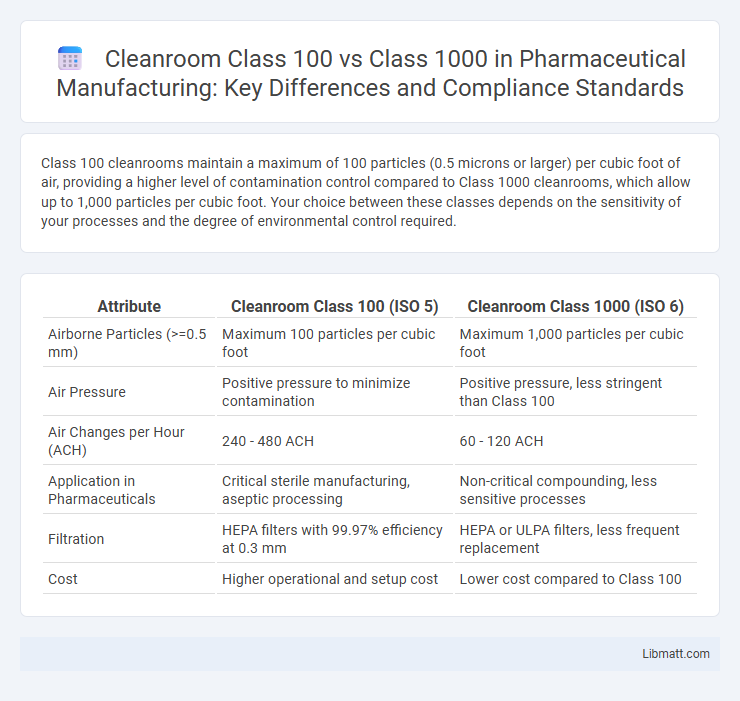

Class 100 cleanrooms maintain a maximum of 100 particles (0.5 microns or larger) per cubic foot of air, providing a higher level of contamination control compared to Class 1000 cleanrooms, which allow up to 1,000 particles per cubic foot. Your choice between these classes depends on the sensitivity of your processes and the degree of environmental control required.

Table of Comparison

| Attribute | Cleanroom Class 100 (ISO 5) | Cleanroom Class 1000 (ISO 6) |

|---|---|---|

| Airborne Particles (>=0.5 mm) | Maximum 100 particles per cubic foot | Maximum 1,000 particles per cubic foot |

| Air Pressure | Positive pressure to minimize contamination | Positive pressure, less stringent than Class 100 |

| Air Changes per Hour (ACH) | 240 - 480 ACH | 60 - 120 ACH |

| Application in Pharmaceuticals | Critical sterile manufacturing, aseptic processing | Non-critical compounding, less sensitive processes |

| Filtration | HEPA filters with 99.97% efficiency at 0.3 mm | HEPA or ULPA filters, less frequent replacement |

| Cost | Higher operational and setup cost | Lower cost compared to Class 100 |

Introduction to Cleanroom Classifications

Cleanroom Class 100 and Class 1000 represent specific classifications based on the maximum allowable particle count per cubic foot of air, with Class 100 permitting up to 100 particles and Class 1000 allowing up to 1,000 particles sized 0.5 microns or larger. These classifications ensure stringent contamination control, essential for industries such as pharmaceuticals, semiconductor manufacturing, and aerospace, where maintaining air purity can impact product quality and safety. Understanding these classes helps you select the appropriate cleanroom environment tailored to your contamination control requirements.

Understanding Cleanroom Class 100

Cleanroom Class 100, also known as ISO Class 5, maintains a maximum of 100 particles measuring 0.5 microns or larger per cubic foot of air, ensuring exceptionally low contamination levels. Compared to Class 1000, which allows up to 1,000 such particles, Class 100 provides a more stringent controlled environment essential for sensitive manufacturing like semiconductor fabrication and pharmaceutical production. Your operations demanding ultra-clean conditions benefit significantly from the superior air filtration and strict protocols defining Cleanroom Class 100 standards.

