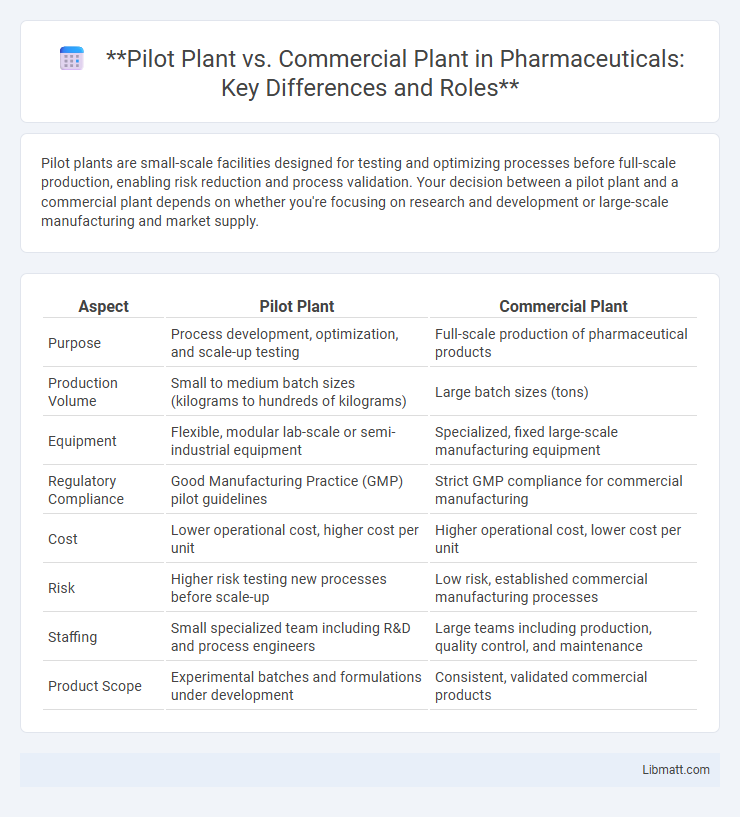

Pilot plants are small-scale facilities designed for testing and optimizing processes before full-scale production, enabling risk reduction and process validation. Your decision between a pilot plant and a commercial plant depends on whether you're focusing on research and development or large-scale manufacturing and market supply.

Table of Comparison

| Aspect | Pilot Plant | Commercial Plant |

|---|---|---|

| Purpose | Process development, optimization, and scale-up testing | Full-scale production of pharmaceutical products |

| Production Volume | Small to medium batch sizes (kilograms to hundreds of kilograms) | Large batch sizes (tons) |

| Equipment | Flexible, modular lab-scale or semi-industrial equipment | Specialized, fixed large-scale manufacturing equipment |

| Regulatory Compliance | Good Manufacturing Practice (GMP) pilot guidelines | Strict GMP compliance for commercial manufacturing |

| Cost | Lower operational cost, higher cost per unit | Higher operational cost, lower cost per unit |

| Risk | Higher risk testing new processes before scale-up | Low risk, established commercial manufacturing processes |

| Staffing | Small specialized team including R&D and process engineers | Large teams including production, quality control, and maintenance |

| Product Scope | Experimental batches and formulations under development | Consistent, validated commercial products |

Introduction to Pilot Plants and Commercial Plants

Pilot plants serve as small-scale industrial systems used for testing and optimizing processes before full-scale production, enabling companies to identify potential issues and improve efficiency. Commercial plants operate at full capacity, producing large quantities of products intended for market distribution based on proven processes validated in pilot plants. Your understanding of the distinction between pilot and commercial plants is crucial for successful process development and scaling.

Key Differences Between Pilot and Commercial Plants

Pilot plants operate on a smaller scale to test processes and gather data, allowing adjustments before full-scale production, while commercial plants focus on large-scale manufacturing to meet market demand efficiently. The key differences include scale, cost, operational complexity, and purpose: pilot plants emphasize experimentation and process validation, whereas commercial plants prioritize consistent output and profitability. Your choice between the two depends on the stage of development and production goals, ensuring effective resource allocation and risk management.

Purpose and Objectives of a Pilot Plant

A pilot plant is designed to test and optimize processes on a smaller scale before full-scale commercial production, allowing for troubleshooting, process validation, and refinement of operating parameters. Its primary objective is to generate reliable data on process performance, scalability, and product quality, minimizing risks and uncertainties. Commercial plants, in contrast, focus on large-scale production, efficiency, and meeting market demand with established and validated processes.

Scale and Capacity Comparison

Pilot plants typically operate at a smaller scale with limited capacity, designed to test processes and produce quantities ranging from a few kilograms to several tons per year. Commercial plants function at a much larger scale, optimized for mass production with capacities often reaching thousands of tons annually. This scale difference impacts equipment size, process control complexity, and overall operational costs.

Process Design and Optimization in Pilot Plants

Pilot plants play a crucial role in process design and optimization by allowing engineers to test and refine production methods on a smaller scale before full-scale commercial implementation. These plants enable detailed analysis of process parameters, material flow, and equipment performance, ensuring scalability and cost-effectiveness. Data collected from pilot plant operations directly inform adjustments that improve efficiency and product quality in commercial plants.

Cost Implications: Pilot vs Commercial Operations

Pilot plants incur lower upfront costs due to smaller scale equipment and limited production capacity, making them ideal for process development and troubleshooting. Commercial plants require significant capital investment for full-scale operations, encompassing large-scale machinery, infrastructure, and operational expenses. Your decision should weigh the cost-effectiveness of pilot testing against the higher financial risks and returns of commercial deployment.

Technology Validation and Risk Mitigation

Pilot plants play a crucial role in technology validation by providing a controlled environment to test processes on a smaller scale, identifying potential issues before full-scale production. These facilities help mitigate risks related to scalability, cost, and performance, ensuring that the technology performs consistently under real-world conditions. Your investment in a pilot plant reduces the likelihood of costly failures in the commercial plant phase, safeguarding operational success.

Transitioning from Pilot to Commercial Scale

Transitioning from a pilot plant to a commercial plant involves scaling up processes to meet production demands while maintaining product quality and process efficiency. You must optimize equipment design, ensure regulatory compliance, and validate operational parameters to support larger volumes and continuous operation. Successful scale-up depends on thorough data analysis from pilot trials and collaboration between engineering, production, and quality teams.

Regulatory and Safety Considerations

Pilot plants operate under stringent regulatory oversight tailored to small-scale testing, emphasizing flexible safety protocols to manage experimental risks and modifications. Commercial plants must comply with comprehensive industry regulations, including environmental, health, and occupational safety standards, ensuring consistent large-scale production with minimized hazards. Both require detailed documentation and risk assessments, but commercial plants prioritize long-term regulatory compliance and robust safety management systems.

Case Studies: Successful Scale-Up from Pilot to Commercial Plant

Case studies of successful scale-up from pilot to commercial plant demonstrate critical factors such as accurate process modeling, thorough risk assessment, and effective technology transfer protocols. Companies like DuPont and Tesla have achieved seamless transitions by optimizing pilot data to anticipate scale-related challenges, ensuring consistent product quality and operational efficiency. These examples highlight the importance of robust pilot plant design and strategic project management in minimizing costly delays during commercial plant commissioning.

Pilot plant vs Commercial plant Infographic

libmatt.com

libmatt.com