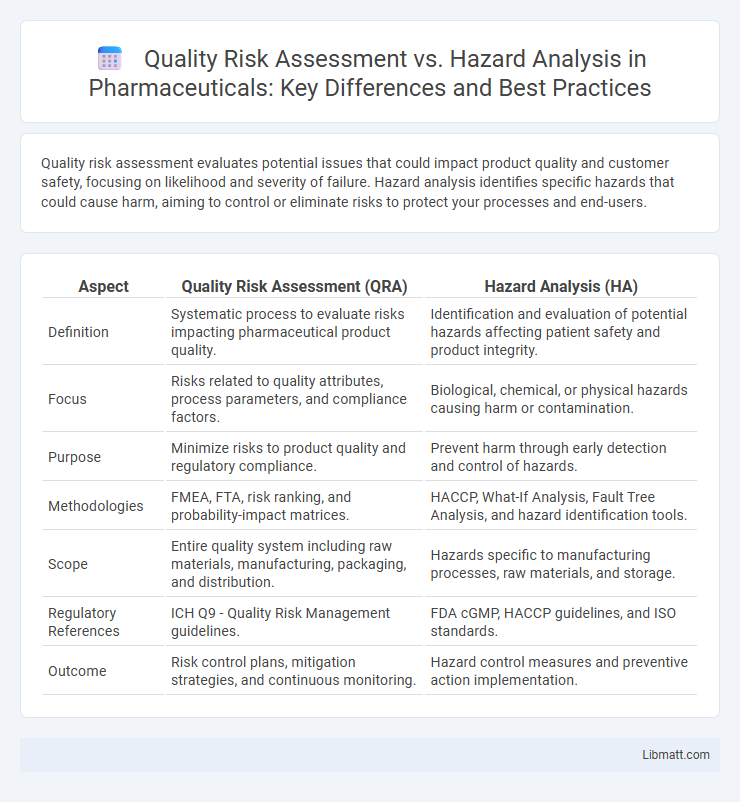

Quality risk assessment evaluates potential issues that could impact product quality and customer safety, focusing on likelihood and severity of failure. Hazard analysis identifies specific hazards that could cause harm, aiming to control or eliminate risks to protect your processes and end-users.

Table of Comparison

| Aspect | Quality Risk Assessment (QRA) | Hazard Analysis (HA) |

|---|---|---|

| Definition | Systematic process to evaluate risks impacting pharmaceutical product quality. | Identification and evaluation of potential hazards affecting patient safety and product integrity. |

| Focus | Risks related to quality attributes, process parameters, and compliance factors. | Biological, chemical, or physical hazards causing harm or contamination. |

| Purpose | Minimize risks to product quality and regulatory compliance. | Prevent harm through early detection and control of hazards. |

| Methodologies | FMEA, FTA, risk ranking, and probability-impact matrices. | HACCP, What-If Analysis, Fault Tree Analysis, and hazard identification tools. |

| Scope | Entire quality system including raw materials, manufacturing, packaging, and distribution. | Hazards specific to manufacturing processes, raw materials, and storage. |

| Regulatory References | ICH Q9 - Quality Risk Management guidelines. | FDA cGMP, HACCP guidelines, and ISO standards. |

| Outcome | Risk control plans, mitigation strategies, and continuous monitoring. | Hazard control measures and preventive action implementation. |

Introduction to Quality Risk Assessment and Hazard Analysis

Quality risk assessment identifies, evaluates, and controls risks affecting product quality and patient safety throughout the lifecycle, using systematic tools like Failure Mode and Effects Analysis (FMEA). Hazard analysis focuses on detecting potential sources of contamination or process failures, commonly applied in Hazard Analysis and Critical Control Points (HACCP) systems within manufacturing environments. You can enhance compliance and safety by integrating both methodologies to address quality and safety risks comprehensively.

Defining Quality Risk Assessment

Quality Risk Assessment is a systematic process used to identify, evaluate, and control risks that could impact the quality of products or processes in regulated industries. Unlike hazard analysis, which primarily focuses on identifying potential sources of harm, Quality Risk Assessment evaluates the likelihood and severity of quality failures to prioritize risk mitigation efforts. Your organization benefits by applying thorough Quality Risk Assessment to ensure compliance, enhance product safety, and maintain customer trust.

