Horizontal laminar flow directs clean air across the workspace from one side to the other, effectively protecting products from contamination by airborne particles entering the area. Your choice between horizontal and vertical laminar flow depends on the specific application, as vertical laminar flow pushes sterile air downward, creating a clean zone by displacing particles away from critical surfaces or processes.

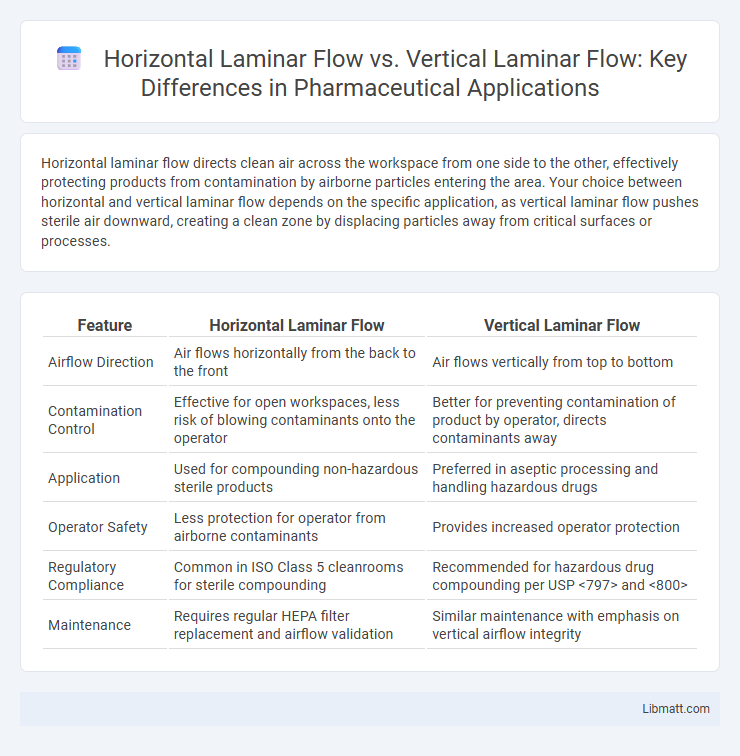

Table of Comparison

| Feature | Horizontal Laminar Flow | Vertical Laminar Flow |

|---|---|---|

| Airflow Direction | Air flows horizontally from the back to the front | Air flows vertically from top to bottom |

| Contamination Control | Effective for open workspaces, less risk of blowing contaminants onto the operator | Better for preventing contamination of product by operator, directs contaminants away |

| Application | Used for compounding non-hazardous sterile products | Preferred in aseptic processing and handling hazardous drugs |

| Operator Safety | Less protection for operator from airborne contaminants | Provides increased operator protection |

| Regulatory Compliance | Common in ISO Class 5 cleanrooms for sterile compounding | Recommended for hazardous drug compounding per USP <797> and <800> |

| Maintenance | Requires regular HEPA filter replacement and airflow validation | Similar maintenance with emphasis on vertical airflow integrity |

Introduction to Laminar Flow Systems

Laminar flow systems create a contamination-free environment by directing filtered air in a smooth, unidirectional flow. Horizontal laminar flow pushes air from the back of the unit toward the user, reducing contamination risk outside the workspace but potentially exposing the operator. Vertical laminar flow moves air from the top downward, protecting both the user and the product by directing contaminants away from the critical work area.

What Is Horizontal Laminar Flow?

Horizontal laminar flow refers to the controlled movement of air in a smooth, unidirectional horizontal stream, typically used in cleanroom environments and laboratories to minimize contamination. This system draws air through HEPA filters and directs it horizontally across the work surface, effectively pushing away airborne particles and contaminants from sensitive materials. Horizontal laminar flow units are preferred for processes where maintaining a sterile environment on a flat work area is critical, such as in pharmaceutical manufacturing and microbiology labs.

What Is Vertical Laminar Flow?

Vertical Laminar Flow refers to a clean airflow system where filtered air moves vertically from the ceiling down to the work surface, minimizing contamination by pushing particles away from the user and sensitive materials. This type of flow is essential in environments like laboratories and cleanrooms where maintaining sterile conditions is critical for processes such as microbiological research or pharmaceutical compounding. Your workspace benefits from vertical laminar flow by ensuring consistent, particle-free air coverage, protecting both samples and operators from airborne contaminants.

Core Differences Between Horizontal and Vertical Laminar Flow

Horizontal laminar flow directs clean air from the back of the unit towards the user, creating a protective airflow barrier ideal for supporting activities sensitive to contamination. Vertical laminar flow pushes filtered air downward, minimizing particle contamination by preventing airborne contaminants from settling into the work area. Your choice between horizontal and vertical laminar flow depends on the specific contamination control needs and workspace layout to ensure optimal environmental protection.

Airflow Direction and Contamination Control

Horizontal laminar flow systems direct clean air horizontally across the workspace, effectively protecting the product from contamination by sweeping airborne particles away from critical areas. Vertical laminar flow units push air downward in a vertical direction, creating a clean air barrier that prevents contaminants from entering the work zone and is especially useful in minimizing cross-contamination. Your choice between horizontal and vertical laminar flow depends on specific contamination control needs and the nature of the work being performed.

Applications of Horizontal Laminar Flow Cabinets

Horizontal laminar flow cabinets are widely used in applications requiring a sterile environment with minimal contamination risk, such as tissue culture, pharmaceutical compounding, and electronic component assembly. These cabinets direct filtered airflow horizontally across the work surface, protecting the product but not the user, making them ideal for non-hazardous materials. Your laboratory or manufacturing process benefits from horizontal laminar flow cabinets when consistent, particle-free air is essential to product integrity.

Applications of Vertical Laminar Flow Cabinets

Vertical laminar flow cabinets are primarily utilized in pharmaceutical manufacturing, tissue culture laboratories, and electronic component assembly due to their ability to provide aseptic conditions by directing filtered air downwards onto the work surface. These cabinets ensure contamination control in processes requiring sterile environments, such as microbiology, clinical diagnostics, and semiconductor production. Vertical airflow minimizes cross-contamination risks, making them essential for applications demanding high levels of cleanliness and product integrity.

Advantages of Horizontal Laminar Flow

Horizontal laminar flow offers superior protection for personnel and products by directing airflow away from the operator, minimizing contamination risks. Its design facilitates easier maintenance and cleaning due to accessible work surfaces and straightforward airflow patterns. You benefit from enhanced safety and efficiency, especially in applications requiring sterile environments such as pharmaceutical manufacturing and laboratory work.

Advantages of Vertical Laminar Flow

Vertical laminar flow cabinets offer superior protection against contamination by directing airflow downward onto the workspace, reducing the risk of particles falling into sterile samples. This configuration minimizes cross-contamination and is especially beneficial in pharmaceutical, biomedical, and microelectronics environments. Enhanced operator safety and compliance with stringent cleanroom standards are key advantages, making vertical laminar flow ideal for handling sensitive materials.

Choosing the Right Laminar Flow System for Your Needs

Selecting between horizontal laminar flow and vertical laminar flow systems depends on the specific application requirements, such as contamination control level and workspace size. Horizontal laminar flow systems direct air horizontally across the workspace, ideal for small-scale tasks requiring minimal particle disruption, while vertical laminar flow systems push air downward, providing superior sterile environments suitable for laboratory and medical settings. Evaluating factors like airflow pattern, particle contamination risks, and space configuration ensures the optimal laminar flow system choice for maintaining product integrity and safety.

Horizontal Laminar Flow vs Vertical Laminar Flow Infographic

libmatt.com

libmatt.com