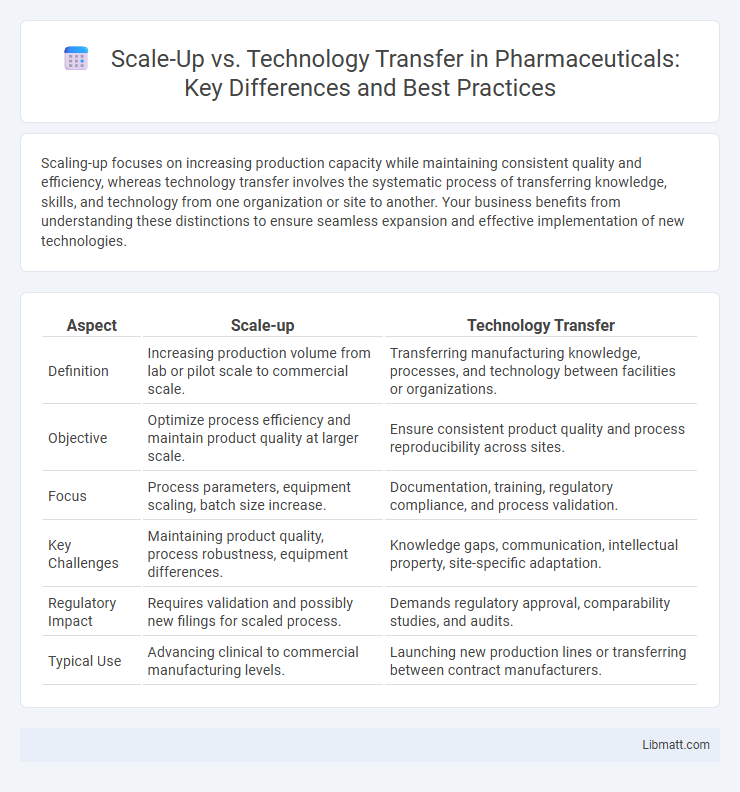

Scaling-up focuses on increasing production capacity while maintaining consistent quality and efficiency, whereas technology transfer involves the systematic process of transferring knowledge, skills, and technology from one organization or site to another. Your business benefits from understanding these distinctions to ensure seamless expansion and effective implementation of new technologies.

Table of Comparison

| Aspect | Scale-up | Technology Transfer |

|---|---|---|

| Definition | Increasing production volume from lab or pilot scale to commercial scale. | Transferring manufacturing knowledge, processes, and technology between facilities or organizations. |

| Objective | Optimize process efficiency and maintain product quality at larger scale. | Ensure consistent product quality and process reproducibility across sites. |

| Focus | Process parameters, equipment scaling, batch size increase. | Documentation, training, regulatory compliance, and process validation. |

| Key Challenges | Maintaining product quality, process robustness, equipment differences. | Knowledge gaps, communication, intellectual property, site-specific adaptation. |

| Regulatory Impact | Requires validation and possibly new filings for scaled process. | Demands regulatory approval, comparability studies, and audits. |

| Typical Use | Advancing clinical to commercial manufacturing levels. | Launching new production lines or transferring between contract manufacturers. |

Introduction to Scale-up and Technology Transfer

Scale-up involves increasing the production volume of a process or product while maintaining quality and efficiency, crucial for meeting market demand. Technology transfer refers to the systematic process of transferring scientific findings or innovations from research institutions to commercial entities for practical application. Both scale-up and technology transfer are essential steps in bridging laboratory research and full-scale industrial production.

Defining Scale-up: Purpose and Processes

Scale-up refers to the process of increasing the production capacity of a product or technology to meet market demand while maintaining quality and efficiency. This phase involves optimizing equipment, refining operational parameters, and ensuring regulatory compliance to transition from pilot-scale to full-scale manufacturing. Effective scale-up reduces costs, minimizes risks, and accelerates time-to-market by addressing challenges unique to large-scale production.

Understanding Technology Transfer: Key Concepts

Technology transfer involves the systematic process of moving innovations from research laboratories to commercial application, encompassing intellectual property management, licensing, and collaboration between academia and industry. Scale-up focuses on expanding production capabilities while maintaining product quality and process efficiency, bridging the gap between pilot experiments and full-scale manufacturing. Understanding technology transfer is crucial for your successful commercialization strategy, ensuring seamless transition from invention to market-ready solutions.

Importance in Pharmaceutical and Manufacturing Industries

Scale-up and technology transfer play crucial roles in the pharmaceutical and manufacturing industries by ensuring the seamless transition from laboratory research to full-scale production. Efficient scale-up processes improve product consistency and quality while reducing time-to-market for new drugs and devices. Your success depends on effective technology transfer strategies that minimize risks, optimize resources, and maintain regulatory compliance during production expansion.

Key Differences Between Scale-up and Technology Transfer

Scale-up involves increasing production volume while maintaining product quality and process efficiency, typically within the same facility using established technology. Technology transfer is the systematic process of transferring knowledge, skills, and technologies from one organization or location to another, often requiring adaptation to new environments or equipment. Key differences lie in scale-up focusing on expansion and optimization, whereas technology transfer emphasizes knowledge exchange and adaptation for replication.

Challenges Faced During Scale-up

Challenges faced during scale-up include maintaining product consistency, managing increased operational complexity, and ensuring regulatory compliance across larger production volumes. Technology transfer often encounters difficulties in knowledge transfer, process adaptation to new environments, and aligning team expertise. Your ability to address these challenges determines the efficiency and success of moving from pilot to full-scale production.

Barriers in Technology Transfer Implementation

Barriers in technology transfer implementation often include differences in organizational culture, lack of skilled personnel, and inadequate communication channels between originators and adopters. Intellectual property concerns and regulatory compliance issues also impede seamless technology adoption. Your success in overcoming these obstacles depends on strategic planning and fostering collaborative partnerships that facilitate knowledge exchange.

Best Practices for Successful Scale-up

Successful scale-up requires meticulous process optimization, emphasizing reproducibility and quality control to maintain product integrity from pilot to commercial production. Implementing robust analytical methods and leveraging advanced automation tools ensures consistent scalability while minimizing operational risks. Cross-functional collaboration and thorough documentation facilitate smooth technology transfer, aligning R&D with manufacturing capabilities.

Strategies for Effective Technology Transfer

Effective technology transfer strategies emphasize clear communication of technical knowledge, protection of intellectual property rights, and adaptation to local regulatory environments. Establishing strong partnerships between research institutions and industry accelerates commercialization and scalability. Incorporating comprehensive training programs ensures successful integration of technology within recipient organizations, maximizing efficiency during scale-up.

Future Trends in Scale-up and Technology Transfer

Future trends in scale-up and technology transfer emphasize increased automation and digitalization to enhance efficiency and reduce time-to-market in biopharmaceutical manufacturing. Integration of AI-driven predictive analytics optimizes process scalability while ensuring seamless knowledge transfer across development stages. Growing adoption of modular and flexible manufacturing platforms supports rapid adaptation to evolving regulatory requirements and market demands.

Scale-up vs Technology transfer Infographic

libmatt.com

libmatt.com