Understanding Hazard Analysis

Hazard analysis is a systematic process used to identify and evaluate potential sources of harm within a product or process, often applying techniques such as Failure Mode and Effects Analysis (FMEA) or Hazard and Operability Study (HAZOP). It focuses on recognizing hazards that could lead to safety, health, or environmental issues, facilitating the development of control measures to mitigate risks. Unlike quality risk assessment, which encompasses a broader evaluation of risks affecting product quality and compliance, hazard analysis specifically targets the identification and management of hazards to ensure safety and operational integrity.

Key Differences Between Risk Assessment and Hazard Analysis

Quality risk assessment evaluates the probability and impact of potential failures on product quality, prioritizing risk control measures to ensure compliance with regulatory standards like ICH Q9. Hazard analysis systematically identifies and evaluates specific hazards, such as biological, chemical, or physical threats, focusing on preventing harm by implementing critical control points based on methodologies like HACCP. The key differences lie in the scope and application: risk assessment emphasizes overall quality impact and risk ranking, while hazard analysis concentrates on detecting and mitigating discrete hazards to safety and quality.

Importance in Regulatory Compliance

Quality risk assessment and hazard analysis are essential components in regulatory compliance, ensuring that potential risks and hazards are systematically identified, evaluated, and controlled to meet industry standards. Regulatory agencies like the FDA and EMA require comprehensive risk management processes to prevent product defects and ensure consumer safety, making these assessments critical for your manufacturing and quality assurance protocols. Effective implementation of these strategies mitigates compliance violations, reduces recalls, and supports continuous improvement in product quality.

Methodologies Used in Quality Risk Assessment

Quality risk assessment methodologies primarily include Failure Mode and Effects Analysis (FMEA), Fault Tree Analysis (FTA), and Risk Ranking and Filtering, each focusing on identifying, evaluating, and prioritizing potential risks in manufacturing and product quality. These structured approaches systematically analyze risk factors by estimating severity, probability, and detectability to ensure product safety and compliance. Incorporating data-driven decision-making tools enhances the robustness of quality risk assessments compared to hazard analysis, which concentrates on identifying potential hazards without always quantifying risk severity or occurrence likelihood.

Hazard Analysis Techniques and Tools

Hazard analysis techniques such as Failure Mode and Effects Analysis (FMEA), Fault Tree Analysis (FTA), and Hazard and Operability Study (HAZOP) systematically identify and evaluate potential hazards within a process or system. Quality risk assessment integrates these tools to quantify and prioritize risks based on severity, occurrence, and detectability, enhancing decision-making for quality control. Utilizing software tools like RiskWatch or Isograph enables efficient documentation, risk scoring, and mitigation planning, bridging hazard analysis and comprehensive quality risk management.

Applications in the Pharmaceutical Industry

Quality risk assessment in the pharmaceutical industry focuses on identifying, evaluating, and controlling risks to product quality throughout the manufacturing process to ensure compliance with regulatory standards such as FDA and EMA guidelines. Hazard analysis, particularly Hazard Analysis and Critical Control Points (HACCP), is applied to systematically identify and mitigate potential biological, chemical, and physical hazards that may compromise product safety. Both methodologies are integral to Good Manufacturing Practices (GMP) and are utilized to safeguard drug efficacy, patient safety, and regulatory compliance during drug development and production.

Integrating Risk Assessment and Hazard Analysis

Integrating risk assessment and hazard analysis enhances your ability to identify, evaluate, and mitigate potential dangers in complex systems, optimizing safety and compliance. Quality risk assessment prioritizes control measures based on the likelihood and severity of risks, while hazard analysis systematically identifies possible sources of harm. Combining these methodologies ensures a comprehensive evaluation that strengthens decision-making and improves overall risk management effectiveness.

Best Practices for Effective Implementation

Quality risk assessment emphasizes systematic evaluation of potential risks affecting product quality, using tools like FMEA and HACCP to prioritize mitigation based on severity and likelihood. Hazard analysis focuses on identifying and controlling biological, chemical, and physical hazards through detailed process mapping and critical control points. Best practices for effective implementation include cross-functional team collaboration, thorough documentation, regular review cycles, and alignment with regulatory guidelines such as ICH Q9 and ISO 31000 standards.

Quality risk assessment vs hazard analysis Infographic

libmatt.com

libmatt.com