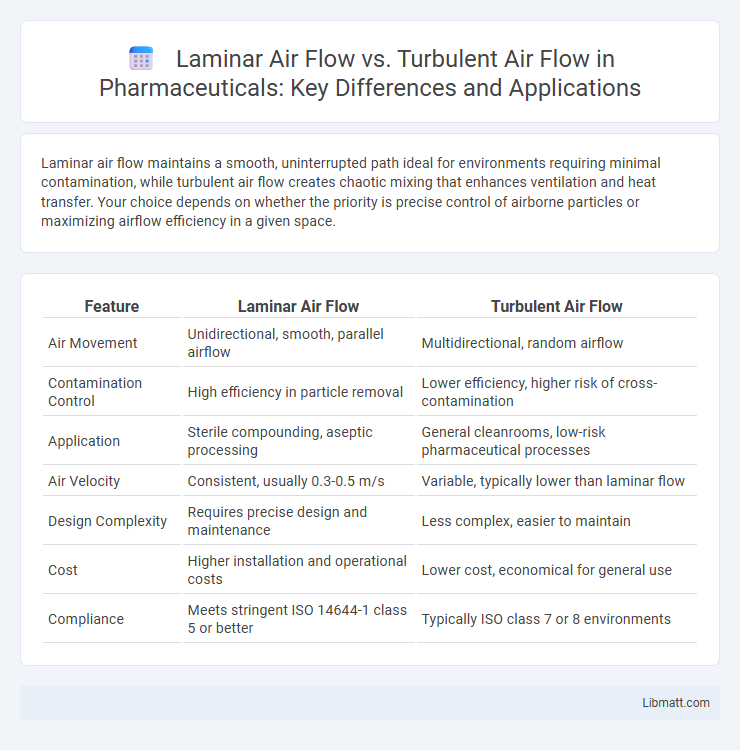

Laminar air flow maintains a smooth, uninterrupted path ideal for environments requiring minimal contamination, while turbulent air flow creates chaotic mixing that enhances ventilation and heat transfer. Your choice depends on whether the priority is precise control of airborne particles or maximizing airflow efficiency in a given space.

Table of Comparison

| Feature | Laminar Air Flow | Turbulent Air Flow |

|---|---|---|

| Air Movement | Unidirectional, smooth, parallel airflow | Multidirectional, random airflow |

| Contamination Control | High efficiency in particle removal | Lower efficiency, higher risk of cross-contamination |

| Application | Sterile compounding, aseptic processing | General cleanrooms, low-risk pharmaceutical processes |

| Air Velocity | Consistent, usually 0.3-0.5 m/s | Variable, typically lower than laminar flow |

| Design Complexity | Requires precise design and maintenance | Less complex, easier to maintain |

| Cost | Higher installation and operational costs | Lower cost, economical for general use |

| Compliance | Meets stringent ISO 14644-1 class 5 or better | Typically ISO class 7 or 8 environments |

Introduction to Air Flow Principles

Laminar air flow is characterized by smooth, parallel layers of air moving at consistent velocities, minimizing mixing and disturbances. Turbulent air flow exhibits chaotic and irregular movements, enhancing mixing and heat transfer through its swirling eddies. Understanding these principles is crucial for applications in aerodynamics, HVAC systems, and cleanroom environments to optimize performance and control contamination.

Defining Laminar Air Flow

Laminar air flow refers to a smooth, consistent airflow in which air moves in parallel layers with minimal disruption between them, ensuring low turbulence and uniform velocity throughout the space. This type of airflow is essential in environments requiring contamination control, such as cleanrooms and laboratories, as it helps prevent particulate matter from mixing or settling on surfaces. Understanding laminar air flow can help you optimize air quality and maintain sterile conditions critical for sensitive processes.

Understanding Turbulent Air Flow

Turbulent air flow is characterized by chaotic, irregular fluid movement with eddies and vortices, resulting in enhanced mixing and heat transfer compared to laminar flow. It typically occurs at higher velocities or Reynolds numbers above 4000, where inertial forces dominate over viscous forces. Understanding turbulent air flow is crucial for optimizing ventilation, pollutant dispersion, and aerodynamic performance in engineering applications.

Key Differences: Laminar vs Turbulent Air Flow

Laminar air flow features smooth, parallel layers of airflow with minimal mixing and low velocity, ensuring a controlled environment ideal for cleanrooms and laboratories. Turbulent air flow is characterized by chaotic, irregular fluid motion with high mixing and fluctuating velocities, commonly seen in natural ventilation and industrial applications. The key differences lie in the flow patterns, velocity profiles, and the degree of mixing, impacting air quality control and particle dispersion.

Factors Influencing Air Flow Patterns

Air flow patterns between laminar and turbulent flow are primarily influenced by factors such as air velocity, surface roughness, and the Reynolds number, which quantifies the ratio of inertial forces to viscous forces in the fluid. Smooth surfaces and lower velocities promote laminar flow by minimizing disturbances, while higher velocities and surface irregularities increase turbulence due to chaotic and irregular fluid motion. Temperature gradients and pressure differences also affect flow stability, further determining whether the air maintains a streamlined path or shifts to turbulent behavior.

Applications of Laminar Air Flow

Laminar air flow creates a uniform, unidirectional airflow that minimizes particle contamination, making it essential in cleanroom environments, pharmaceutical manufacturing, and semiconductor fabrication. Its controlled, smooth airflow is critical for maintaining sterile conditions in hospitals and laboratories when working with sensitive biological samples. The precise air movement in laminar flow hoods ensures product integrity and safety in industries requiring contamination-free environments.

Applications of Turbulent Air Flow

Turbulent air flow is widely used in industrial mixing, combustion processes, and HVAC systems where enhanced heat and mass transfer are essential. Your facility can benefit from turbulent flow in applications such as chemical reactors, exhaust systems, and ventilation, where efficient mixing and rapid dispersion of particles improve performance. This type of airflow facilitates thorough blending and prevents stagnation, making it crucial for processes requiring high reaction rates and uniform conditions.

Advantages and Disadvantages of Each Flow Type

Laminar air flow offers the advantage of smooth, consistent airflow that minimizes contamination and is ideal for cleanrooms and sensitive manufacturing processes, but it can be less effective in mixing and dispersing particles. Turbulent air flow excels at thorough mixing and rapid particle dispersion, which enhances ventilation and dilution of contaminants, though it may increase the risk of spreading airborne particles. Choosing between laminar and turbulent air flow depends on your need for contamination control versus efficient air mixing in the specific environment.

Performance Impacts in Controlled Environments

Laminar air flow provides a uniform, unidirectional airflow that minimizes particle contamination and enhances sterility in controlled environments such as cleanrooms and laboratories. Turbulent air flow increases mixing and dilution of airborne contaminants but may lead to greater variability in particle distribution and potential contamination risks. Optimizing the balance between laminar and turbulent flows is crucial for maintaining strict environmental standards while ensuring efficient air exchange and contaminant removal.

Choosing the Right Air Flow System

Choosing the right air flow system depends on your specific application requirements, with laminar air flow providing a smooth, unidirectional stream ideal for environments needing contamination control, such as cleanrooms and laboratories. Turbulent air flow, characterized by mixed and chaotic air movement, is suited for applications requiring rapid dispersion and temperature uniformity, like HVAC systems in residential or commercial buildings. Understanding the benefits and limitations of each system ensures your choice optimizes air quality, safety, and efficiency.

Laminar Air Flow vs Turbulent Air Flow Infographic

libmatt.com

libmatt.com