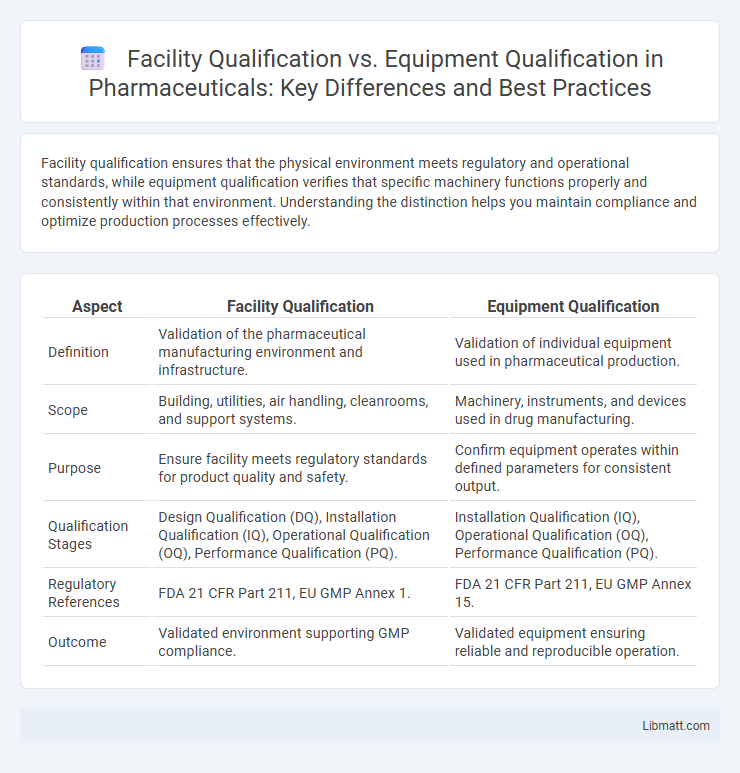

Facility qualification ensures that the physical environment meets regulatory and operational standards, while equipment qualification verifies that specific machinery functions properly and consistently within that environment. Understanding the distinction helps you maintain compliance and optimize production processes effectively.

Table of Comparison

| Aspect | Facility Qualification | Equipment Qualification |

|---|---|---|

| Definition | Validation of the pharmaceutical manufacturing environment and infrastructure. | Validation of individual equipment used in pharmaceutical production. |

| Scope | Building, utilities, air handling, cleanrooms, and support systems. | Machinery, instruments, and devices used in drug manufacturing. |

| Purpose | Ensure facility meets regulatory standards for product quality and safety. | Confirm equipment operates within defined parameters for consistent output. |

| Qualification Stages | Design Qualification (DQ), Installation Qualification (IQ), Operational Qualification (OQ), Performance Qualification (PQ). | Installation Qualification (IQ), Operational Qualification (OQ), Performance Qualification (PQ). |

| Regulatory References | FDA 21 CFR Part 211, EU GMP Annex 1. | FDA 21 CFR Part 211, EU GMP Annex 15. |

| Outcome | Validated environment supporting GMP compliance. | Validated equipment ensuring reliable and reproducible operation. |

Understanding Facility Qualification

Facility qualification ensures that the entire building environment meets regulatory standards for production, including controlled temperature, humidity, air quality, and cleanliness. It verifies that your facility's infrastructure supports consistent product quality and compliance with Good Manufacturing Practices (GMP). Equipment qualification focuses specifically on individual machines, while facility qualification validates the overall environment where equipment operates.

Defining Equipment Qualification

Equipment qualification is the documented process ensuring that machinery and tools meet predetermined specifications and operate consistently within defined limits. It includes Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) to verify proper installation, functionality, and performance under routine conditions. Your compliance with equipment qualification standards is essential for maintaining product quality and regulatory adherence.

Key Differences Between Facility and Equipment Qualification

Facility qualification ensures the entire environment meets regulatory standards for production, focusing on aspects such as HVAC systems, cleanliness, and layout to prevent contamination. Equipment qualification specifically validates individual machinery performance characteristics including installation, operational, and performance qualifications (IQ, OQ, PQ). The key differences lie in scope: facility qualification addresses the overall production environment, while equipment qualification targets the functionality and reliability of specific equipment within that environment.

Regulatory Requirements: Facility vs Equipment

Regulatory requirements for facility qualification focus on validating the entire production environment to ensure it meets cleanliness, environmental controls, and safety standards critical for product quality and compliance. Equipment qualification requires demonstrating that individual machines perform consistently according to predefined specifications, including installation, operational, and performance qualifications. Your compliance strategy must address both facility and equipment qualifications distinctly to satisfy regulatory agencies such as the FDA and EMA, ensuring comprehensive validation.

Qualification Stages: Design, Installation, Operation, Performance

Facility qualification and equipment qualification both follow crucial stages: Design, Installation, Operation, and Performance. Facility qualification ensures that the entire environment meets regulatory standards, focusing on structural design, utility systems installation, operational protocols, and performance validation under real conditions. Equipment qualification targets specific machinery, verifying its design specifications, proper installation, operational functionality, and consistent performance to meet production quality requirements.

Documentation Needed for Qualification

Facility qualification documentation includes validation protocols, design specifications, and environmental monitoring records to ensure the overall site meets operational standards. Equipment qualification requires detailed installation, operational, and performance qualification documents, calibration certificates, and maintenance logs to verify each instrument functions correctly. Proper documentation streamlines your compliance process and ensures regulatory standards are consistently met.

Risk Assessment in Facility and Equipment Qualification

Risk assessment in facility qualification focuses on evaluating structural, environmental, and utility systems to ensure they meet operational safety and compliance standards. Equipment qualification risk assessment targets the functionality, calibration, and maintenance of machinery to minimize failure risks and ensure consistent performance. Integrating both assessments helps you establish a robust quality assurance framework that mitigates potential hazards across your entire production environment.

Common Challenges in Qualification Processes

Facility qualification and equipment qualification both face common challenges such as ensuring compliance with regulatory standards like FDA and EMA, managing complex documentation requirements, and maintaining traceability throughout the validation lifecycle. Calibration accuracy and environmental control pose recurring difficulties, especially in validating HVAC systems for facilities versus precision instruments for equipment. Cross-functional collaboration is critical to address discrepancies in protocols and to align qualification efforts with overall quality assurance frameworks.

Best Practices for Facility and Equipment Qualification

Facility qualification ensures that the physical environment, including HVAC systems, utility services, and contamination controls, meets regulatory standards essential for product quality and safety. Equipment qualification focuses on verifying that machines and instruments perform consistently within defined parameters through Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ). To optimize your qualification process, implement comprehensive documentation, risk-based approaches, and routine maintenance schedules to ensure compliance and operational efficiency.

Importance of Qualification in Quality Assurance

Facility qualification and equipment qualification are critical components in maintaining robust quality assurance standards within manufacturing and laboratory environments. Proper qualification ensures that your facilities and equipment operate consistently under specified conditions, minimizing variability and risk of contamination. This process guarantees product integrity, regulatory compliance, and ultimately safeguards consumer safety by validating that all systems meet intended design and performance criteria.

Facility qualification vs equipment qualification Infographic

libmatt.com

libmatt.com