Overview of Cleanroom Class 1000

Cleanroom Class 1000 maintains an environment with no more than 1,000 particles larger than 0.5 microns per cubic foot of air, supporting industries like pharmaceuticals and electronics where controlled contamination is critical. This class allows for a higher particle count compared to Class 100, which restricts particles to 100 per cubic foot, making Class 1000 more cost-effective for processes with moderate cleanliness requirements. Your operations benefit from understanding these distinctions to select a cleanroom that balances contamination control with budget and process needs.

Key Differences: Class 100 vs Class 1000

Cleanroom Class 100, also known as ISO 5, allows a maximum of 100 particles (0.5 microns or larger) per cubic foot of air, while Class 1000, or ISO 6, permits up to 1,000 such particles, making Class 100 significantly cleaner. The stringent air filtration and pressure controls in Class 100 environments support industries like semiconductor manufacturing, where contamination sensitivity is critical, whereas Class 1000 suits processes with less rigorous cleanliness demands. Understanding these key differences helps you select the appropriate cleanroom classification to meet your contamination control requirements efficiently.

Air Filtration Standards and Particle Counts

Cleanroom Class 100 maintains air cleanliness with a maximum of 100 particles sized 0.5 microns or larger per cubic foot, adhering to the stringent Federal Standard 209E. In contrast, Class 1000 allows up to 1,000 particles of the same size, permitting a tenfold increase in particle concentration. Both classes rely on High Efficiency Particulate Air (HEPA) filters, but Class 100 requires more rigorous filtration efficiency and airflow control to achieve lower particle counts essential for sensitive manufacturing processes.

Applications of Class 100 Cleanrooms

Class 100 cleanrooms maintain fewer than 100 particles per cubic foot, making them essential for industries requiring extremely low contamination levels, such as semiconductor manufacturing, pharmaceutical production, and aerospace component assembly. These cleanrooms provide a highly controlled environment that safeguards sensitive processes and enhances product quality. Your operations benefit from the superior particulate control, ensuring compliance with strict industry standards and reducing the risk of defects.

Applications of Class 1000 Cleanrooms

Class 1000 cleanrooms, maintaining a maximum of 1,000 particles per cubic foot of 0.5 microns or larger, are widely used in industries such as pharmaceutical manufacturing, medical device production, and electronics assembly where moderate contamination control is critical. These cleanrooms support processes that require a controlled environment to prevent product contamination but do not demand the ultra-stringent conditions of Class 100 cleanrooms. Applications include sterile compounding, semiconductor wafer fabrication, and packaging of sterile products where particulate and microbial control at this level ensures product quality and regulatory compliance.

Construction and Design Considerations

Cleanroom Class 100 features more stringent construction and design standards than Class 1000 to minimize particle contamination, including smoother surfaces, fewer seams, and specialized materials that resist particle generation. HVAC systems in Class 100 cleanrooms have higher filtration efficiency with HEPA filters that remove 99.97% of particles 0.3 microns and larger, ensuring ultra-clean air flow patterns. Your cleanroom's design must carefully control airflow velocity, pressure differentials, and material compatibility to meet the specific cleanliness requirements of Class 100 environments compared to the more lenient Class 1000.

Cost Comparison: Maintenance and Operation

Cleanroom Class 100 environments require significantly higher maintenance and operational costs compared to Class 1000 due to stricter air filtration standards, necessitating more frequent HEPA filter replacements and rigorous monitoring systems. The increased energy consumption for maintaining Class 100's ultra-low particle levels results in elevated utility expenses and specialized labor for continuous cleanliness verification. In contrast, Class 1000 cleanrooms, while still demanding careful upkeep, offer reduced operational complexity and lower maintenance frequency, making them more cost-effective for less contamination-sensitive manufacturing processes.

Selecting the Right Cleanroom for Your Needs

Choosing between Cleanroom Class 100 and Class 1000 depends on the level of particulate control required for your application, with Class 100 maintaining no more than 100 particles (0.5 microns or larger) per cubic foot, while Class 1000 allows up to 1,000 particles. Your selection should consider the sensitivity of your process to contamination, as Class 100 cleanrooms are essential for industries like semiconductor manufacturing and pharmaceuticals where ultra-clean environments are critical. Factoring in operational costs and maintenance complexity is vital, since Class 100 cleanrooms demand more stringent controls and higher expenses compared to Class 1000 setups.

Cleanroom Class 100 vs Class 1000 Infographic

libmatt.com

libmatt.com