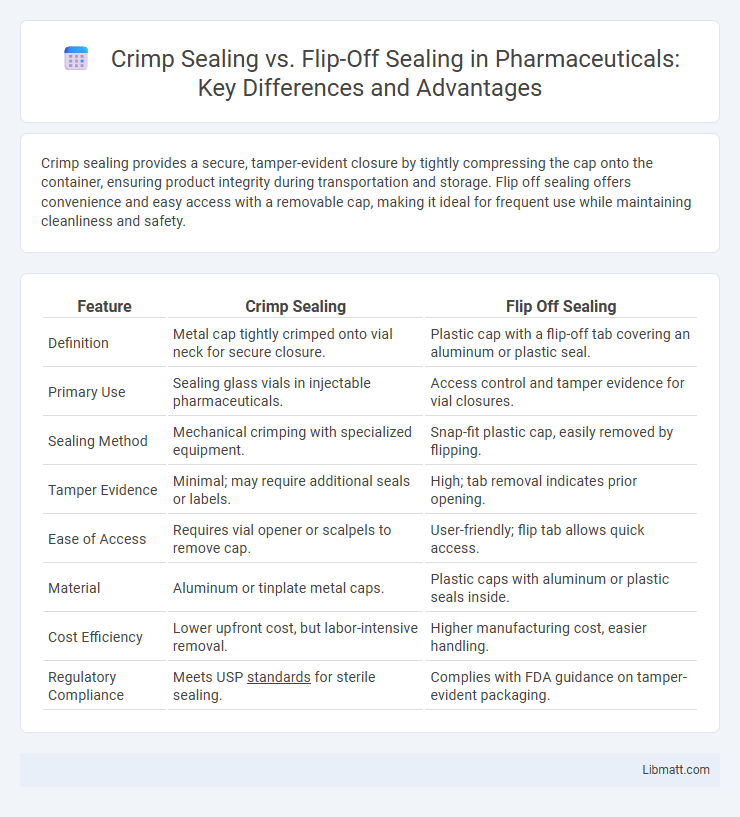

Crimp sealing provides a secure, tamper-evident closure by tightly compressing the cap onto the container, ensuring product integrity during transportation and storage. Flip off sealing offers convenience and easy access with a removable cap, making it ideal for frequent use while maintaining cleanliness and safety.

Table of Comparison

| Feature | Crimp Sealing | Flip Off Sealing |

|---|---|---|

| Definition | Metal cap tightly crimped onto vial neck for secure closure. | Plastic cap with a flip-off tab covering an aluminum or plastic seal. |

| Primary Use | Sealing glass vials in injectable pharmaceuticals. | Access control and tamper evidence for vial closures. |

| Sealing Method | Mechanical crimping with specialized equipment. | Snap-fit plastic cap, easily removed by flipping. |

| Tamper Evidence | Minimal; may require additional seals or labels. | High; tab removal indicates prior opening. |

| Ease of Access | Requires vial opener or scalpels to remove cap. | User-friendly; flip tab allows quick access. |

| Material | Aluminum or tinplate metal caps. | Plastic caps with aluminum or plastic seals inside. |

| Cost Efficiency | Lower upfront cost, but labor-intensive removal. | Higher manufacturing cost, easier handling. |

| Regulatory Compliance | Meets USP standards for sterile sealing. | Complies with FDA guidance on tamper-evident packaging. |

Introduction to Crimp Sealing and Flip Off Sealing

Crimp Sealing involves compressing a metal cap around a container's neck to create a secure, tamper-evident seal commonly used in pharmaceutical vials. Flip Off Sealing features a protective plastic cap that snaps onto the metal crimp seal, enabling easy removal while maintaining the integrity of the product. Your choice between these methods depends on factors such as storage requirements, ease of access, and tamper evidence needs.

Overview of Vial Closure Systems

Crimp sealing and flip-off sealing are primary vial closure systems used in pharmaceutical packaging to ensure product integrity and sterility. Crimp sealing involves deforming an aluminum cap around the vial neck to create a secure, tamper-evident seal, while flip-off sealing features a plastic cap over a metal aluminum seal that can be easily removed for access. Both systems offer distinct advantages in maintaining vial closure integrity, preventing contamination, and facilitating ease of use in clinical and production environments.

How Crimp Sealing Works

Crimp sealing secures vial closures by deforming the aluminum cap around the vial neck, creating a tight, tamper-evident seal that preserves sterility and prevents contamination. This process uses a specialized crimping tool or machine to apply uniform pressure, ensuring the closure is firmly affixed without damaging the vial or contents. Understanding how crimp sealing works can help you select the best packaging for pharmaceutical or laboratory applications requiring secure, leak-proof seals.

How Flip Off Sealing Works

Flip Off sealing features a plastic cap that fits snugly over a metal or plastic cap, securing vials for sterile pharmaceutical packaging. Your access is granted by simply flipping the colored plastic cap upwards, revealing a metal seal beneath that protects the vial's contents. This method preserves sterility and allows easy, tamper-evident access compared to traditional crimp sealing.

Key Differences Between Crimp and Flip Off Seals

Crimp sealing involves mechanically compressing a metal cap onto a vial, creating a tight, tamper-evident seal ideal for sterile environments. Flip off sealing features a plastic cap that snaps onto the vial's metal cap, allowing easy removal and resealing without requiring specialized tools. Your choice between crimp and flip off seals impacts packaging security, convenience, and integrity, depending on the specific pharmaceutical or laboratory application.

Advantages of Crimp Sealing

Crimp sealing offers superior tamper-evidence and airtight protection, making it ideal for preserving product freshness and ensuring safety. Its strong mechanical bond enhances packaging durability during transportation and storage, reducing the risk of contamination. You benefit from cost-effective application processes that improve sealing speed and consistency over flip-off sealing methods.

Advantages of Flip Off Sealing

Flip Off Sealing provides a tamper-evident closure that ensures product integrity and consumer safety, making it ideal for pharmaceutical and cosmetic packaging. This sealing method allows for quick access without tools, enhancing user convenience and reducing time during product application. Your packaging will benefit from improved hygiene and professional appearance, as Flip Off Seals are designed to minimize contamination risks while offering a secure and reliable seal.

Applications in Pharmaceutical Packaging

Crimp sealing is widely used in pharmaceutical packaging for securing glass vials containing injectable drugs, ensuring an airtight, tamper-evident closure that maintains sterility and stability. Flip off sealing provides a convenient, tamper-evident metal cap with a plastic flip-off tab, commonly applied in multi-dose vials to facilitate easy access while preserving product integrity. Both methods support regulatory compliance and product safety in injectable drug delivery systems.

Factors to Consider When Choosing a Sealing Method

When choosing between crimp sealing and flip-off sealing, factors such as the type of container, medication stability, and tamper-evidence requirements play a crucial role. Crimp sealing offers a strong, tamper-resistant closure ideal for injectable vials, while flip-off sealing provides easy access and visual assurance of product integrity. Your decision should also consider manufacturing speed, compatibility with sealing equipment, and regulatory compliance for pharmaceutical packaging.

Conclusion: Selecting the Right Sealing Technique

Choosing between crimp sealing and flip off sealing depends on application requirements such as security, tamper evidence, and ease of access. Crimp sealing offers a robust, tamper-evident closure ideal for pharmaceutical vials, while flip off sealing provides convenience and quick access for consumer products. Prioritizing factors like aseptic conditions, regulatory compliance, and user experience ensures the selection of the most suitable sealing technique.

Crimp Sealing vs Flip Off Sealing Infographic

libmatt.com

libmatt.com