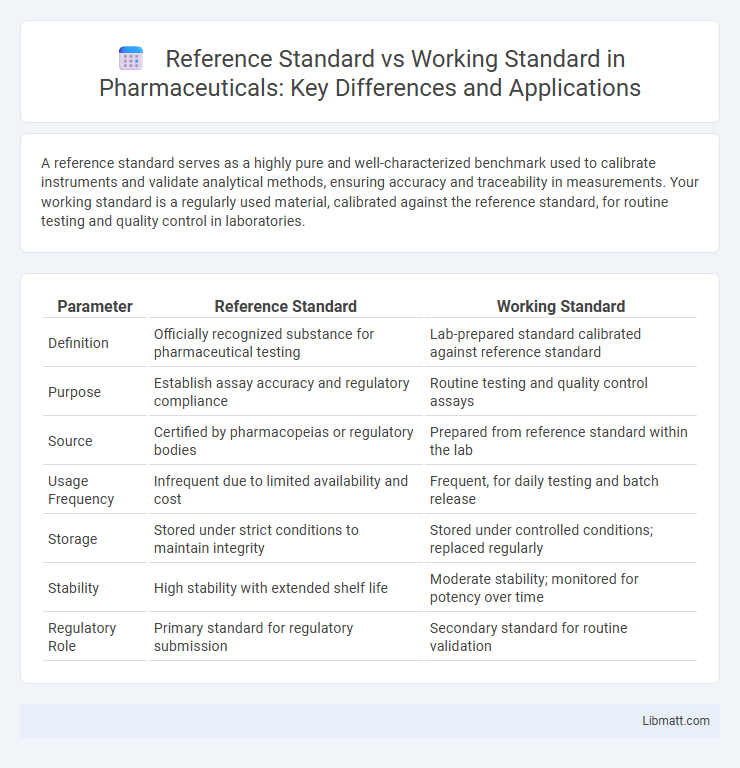

A reference standard serves as a highly pure and well-characterized benchmark used to calibrate instruments and validate analytical methods, ensuring accuracy and traceability in measurements. Your working standard is a regularly used material, calibrated against the reference standard, for routine testing and quality control in laboratories.

Table of Comparison

| Parameter | Reference Standard | Working Standard |

|---|---|---|

| Definition | Officially recognized substance for pharmaceutical testing | Lab-prepared standard calibrated against reference standard |

| Purpose | Establish assay accuracy and regulatory compliance | Routine testing and quality control assays |

| Source | Certified by pharmacopeias or regulatory bodies | Prepared from reference standard within the lab |

| Usage Frequency | Infrequent due to limited availability and cost | Frequent, for daily testing and batch release |

| Storage | Stored under strict conditions to maintain integrity | Stored under controlled conditions; replaced regularly |

| Stability | High stability with extended shelf life | Moderate stability; monitored for potency over time |

| Regulatory Role | Primary standard for regulatory submission | Secondary standard for routine validation |

Introduction to Reference Standards and Working Standards

Reference standards are highly characterized, stable materials used to calibrate instruments, validate methods, and ensure consistency in analytical testing. Working standards are secondary samples calibrated against reference standards, providing routine quality control during manufacturing and testing processes. Your laboratory relies on the accuracy of both standards to maintain compliance with regulatory requirements and ensure reliable results.

Definitions: Reference Standard vs Working Standard

Reference standards are highly purified substances or materials used as benchmarks to calibrate instruments and validate analytical methods, ensuring accuracy and consistency in measurements. Working standards are secondary materials calibrated against reference standards to control routine quality checks and maintain daily operational reliability. Your laboratory relies on reference standards for precision calibration, while working standards facilitate efficient, ongoing quality control processes.

Key Differences Between Reference and Working Standards

Reference standards serve as highly pure, accurately characterized materials used to calibrate and validate analytical methods, ensuring traceability to international standards. Working standards are routinely used in testing laboratories for daily quality control and may have slightly less stringent purity but are calibrated periodically against reference standards. Understanding these distinctions helps maintain precision in Your analytical measurements and regulatory compliance.

Importance of Reference Standards in Quality Control

Reference standards serve as the benchmark in quality control, ensuring accuracy and consistency in testing procedures across laboratories. These highly characterized materials provide the definitive criteria against which working standards and test samples are measured, maintaining the integrity of analytical results. Your quality control processes rely on reference standards to guarantee compliance with regulatory requirements and product specifications.

Role of Working Standards in Routine Analysis

Working standards play a crucial role in routine analysis by serving as calibrated references to ensure accuracy and consistency in measurements. They are derived from highly characterized reference standards but are more practical for daily use due to their stability and cost-effectiveness. Regular comparison against reference standards maintains the integrity of working standards, enabling reliable quality control and validation in analytical processes.

Certification and Traceability of Standards

Reference standards undergo rigorous certification processes traceable to national or international measurement institutes, ensuring their high accuracy and reliability for calibrating other standards. Working standards, calibrated against these certified reference standards, maintain traceability within the measurement hierarchy but may have comparatively lower accuracy. Robust documentation and periodic recalibration guarantee the traceability and integrity of both standards throughout their lifecycle.

Preparation and Qualification of Working Standards

Working standards are meticulously prepared by diluting or aliquoting the reference standard to ensure consistent concentration and matrix similarity, maintaining stability under specified conditions. Qualification of working standards involves rigorous validation through potency assays, chromatographic profiling, and comparison against the reference standard to confirm accuracy, precision, and reproducibility. Proper documentation of preparation procedures, stability data, and analytical validation ensures regulatory compliance and reliable routine quality control testing.

Applications in Pharmaceutical and Analytical Laboratories

Reference standards serve as highly purified substances with known properties, crucial for calibrating instruments and validating methods in pharmaceutical and analytical laboratories. Working standards, derived from reference standards, are routinely used for quality control testing to ensure consistency and compliance during production. Your laboratory relies on this hierarchical system to maintain accuracy and regulatory adherence in drug formulation and analysis processes.

Regulatory Guidelines for Standards Usage

Regulatory guidelines for standards usage strictly differentiate between reference standards and working standards to ensure accuracy in analytical testing and calibration. Reference standards serve as the highest purity benchmarks validated by pharmacopoeias like USP or EP, while working standards are calibrated against these references for routine quality control purposes. Your compliance with these guidelines ensures traceability, reliability, and consistency in product testing across pharmaceutical and manufacturing industries.

Best Practices for Managing Reference and Working Standards

Effective management of reference and working standards involves regular verification of reference standards against national or international primary standards to ensure traceability and accuracy. Implementing a calibration schedule for working standards maintains their reliability and reduces measurement uncertainty in routine testing. Proper documentation and controlled storage conditions prevent contamination and degradation, supporting consistent quality assurance in laboratory environments.

Reference standard vs working standard Infographic

libmatt.com

libmatt.com