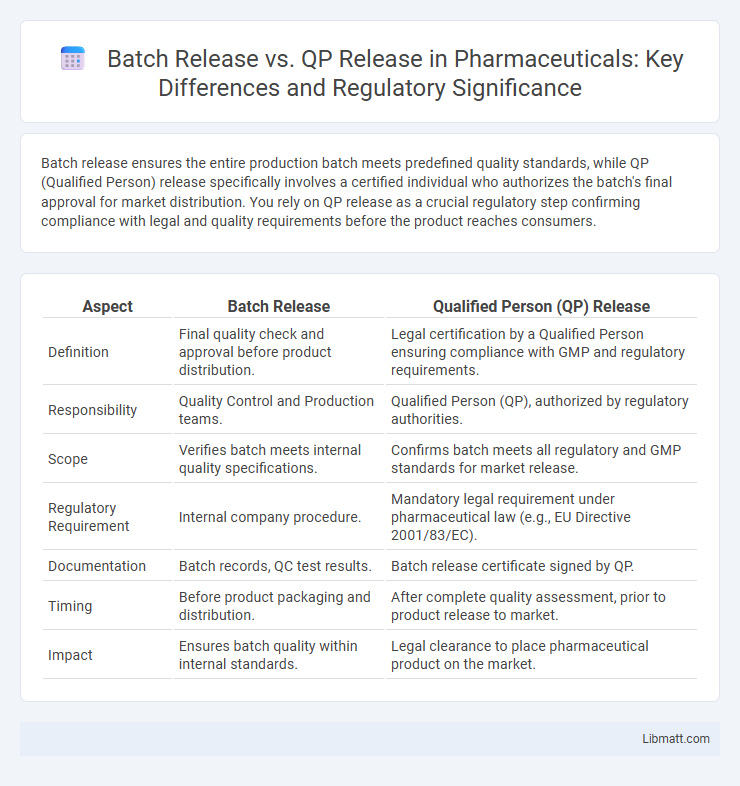

Batch release ensures the entire production batch meets predefined quality standards, while QP (Qualified Person) release specifically involves a certified individual who authorizes the batch's final approval for market distribution. You rely on QP release as a crucial regulatory step confirming compliance with legal and quality requirements before the product reaches consumers.

Table of Comparison

| Aspect | Batch Release | Qualified Person (QP) Release |

|---|---|---|

| Definition | Final quality check and approval before product distribution. | Legal certification by a Qualified Person ensuring compliance with GMP and regulatory requirements. |

| Responsibility | Quality Control and Production teams. | Qualified Person (QP), authorized by regulatory authorities. |

| Scope | Verifies batch meets internal quality specifications. | Confirms batch meets all regulatory and GMP standards for market release. |

| Regulatory Requirement | Internal company procedure. | Mandatory legal requirement under pharmaceutical law (e.g., EU Directive 2001/83/EC). |

| Documentation | Batch records, QC test results. | Batch release certificate signed by QP. |

| Timing | Before product packaging and distribution. | After complete quality assessment, prior to product release to market. |

| Impact | Ensures batch quality within internal standards. | Legal clearance to place pharmaceutical product on the market. |

Understanding Batch Release: Definition and Process

Batch release is the formal process of reviewing and approving a pharmaceutical batch for distribution, ensuring it meets all quality and regulatory requirements. It involves evaluating comprehensive documentation, quality control test results, and compliance with manufacturing standards to verify product safety and efficacy. Your understanding of batch release is crucial for maintaining product integrity before it reaches the market.

What is QP Release? Key Responsibilities

QP release, or Qualified Person release, is a critical final step in pharmaceutical batch release ensuring product compliance with regulatory standards before market distribution. The QP is responsible for verifying that each batch meets its approved specifications, reviewing manufacturing and quality control documentation, and confirming adherence to Good Manufacturing Practices (GMP). Your understanding of QP release highlights its essential role in safeguarding drug quality and patient safety.

Regulatory Framework: Batch Release vs QP Release

The regulatory framework for batch release mandates thorough testing and documentation to ensure product compliance with safety and quality standards before market entry. Qualified Person (QP) release involves a legally designated individual responsible for certifying that each pharmaceutical batch meets all regulatory requirements and is fit for distribution. Your commitment to adhering to these regulatory processes ensures consistent product integrity and patient safety.

Role of the Qualified Person (QP) in Pharmaceutical Manufacturing

The Qualified Person (QP) is legally responsible for certifying that each pharmaceutical batch complies with all regulatory standards before release, ensuring patient safety and product efficacy. Batch release involves comprehensive review and verification of production records, quality control results, and compliance documentation, while QP release specifically authorizes the final distribution. Your understanding of the QP's critical role highlights the rigorous quality assurance embedded in pharmaceutical manufacturing processes.

Critical Differences Between Batch Release and QP Release

Batch release involves the overall authorization of a product batch for distribution after verifying compliance with production and quality standards, whereas QP release specifically refers to the Qualified Person's legal certification confirming the batch meets all regulatory requirements. The QP release is a mandatory regulatory step within the batch release process that ensures the product's safety, efficacy, and quality before it reaches the market. Understanding this distinction helps you navigate pharmaceutical compliance and quality assurance efficiently.

Documentation Requirements for Batch and QP Release

Batch release documentation must include complete production records, quality control test results, and compliance certificates to ensure the batch meets all regulatory standards. QP release documentation specifically requires a Qualified Person to review and verify that manufacturing and testing data comply with Good Manufacturing Practices before authorization for market release. Your thorough understanding of these documentation requirements ensures regulatory compliance and product quality throughout the release process.

Quality Assurance in Batch Release and QP Release

Quality Assurance in batch release involves thorough documentation review, analytical testing, and verification that the manufactured batch meets predefined specifications to ensure product consistency and safety. QP release by the Qualified Person includes a formal assessment of all production and quality data, compliance with regulatory standards, and certification that the batch is fit for market distribution. Both processes are critical in pharmaceutical manufacturing to maintain product integrity and patient safety.

Common Challenges in Batch and QP Release Processes

Batch release and QP release processes often face common challenges such as ensuring regulatory compliance, managing documentation accuracy, and maintaining consistent quality control standards. Delays can occur due to incomplete data review or discrepancies between batch records and product specifications, impacting your overall production timeline. Effective communication between quality teams and manufacturing is crucial to mitigate risks and streamline these release stages.

Compliance Risks: Batch Release Versus QP Release

Compliance risks in batch release arise from incomplete documentation, inadequate testing, or deviations not fully addressed before product distribution. QP release involves a Qualified Person who ensures all regulatory requirements and quality standards are met, significantly reducing the risk of non-compliance and potential market recalls. Your manufacturing process benefits from QP release by providing an additional layer of oversight that upholds compliance and product safety.

Best Practices for Efficient Batch and QP Release

Efficient batch release relies on thorough documentation review and adherence to GMP guidelines to ensure product quality before distribution, while QP release demands a qualified person's independent verification of compliance with regulatory standards. Best practices include implementing automated tracking systems for real-time batch data monitoring and maintaining clear communication between production, quality assurance, and QP teams to prevent delays. Leveraging risk-based approaches and continuous training for QPs minimizes errors and accelerates release timelines, optimizing overall supply chain efficiency.

Batch release vs QP release Infographic

libmatt.com

libmatt.com