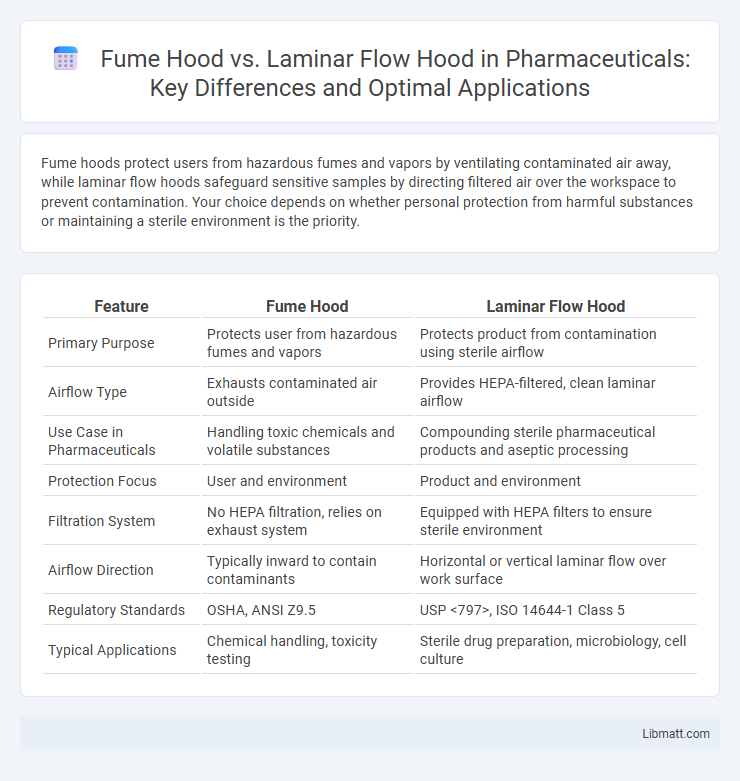

Fume hoods protect users from hazardous fumes and vapors by ventilating contaminated air away, while laminar flow hoods safeguard sensitive samples by directing filtered air over the workspace to prevent contamination. Your choice depends on whether personal protection from harmful substances or maintaining a sterile environment is the priority.

Table of Comparison

| Feature | Fume Hood | Laminar Flow Hood |

|---|---|---|

| Primary Purpose | Protects user from hazardous fumes and vapors | Protects product from contamination using sterile airflow |

| Airflow Type | Exhausts contaminated air outside | Provides HEPA-filtered, clean laminar airflow |

| Use Case in Pharmaceuticals | Handling toxic chemicals and volatile substances | Compounding sterile pharmaceutical products and aseptic processing |

| Protection Focus | User and environment | Product and environment |

| Filtration System | No HEPA filtration, relies on exhaust system | Equipped with HEPA filters to ensure sterile environment |

| Airflow Direction | Typically inward to contain contaminants | Horizontal or vertical laminar flow over work surface |

| Regulatory Standards | OSHA, ANSI Z9.5 | USP <797>, ISO 14644-1 Class 5 |

| Typical Applications | Chemical handling, toxicity testing | Sterile drug preparation, microbiology, cell culture |

Introduction to Fume Hoods and Laminar Flow Hoods

Fume hoods are ventilated enclosures designed to protect users from hazardous fumes, vapors, and dust by exhausting contaminated air outside the laboratory environment. Laminar flow hoods provide a sterile workspace by directing filtered air through HEPA filters in a unidirectional flow, typically used for sensitive biological or electronic tasks. Choosing the right hood depends on your need for either personal safety from toxic substances or contamination-free environments.

Purpose and Applications of Fume Hoods

Fume hoods are designed to protect users from hazardous fumes, vapors, and particulate matter generated during chemical experiments and industrial processes by ventilating harmful substances away from the breathing zone. They are commonly used in laboratories handling volatile chemicals, toxic gases, and reactive substances to ensure a safe working environment. Your choice of a fume hood is critical for applications involving dangerous chemical reactions, solvent handling, and any process generating airborne contaminants.

