuring maximum safety for research involving highly pathogenic agents. Standard containment facilities comply with lower-tier regulations like BSL-1 and BSL-2, suitable for less hazardous biological materials with simpler operational protocols. Future trends emphasize integrating advanced digital monitoring, automated decontamination systems, and adaptive regulatory guidelines to enhance safety, efficiency, and responsiveness in both high and standard containment environments.

High Containment vs Standard Containment Infographic

libmatt.com

libmatt.com