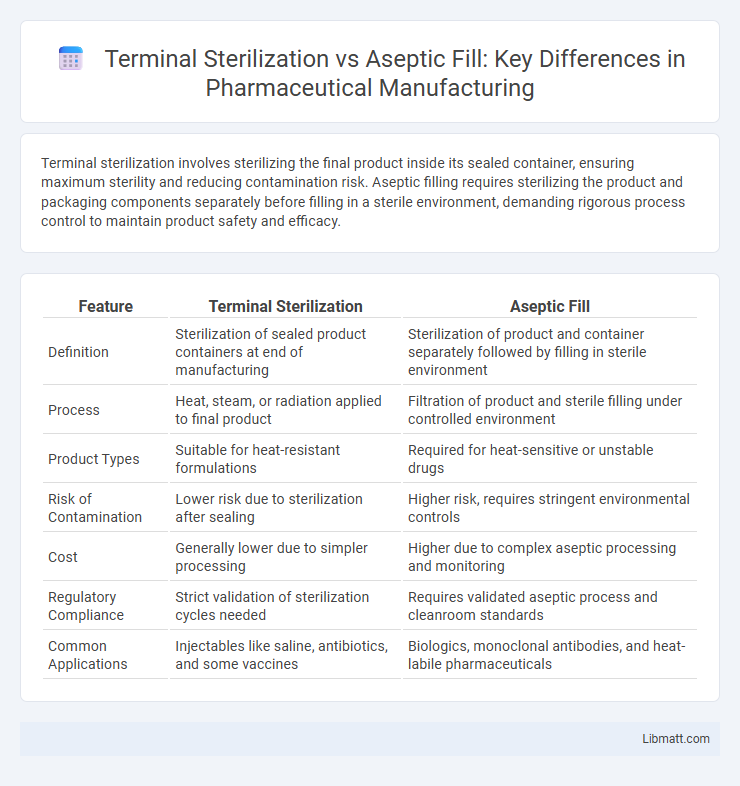

Terminal sterilization involves sterilizing the final product inside its sealed container, ensuring maximum sterility and reducing contamination risk. Aseptic filling requires sterilizing the product and packaging components separately before filling in a sterile environment, demanding rigorous process control to maintain product safety and efficacy.

Table of Comparison

| Feature | Terminal Sterilization | Aseptic Fill |

|---|---|---|

| Definition | Sterilization of sealed product containers at end of manufacturing | Sterilization of product and container separately followed by filling in sterile environment |

| Process | Heat, steam, or radiation applied to final product | Filtration of product and sterile filling under controlled environment |

| Product Types | Suitable for heat-resistant formulations | Required for heat-sensitive or unstable drugs |

| Risk of Contamination | Lower risk due to sterilization after sealing | Higher risk, requires stringent environmental controls |

| Cost | Generally lower due to simpler processing | Higher due to complex aseptic processing and monitoring |

| Regulatory Compliance | Strict validation of sterilization cycles needed | Requires validated aseptic process and cleanroom standards |

| Common Applications | Injectables like saline, antibiotics, and some vaccines | Biologics, monoclonal antibodies, and heat-labile pharmaceuticals |

Introduction to Sterile Manufacturing Processes

Terminal sterilization involves sterilizing the final product in its sealed container using methods such as steam, radiation, or gas, ensuring high sterility assurance levels. Aseptic fill process requires sterilizing the product and container separately before sterile filling in a controlled environment, minimizing contamination risks during handling. Both methods are critical in sterile manufacturing, with terminal sterilization preferred for its robust sterility assurance when compatible with product stability.

Defining Terminal Sterilization

Terminal sterilization is a sterilization process performed on a product in its final container, ensuring microbial inactivation after packaging is sealed. This method is highly effective for pharmaceutical products, offering robust sterility assurance compared to aseptic fill, which sterilizes components separately before filling. Your choice between terminal sterilization and aseptic fill impacts product safety, regulatory compliance, and manufacturing complexity.