Purpose and Applications of Laminar Flow Hoods

Laminar flow hoods are designed to provide a sterile working environment by directing filtered air across the workspace to protect samples from contamination, commonly used in microbiology, pharmaceuticals, and electronics assembly. Their purpose is to maintain a particle-free environment, ensuring that your sensitive experiments or processes are not compromised by airborne contaminants. Unlike fume hoods, which protect the user by removing hazardous fumes, laminar flow hoods focus primarily on safeguarding the product from contamination.

Key Differences Between Fume Hoods and Laminar Flow Hoods

Fume hoods protect users by venting hazardous fumes and vapors outside the lab, while laminar flow hoods maintain a sterile environment by circulating HEPA-filtered airflow to protect samples. Your choice depends on the need for chemical containment versus contamination control, as fume hoods focus on user safety and laminar flow hoods prioritize product safety. Key differences include airflow direction, filtration methods, and the primary purpose of either removing contaminants from the user's environment or preventing particulate contamination of sensitive materials.

Airflow Mechanisms and Designs Explained

Fume hoods operate by drawing contaminated air away from the user through exhaust ventilation, typically using downward or sash-controlled airflow to capture hazardous fumes and chemicals. Laminar flow hoods provide a continuous, unidirectional stream of filtered air, either vertical or horizontal, to protect the work surface from particulate contamination without exhausting air outside. Understanding the distinct airflow mechanisms can help you choose the appropriate hood for either user safety in chemical handling or contamination control in sterile environments.

Safety Features and Protective Capabilities

Fume hoods are designed to protect users from hazardous chemical fumes by exhausting contaminated air outside the laboratory, utilizing airflow barriers and sash windows to minimize exposure. Laminar flow hoods provide a sterile environment by directing HEPA-filtered air across the work surface, protecting samples from contamination but offering limited user protection from toxic fumes or vapors. Choosing between these devices depends on whether the priority is safeguarding personnel from hazardous substances (fume hood) or maintaining product sterility (laminar flow hood).

Common Laboratory Uses for Each Hood Type

Fume hoods are primarily used for handling hazardous chemical vapors, gases, and particulates to protect laboratory personnel and maintain a safe working environment. Laminar flow hoods provide a sterile workspace by directing HEPA-filtered air to prevent contamination, making them ideal for microbiology, tissue culture, and pharmaceutical compounding. Your choice depends on whether the focus is on pollutant containment with a fume hood or contamination control with a laminar flow hood.

Maintenance and Operational Guidelines

Fume hoods require regular inspection of airflow velocity and filter integrity to ensure hazardous fumes are effectively removed, while laminar flow hoods demand frequent filter replacement and surface sterilization to maintain sterile airflow for contamination-sensitive work. Proper maintenance of fume hoods involves checking sash positions and exhaust systems for functionality, whereas laminar flow hoods need consistent monitoring of HEPA filter performance and workspace cleanliness. Operational guidelines emphasize training personnel on correct usage, including avoiding obstruction of airflow in fume hoods and minimizing turbulence in laminar flow hoods to preserve sterile conditions.

Cost Considerations and Budgeting

Fume hoods generally have higher upfront and operational costs due to complex ventilation and exhaust systems, making them a significant investment for laboratories handling hazardous chemicals. Laminar flow hoods, designed for contamination control without exhaust requirements, tend to be more cost-effective and require less maintenance, fitting smaller budgets focused on sterile environments. Evaluating your lab's specific safety and cleanliness needs helps determine the best balance between initial cost, ongoing expenses, and regulatory compliance for your budgeting.

Choosing the Right Hood for Your Laboratory Needs

Selecting the right hood for your laboratory depends on the specific protection requirements: Fume hoods are designed to remove hazardous fumes and vapors, providing safety for personnel working with toxic chemicals, while laminar flow hoods offer a sterile environment by directing filtered air across the workspace to protect samples from contamination. Understanding whether your primary need is chemical hazard containment or contamination control will guide the choice between these two hoods. Your laboratory's safety protocols and workflow demands should align with the hood's function to optimize both protection and efficiency.

Fume Hood vs Laminar Flow Hood Infographic

libmatt.com

libmatt.com