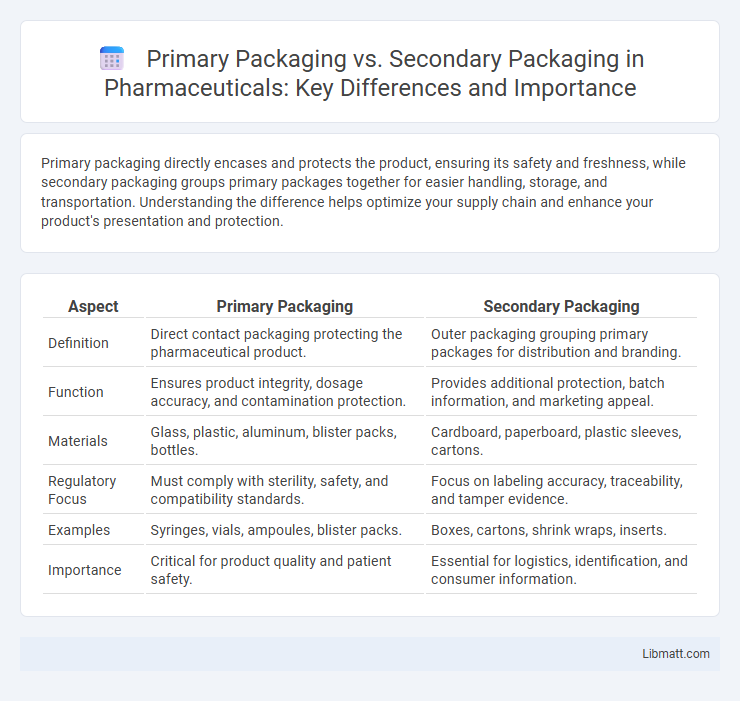

Primary packaging directly encases and protects the product, ensuring its safety and freshness, while secondary packaging groups primary packages together for easier handling, storage, and transportation. Understanding the difference helps optimize your supply chain and enhance your product's presentation and protection.

Table of Comparison

| Aspect | Primary Packaging | Secondary Packaging |

|---|---|---|

| Definition | Direct contact packaging protecting the pharmaceutical product. | Outer packaging grouping primary packages for distribution and branding. |

| Function | Ensures product integrity, dosage accuracy, and contamination protection. | Provides additional protection, batch information, and marketing appeal. |

| Materials | Glass, plastic, aluminum, blister packs, bottles. | Cardboard, paperboard, plastic sleeves, cartons. |

| Regulatory Focus | Must comply with sterility, safety, and compatibility standards. | Focus on labeling accuracy, traceability, and tamper evidence. |

| Examples | Syringes, vials, ampoules, blister packs. | Boxes, cartons, shrink wraps, inserts. |

| Importance | Critical for product quality and patient safety. | Essential for logistics, identification, and consumer information. |

Introduction to Packaging Types

Primary packaging directly encloses and protects the product, ensuring safety and maintaining quality from production to consumption. Secondary packaging groups multiple primary packages for easier handling, storage, and transportation, often providing branding and informational details. Understanding the distinction between primary and secondary packaging helps you optimize product presentation and logistics efficiency.

What is Primary Packaging?

Primary packaging refers to the immediate container or wrapping that holds and protects a product directly, ensuring its safety, freshness, and usability. Common examples include bottles, blister packs, cans, and jars designed to preserve the product's integrity and provide essential information like labels and barcodes. This packaging is crucial for maintaining product quality, preventing contamination, and facilitating consumption or use by the end consumer.

Key Functions of Primary Packaging

Primary packaging serves as the immediate container for a product, providing protection from contamination, damage, and spoilage while maintaining product integrity. It plays a critical role in preserving freshness, ensuring safety, and enabling convenient usage or consumption. Your choice of primary packaging directly impacts product shelf life, consumer experience, and regulatory compliance.

What is Secondary Packaging?

Secondary packaging is the outer layer that groups primary packaged products for easier handling, transportation, and storage. It provides additional protection, branding, and information, helping streamline distribution and retail display. Understanding secondary packaging allows you to optimize logistics and enhance product presentation.

Key Functions of Secondary Packaging

Secondary packaging primarily serves to protect primary packaging during transportation and storage by providing an additional barrier against physical damage, contamination, and environmental factors. It facilitates efficient handling, stacking, and distribution through standardized shapes and sizes, enhancing logistical efficiency and reducing costs. Secondary packaging also plays a crucial role in marketing and information dissemination by displaying branding, product information, and regulatory labeling to consumers and retailers.

Primary vs Secondary Packaging: Core Differences

Primary packaging directly encloses and protects the product, ensuring its safety, freshness, and usability while often serving as the first point of consumer interaction. Secondary packaging groups primary packages together for easier handling, storage, and transportation, providing additional protection and branding opportunities without direct contact with the product. Understanding these core differences helps you optimize packaging strategy for product integrity and supply chain efficiency.

Materials Used in Primary and Secondary Packaging

Primary packaging commonly utilizes materials such as polyethylene terephthalate (PET), glass, aluminum, and flexible films to ensure direct contact safety and protection of the product. Secondary packaging often involves corrugated cardboard, paperboard, shrink wrap, and molded pulp designed for additional protection, branding, and ease of handling during transportation. The selection of materials in both packaging levels prioritizes durability, sustainability, and regulatory compliance specific to the product type and supply chain requirements.

Role in Product Protection and Safety

Primary packaging directly encloses the product, providing the first line of defense against contamination, damage, and tampering to ensure product safety and integrity. Secondary packaging offers additional protection during transportation, storage, and handling by bundling primary packages together and safeguarding them from physical impacts, environmental factors, and theft. Both packaging levels are crucial for maintaining product quality throughout the supply chain and complying with regulatory standards.

Impact on Branding and Consumer Experience

Primary packaging directly influences Your brand perception by serving as the first point of interaction with consumers, showcasing product quality and design. Secondary packaging enhances the overall consumer experience by providing additional information, protection, and convenience while reinforcing brand messaging through cohesive visual elements. Effective coordination between primary and secondary packaging maximizes brand recognition and fosters customer loyalty.

Choosing the Right Packaging for Your Product

Choosing the right packaging for your product involves understanding the distinct functions of primary and secondary packaging. Primary packaging directly contacts the product, ensuring protection, preservation, and convenience for the consumer, making it essential for perishable goods like food and pharmaceuticals. Secondary packaging groups primary packages for efficient handling, transport, and branding, which is critical for bulk distribution and retail presentation.

Primary Packaging vs Secondary Packaging Infographic

libmatt.com

libmatt.com