Understanding Aseptic Fill Techniques

Aseptic fill techniques involve sterilizing the product and packaging components separately before combining them in a sterile environment to prevent contamination. This method requires advanced cleanroom facilities and strict environmental controls to maintain sterility throughout the filling and sealing processes. Terminal sterilization, by contrast, sterilizes the product within its final container, often using heat or radiation, but may not be suitable for heat-sensitive pharmaceuticals that benefit from aseptic processing.

Key Differences Between Terminal Sterilization and Aseptic Fill

Terminal sterilization involves sterilizing the product in its final sealed container, ensuring high sterilization assurance and reduced contamination risk. Aseptic fill requires sterilizing all components separately before filling and sealing in a sterile environment, emphasizing strict environmental controls and operator skill. Your choice depends on product heat sensitivity and facility capabilities, with terminal sterilization often preferred for robust pharmaceuticals and aseptic fill for heat-sensitive biologics.

Regulatory Guidelines and Industry Standards

Terminal sterilization is favored by regulatory agencies such as the FDA and EMA due to its robust validation under USP <1211> and ISO 11737 standards, ensuring greater sterility assurance levels. Aseptic filling requires stringent control measures guided by GMP regulations, including FDA's aseptic processing guidelines and Annex 1 of the EU GMP, emphasizing environmental monitoring and operator qualifications to minimize contamination risks. Industry standards prioritize terminal sterilization when feasible, but aseptic fill remains essential for heat-sensitive products, demanding comprehensive process validation and risk assessment per PDA Technical Reports and PIC/S guidelines.

Advantages of Terminal Sterilization

Terminal sterilization offers superior assurance of microbial safety by sterilizing the final sealed product, significantly reducing contamination risks compared to aseptic filling. This method is more cost-effective and less complex since it eliminates the need for strict environmental controls and specialized aseptic techniques during filling. Regulatory agencies often prefer terminal sterilization for its proven reliability in maintaining product sterility and extending shelf life.

Advantages of Aseptic Fill

Aseptic fill offers significant advantages in maintaining product integrity by filling sterilized containers in a sterile environment, reducing potential exposure to contaminants. This method is essential for heat-sensitive pharmaceuticals and biologics that cannot withstand terminal sterilization processes. It enables precise control over sterility assurance levels, ensuring high product safety and efficacy.

Common Applications in Pharmaceutical Manufacturing

Terminal sterilization is widely applied in pharmaceutical manufacturing for heat-stable products such as injectables, ophthalmic solutions, and creams, offering robust microbial kill and extended product shelf life. Aseptic fill, preferred for heat-sensitive biologics, vaccines, and protein-based therapies, ensures sterility by combining sterile filtration with sterile filling environments without exposing the product to high temperatures. Your choice between these methods depends on the thermal stability of the drug and its packaging requirements to maintain efficacy and safety.

Risk Assessment and Quality Control

Terminal sterilization offers a robust risk assessment profile by effectively eliminating viable microorganisms after product filling, thereby reducing contamination during the filling process. Quality control for terminal sterilization involves rigorous validation of sterilization parameters such as time, temperature, and radiation dose to ensure complete microbial inactivation. In contrast, aseptic filling requires extensive environmental monitoring, stringent process controls, and continuous risk assessments to maintain sterility throughout filling, relying heavily on filtration and controlled cleanroom conditions to prevent contamination before sealing.

Choosing the Optimal Sterilization Method

Choosing the optimal sterilization method between terminal sterilization and aseptic fill depends on product stability, packaging compatibility, and regulatory requirements. Terminal sterilization offers higher sterility assurance by sterilizing the product in its final container, but may not be suitable for heat-sensitive products. Your decision should balance microbial safety, product integrity, and process feasibility to ensure maximum efficacy and compliance.

Terminal sterilization vs aseptic fill Infographic

libmatt.com

libmatt.com