A diluent is an inactive substance used to bulk up or dilute the active ingredient in a formulation, ensuring proper dosage and consistency, while a binder is a component that helps hold the ingredients together, providing structural integrity to tablets or granules. Understanding the difference between a diluent and binder can improve your control over the texture and effectiveness of pharmaceutical or food products.

Table of Comparison

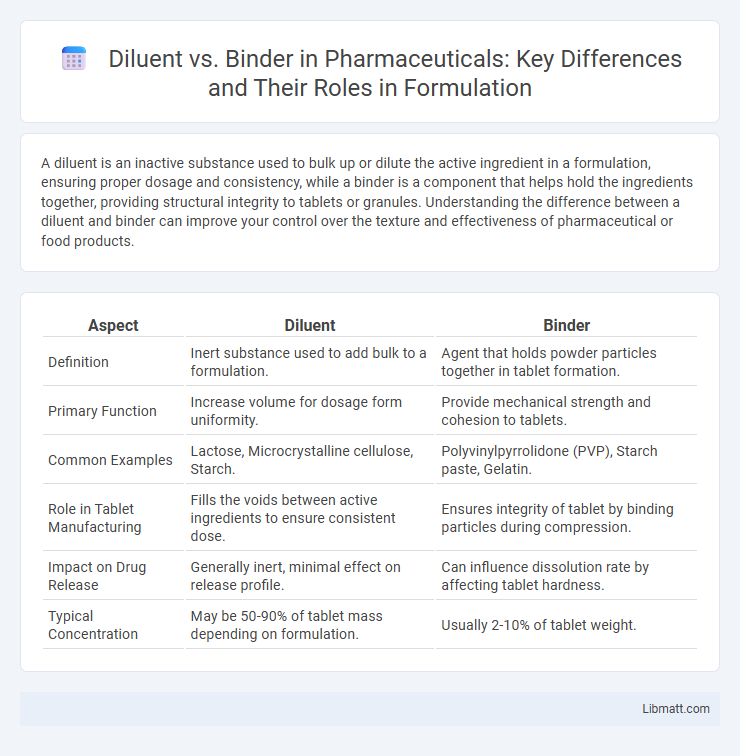

| Aspect | Diluent | Binder |

|---|---|---|

| Definition | Inert substance used to add bulk to a formulation. | Agent that holds powder particles together in tablet formation. |

| Primary Function | Increase volume for dosage form uniformity. | Provide mechanical strength and cohesion to tablets. |

| Common Examples | Lactose, Microcrystalline cellulose, Starch. | Polyvinylpyrrolidone (PVP), Starch paste, Gelatin. |

| Role in Tablet Manufacturing | Fills the voids between active ingredients to ensure consistent dose. | Ensures integrity of tablet by binding particles during compression. |

| Impact on Drug Release | Generally inert, minimal effect on release profile. | Can influence dissolution rate by affecting tablet hardness. |

| Typical Concentration | May be 50-90% of tablet mass depending on formulation. | Usually 2-10% of tablet weight. |

Introduction to Diluent and Binder

Diluent and binder are essential components in pharmaceutical formulations, where diluents primarily serve as inactive substances used to increase the volume of a drug to create a manageable dosage form. Binders, on the other hand, act as adhesive agents that help hold the ingredients of a tablet together, ensuring stability and integrity during manufacturing and handling. Understanding the roles of your diluent and binder is crucial for optimizing drug delivery and achieving consistent therapeutic effects.

Definition of Diluent

A diluent is an inactive substance used to dilute active ingredients in pharmaceutical formulations, ensuring uniformity and ease of processing. It often consists of materials like lactose, microcrystalline cellulose, or starch that provide bulk without affecting the drug's therapeutic effect. Unlike binders, which promote adhesion of particles, diluents primarily serve to increase volume and improve handling of the dosage form.

Definition of Binder

A binder is a substance used in formulations to hold ingredients together, providing cohesion and structural integrity to tablets, pills, or powders. Unlike diluents, which primarily add volume and bulk without affecting the mechanical strength, binders ensure that your final product remains intact during processing and handling. Common examples of binders include starch, cellulose derivatives, and synthetic polymers.

Key Differences Between Diluent and Binder

Diluent primarily serves as an inactive filler that increases the bulk of a formulation without affecting its chemical properties, whereas binder functions to hold the ingredients together, ensuring cohesion and mechanical strength in tablets or pellets. Diluents are often composed of substances like lactose, cellulose, or starch, while binders include agents such as polyvinylpyrrolidone (PVP) or gelatin. The key difference lies in their roles: diluents provide volume, whereas binders contribute to the integrity and stability of the final product.

Common Uses of Diluents

Diluents are commonly used in pharmaceuticals and food industries to increase the volume of a product without affecting its chemical properties, enabling easier handling and precise dosing. In tablet formulation, diluents such as lactose, microcrystalline cellulose, and starch improve tablet size and consistency. These substances serve as inert fillers that maintain stability and uniformity in drug delivery systems.

Common Applications for Binders

Binders are essential in pharmaceutical tablet formulation, providing cohesion to powder particles and ensuring tablet integrity during manufacturing and use. Common applications for binders include granulation processes, where they improve particle adhesion and enhance mechanical strength, and direct compression methods, where they facilitate uniform blending and compressibility. Widely used binders such as cellulose derivatives, polyvinylpyrrolidone (PVP), and starch derivatives contribute to controlled drug release and dosage uniformity in oral solid dosage forms.

Importance of Selection: Diluent vs Binder

Selecting the right diluent or binder is crucial in pharmaceutical formulations to ensure optimal drug stability, bioavailability, and patient compliance. Diluents primarily increase the tablet volume without affecting its therapeutic effect, while binders provide cohesion between ingredients, enhancing the tablet's mechanical strength and integrity during manufacturing. Understanding your formulation's specific needs helps determine the appropriate balance between diluents and binders to achieve consistent drug delivery and performance.

Factors Affecting Choice of Diluent or Binder

Factors affecting the choice of diluent or binder include solubility, compatibility with the active pharmaceutical ingredient (API), and impact on drug release profile. The physical and chemical properties such as particle size, flowability, and compressibility also influence formulation stability and tablet integrity. Understanding Your specific formulation needs ensures optimal selection for efficacy and manufacturing efficiency.

Impact on Product Performance

Diluent and binder significantly affect product performance by influencing the mechanical strength and stability of formulations. Diluent primarily adjusts the volume and density without altering binding properties, whereas binder enhances cohesion, improving tablet hardness and disintegration time. Optimizing their ratios is critical for achieving desired drug release profiles and ensuring consistent efficacy.

Conclusion: Choosing the Right Component

Choosing the right component between diluent and binder depends on the formulation's specific requirements for texture, stability, and dissolution. Diluents primarily serve to increase bulk without affecting the chemical properties, while binders provide cohesion to hold ingredients together. Optimizing tablet quality and performance requires balancing these roles based on the desired drug release profile and mechanical strength.

Diluent vs binder Infographic

libmatt.com

libmatt.com