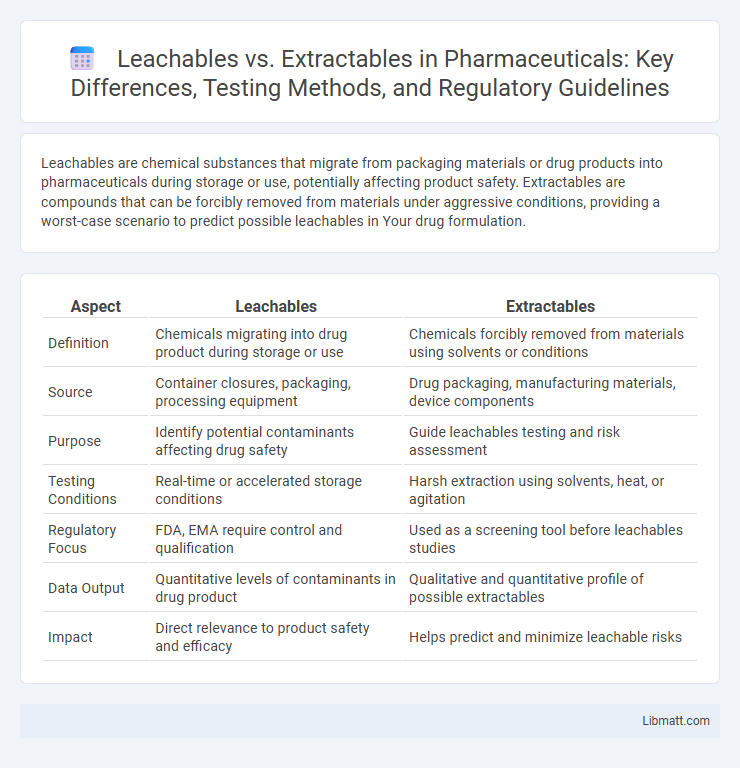

Leachables are chemical substances that migrate from packaging materials or drug products into pharmaceuticals during storage or use, potentially affecting product safety. Extractables are compounds that can be forcibly removed from materials under aggressive conditions, providing a worst-case scenario to predict possible leachables in Your drug formulation.

Table of Comparison

| Aspect | Leachables | Extractables |

|---|---|---|

| Definition | Chemicals migrating into drug product during storage or use | Chemicals forcibly removed from materials using solvents or conditions |

| Source | Container closures, packaging, processing equipment | Drug packaging, manufacturing materials, device components |

| Purpose | Identify potential contaminants affecting drug safety | Guide leachables testing and risk assessment |

| Testing Conditions | Real-time or accelerated storage conditions | Harsh extraction using solvents, heat, or agitation |

| Regulatory Focus | FDA, EMA require control and qualification | Used as a screening tool before leachables studies |

| Data Output | Quantitative levels of contaminants in drug product | Qualitative and quantitative profile of possible extractables |

| Impact | Direct relevance to product safety and efficacy | Helps predict and minimize leachable risks |

Introduction to Leachables and Extractables

Leachables and extractables are chemical compounds that migrate from packaging materials or manufacturing components into pharmaceutical products, potentially impacting safety and efficacy. Extractables are substances that can be forcibly removed under aggressive laboratory conditions, while leachables are compounds that actually migrate into the drug product under normal storage or use conditions. Understanding your product's specific leachables and extractables profile is essential for risk assessment and regulatory compliance in drug development.

Definitions: What Are Leachables and Extractables?

Leachables are chemical compounds that migrate from packaging or manufacturing materials into a drug product during storage or use, potentially impacting its safety and efficacy. Extractables are substances that can be forcibly removed from materials under specific laboratory conditions, providing a profile of possible contaminants. Understanding the distinct definitions of leachables and extractables is crucial for your pharmaceutical quality control and risk assessment processes.

Key Differences Between Leachables and Extractables

Leachables are chemical compounds that migrate into a product from its packaging or manufacturing process under normal storage conditions, while extractables are chemicals that can be forcibly removed using aggressive solvents or laboratory techniques. The key difference lies in their relevance to product safety: leachables pose direct risks during product use, whereas extractables help predict potential leachables by identifying all possible contaminants. Understanding these distinctions helps you ensure comprehensive risk assessments for pharmaceutical and medical device safety evaluations.

Importance in Pharmaceutical and Medical Devices

Leachables and extractables are critical in pharmaceutical and medical device industries because they can impact product safety, efficacy, and regulatory compliance. Extractables are chemical compounds that can be drawn out under aggressive conditions, while leachables migrate into the drug product under normal storage or use. Understanding these substances helps you mitigate contamination risks, ensuring patient safety and maintaining the integrity of drug-device combination products.

Sources of Leachables and Extractables

Sources of extractables include packaging materials, manufacturing equipment, and storage containers that release chemical compounds during processes involving solvents, heat, or mechanical stress. Leachables originate from these extractables when they migrate into the drug product under normal storage or use conditions, potentially affecting product safety and efficacy. Understanding your product's interaction with these materials helps in identifying and controlling risks associated with leachables and extractables.

Analytical Methods for Detection

Analytical methods for detecting leachables versus extractables primarily involve advanced techniques such as Gas Chromatography-Mass Spectrometry (GC-MS) and Liquid Chromatography-Mass Spectrometry (LC-MS), which provide high sensitivity and specificity for identifying chemical compounds. Headspace GC-MS is often utilized for volatile extractables, whereas non-volatile leachables are typically analyzed using LC-MS or High-Performance Liquid Chromatography (HPLC) coupled with Diode Array Detection (DAD). Method validation ensures accuracy, reproducibility, and limits of detection meet regulatory guidelines for pharmaceutical packaging and medical device safety assessments.

Regulatory Guidelines and Compliance

Regulatory guidelines for leachables and extractables emphasize rigorous testing to ensure product safety and compliance with agencies such as the FDA, EMA, and USP. Understanding the distinction between extractables--compounds that can be released under aggressive conditions--and leachables--substances migrating under normal usage--is critical for meeting these regulations. Your product development must incorporate thorough risk assessments and validated analytical methods to comply with global standards and avoid regulatory setbacks.

Impact on Product Safety and Quality

Leachables and extractables critically impact product safety and quality by introducing potentially harmful chemical compounds into pharmaceutical formulations or medical devices. Extractables are compounds that can be forcibly removed from materials under aggressive conditions, while leachables migrate into the product during normal use, posing direct risks to patient health. Understanding and controlling these substances ensures your product remains safe, stable, and compliant with regulatory standards.

Challenges in Testing and Risk Assessment

Testing leachables and extractables involves complex analytical challenges due to the diverse chemical nature of potential contaminants and their low concentration levels in pharmaceutical products. Accurate risk assessment requires advanced techniques such as high-resolution mass spectrometry and comprehensive sample preparation to detect, identify, and quantify these compounds. Understanding these challenges is crucial for ensuring Your product's safety and compliance with regulatory standards.

Best Practices for Managing Leachables and Extractables

Effective management of leachables and extractables requires rigorous analytical testing methods such as gas chromatography-mass spectrometry (GC-MS) and liquid chromatography-mass spectrometry (LC-MS) to identify potential contaminants in packaging and drug products. Implementing material qualification processes and comprehensive risk assessments ensures compatibility and minimizes contamination risks throughout the product lifecycle. Establishing strict regulatory compliance protocols aligned with FDA and ICH guidelines enhances product safety and quality control.

Leachables vs Extractables Infographic

libmatt.com

libmatt.com