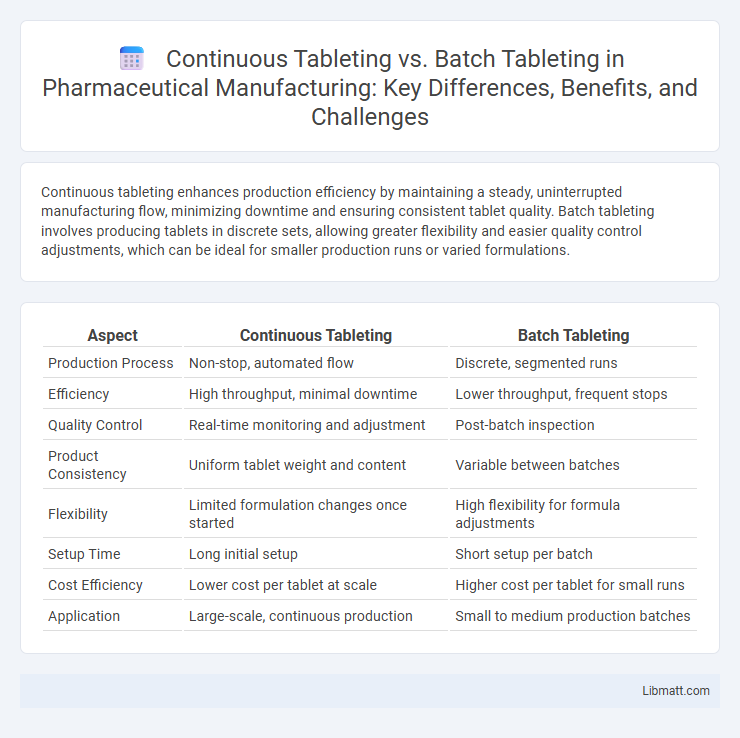

Continuous tableting enhances production efficiency by maintaining a steady, uninterrupted manufacturing flow, minimizing downtime and ensuring consistent tablet quality. Batch tableting involves producing tablets in discrete sets, allowing greater flexibility and easier quality control adjustments, which can be ideal for smaller production runs or varied formulations.

Table of Comparison

| Aspect | Continuous Tableting | Batch Tableting |

|---|---|---|

| Production Process | Non-stop, automated flow | Discrete, segmented runs |

| Efficiency | High throughput, minimal downtime | Lower throughput, frequent stops |

| Quality Control | Real-time monitoring and adjustment | Post-batch inspection |

| Product Consistency | Uniform tablet weight and content | Variable between batches |

| Flexibility | Limited formulation changes once started | High flexibility for formula adjustments |

| Setup Time | Long initial setup | Short setup per batch |

| Cost Efficiency | Lower cost per tablet at scale | Higher cost per tablet for small runs |

| Application | Large-scale, continuous production | Small to medium production batches |

Introduction to Tableting Processes

Continuous tableting processes offer real-time tablet production with consistent quality and increased efficiency by integrating all manufacturing steps into a seamless workflow. Batch tableting involves producing tablets in discrete, separate batches, allowing for flexibility in formulation changes and easier quality control but often results in higher downtime and lower overall productivity. Understanding the differences between continuous and batch tableting is crucial for optimizing pharmaceutical manufacturing based on production scale, product complexity, and regulatory requirements.

Defining Continuous Tableting

Continuous tableting is a pharmaceutical manufacturing process where tablets are produced non-stop, integrating powder feeding, granulation, drying, and compression in a seamless workflow. This method enhances efficiency by reducing cycle times and minimizing material waste compared to traditional batch tableting. Your production line benefits from consistent tablet quality and real-time process monitoring inherent in continuous tableting technology.

Understanding Batch Tableting

Batch tableting processes involve producing a specified quantity of tablets in discrete, separate production runs, allowing for precise control over formulation and quality parameters for each batch. This method relies on well-established equipment such as tablet presses and granulators, with quality checks performed at defined intervals to ensure consistency. Batch tableting is ideal for small to medium production volumes, enabling flexibility in formulation adjustments and compliance with regulatory standards.

Key Differences Between Continuous and Batch Tableting

Continuous tableting operates with a steady, uninterrupted flow of materials, ensuring consistent tablet quality and higher production efficiency, whereas batch tableting processes materials in discrete, separate batches, allowing for easier customization and flexibility. Continuous tableting reduces downtime and is ideal for large-scale, high-demand pharmaceutical production, while batch tableting suits smaller-scale production and specialized formulations. The key differences lie in process flow, scalability, and adaptability to changing production needs.

Equipment and Technology Requirements

Continuous tableting requires advanced equipment with integrated real-time monitoring systems and automated controls to ensure consistent tablet quality throughout the process. Batch tableting relies on traditional, standalone machines that process fixed quantities sequentially, often necessitating manual intervention and quality checks between batches. Your choice between these methods will impact equipment investment, operational complexity, and scalability demands.

Efficiency and Throughput Comparison

Continuous tableting offers significantly higher efficiency and throughput compared to batch tableting by enabling nonstop production and reducing downtime between runs. This method leverages real-time process monitoring and control, resulting in consistent tablet quality and faster response to production issues. Your manufacturing process can benefit from increased productivity and lower operational costs by adopting continuous tableting technology.

Quality Control and Consistency Factors

Continuous tableting enhances quality control by enabling real-time monitoring and immediate adjustments, reducing variability and ensuring consistent tablet weight, hardness, and content uniformity. Batch tableting relies on periodic sampling, which may miss deviations during production, potentially compromising product consistency and increasing waste. Your manufacturing process benefits from continuous tableting's ability to maintain tighter quality specifications and improve overall production efficiency.

Regulatory Considerations in Tableting

Regulatory considerations in continuous tableting emphasize real-time monitoring and process analytical technology (PAT) integration to ensure consistent product quality, reducing batch variability risks. Batch tableting requires strict adherence to predefined batch records and sampling protocols for quality control, which can lead to longer release times. Continuous manufacturing aligns with FDA and EMA guidelines promoting Quality by Design (QbD) and continuous verification, facilitating faster regulatory approvals and enhanced process control.

Cost Implications and Resource Optimization

Continuous tableting significantly reduces operational costs by minimizing downtime and enhancing production efficiency through real-time quality monitoring and automation. Batch tableting incurs higher labor and maintenance expenses due to frequent changeovers and cleaning cycles between lots. Resource optimization in continuous processes leads to better material utilization and lower energy consumption, whereas batch processing often results in increased waste and longer production times.

Future Trends in Pharmaceutical Tableting

Continuous tableting is revolutionizing pharmaceutical manufacturing by enabling real-time quality control and higher production efficiency compared to traditional batch tableting. Industry trends highlight a shift towards continuous processes driven by advancements in process analytical technology (PAT) and automation to ensure consistent drug quality and reduce waste. Your facility can benefit from adopting continuous tableting systems to meet regulatory expectations and optimize large-scale production in the evolving pharmaceutical landscape.

Continuous Tableting vs Batch Tableting Infographic

libmatt.com

libmatt.com