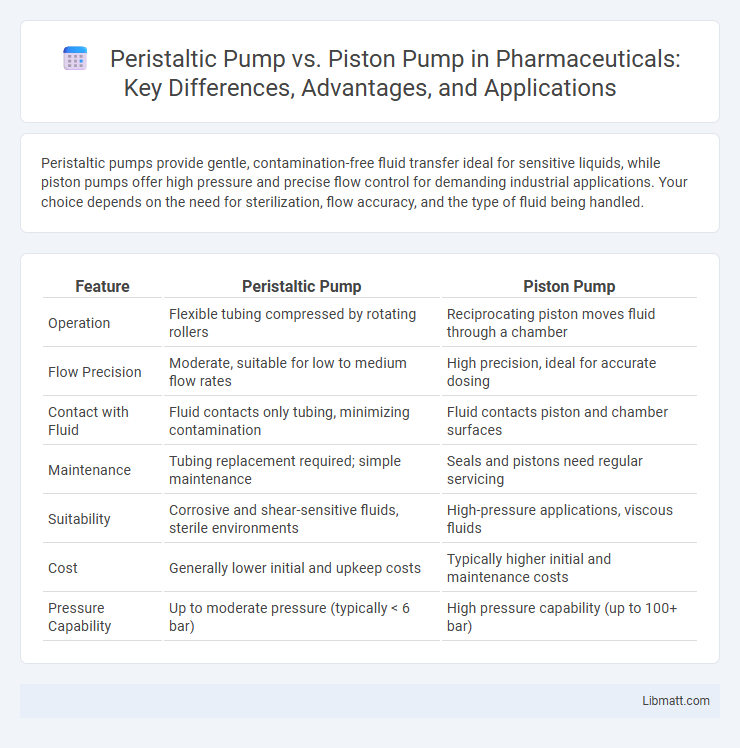

Peristaltic pumps provide gentle, contamination-free fluid transfer ideal for sensitive liquids, while piston pumps offer high pressure and precise flow control for demanding industrial applications. Your choice depends on the need for sterilization, flow accuracy, and the type of fluid being handled.

Table of Comparison

| Feature | Peristaltic Pump | Piston Pump |

|---|---|---|

| Operation | Flexible tubing compressed by rotating rollers | Reciprocating piston moves fluid through a chamber |

| Flow Precision | Moderate, suitable for low to medium flow rates | High precision, ideal for accurate dosing |

| Contact with Fluid | Fluid contacts only tubing, minimizing contamination | Fluid contacts piston and chamber surfaces |

| Maintenance | Tubing replacement required; simple maintenance | Seals and pistons need regular servicing |

| Suitability | Corrosive and shear-sensitive fluids, sterile environments | High-pressure applications, viscous fluids |

| Cost | Generally lower initial and upkeep costs | Typically higher initial and maintenance costs |

| Pressure Capability | Up to moderate pressure (typically < 6 bar) | High pressure capability (up to 100+ bar) |

Introduction to Peristaltic Pumps and Piston Pumps

Peristaltic pumps operate by compressing flexible tubing to move fluids, providing a contamination-free and gentle pumping action ideal for sensitive liquids. Piston pumps use a reciprocating piston to create pressure, offering high precision and the ability to handle viscous or abrasive fluids with consistent flow rates. Your choice between these pumps depends on application requirements such as fluid type, flow accuracy, and maintenance considerations.

Working Principles: Peristaltic vs Piston Pumps

Peristaltic pumps operate by compressing and releasing a flexible tube to create suction and move fluids in a continuous, smooth flow, ideal for handling corrosive or shear-sensitive liquids. Piston pumps function through the reciprocating motion of a piston within a cylinder, generating high pressure and precise fluid displacement suitable for high-viscosity or high-pressure applications. The key difference lies in peristaltic pumps offering contamination-free pumping with minimal maintenance, while piston pumps deliver consistent volumetric accuracy and robust pressure output.

Key Differences Between Peristaltic and Piston Pumps

Peristaltic pumps use flexible tubing and rollers to create a wave-like motion that moves fluid, providing gentle, contamination-free handling ideal for sterile or sensitive applications. Piston pumps rely on a reciprocating piston mechanism generating high pressure and precise flow control, making them suitable for demanding industrial uses requiring consistent output. Understanding these key differences helps you select the right pump based on fluid type, pressure needs, and maintenance preferences.

Applications: Where Peristaltic Pumps Excel

Peristaltic pumps excel in applications requiring sterile or contamination-free fluid transfer, such as in pharmaceuticals, biotechnology, and food processing industries. Their design ensures fluids only contact the tubing, making them ideal for handling aggressive chemicals, viscous fluids, and shear-sensitive materials without cross-contamination. You benefit from precise flow control and easy maintenance, especially in medical and laboratory settings where hygiene and accuracy are critical.

Applications: Where Piston Pumps Dominate

Piston pumps dominate in applications requiring high pressure and precise flow control, such as hydraulic systems, oil and gas extraction, and industrial forging processes. Their ability to handle viscous fluids and deliver consistent volumetric flow makes them ideal for fuel injection, chemical dosing, and high-pressure cleaning. These pumps excel in environments demanding durability and accuracy under extreme pressure conditions.

Precision and Accuracy Comparison

Peristaltic pumps offer high precision with consistent flow rates by minimizing fluid contact and reducing contamination risk, making them ideal for sterile or chemical-sensitive applications. Piston pumps excel in accuracy by delivering exact volumes through mechanical displacement, suitable for high-pressure or viscous fluid transfer where tight volumetric control is essential. Your choice depends on whether consistent precision or exact volumetric accuracy is more critical for your process requirements.

Maintenance Requirements and Longevity

Peristaltic pumps require minimal maintenance due to their simple design with no seals or valves that contact the fluid, reducing wear and contamination risks, making them ideal for handling abrasive or corrosive fluids. Piston pumps demand more frequent maintenance because of their complex seals and valves that experience high pressure and mechanical stress, leading to faster wear and the need for periodic replacement or repairs. Your choice depends on prioritizing either lower maintenance and longer service life with peristaltic pumps or higher pressure handling with piston pumps despite increased upkeep.

Fluid Compatibility and Contamination Risks

Peristaltic pumps offer superior fluid compatibility due to their tubing-based design, preventing direct contact between the fluid and pump components, which significantly reduces contamination risks, ideal for sterile or corrosive fluids. Piston pumps, while capable of handling higher pressures and viscous fluids, involve multiple moving parts in contact with the fluid, increasing the risk of contamination and requiring rigorous maintenance. Your choice depends on whether fluid purity or pressure capacity is the critical factor in your application.

Energy Efficiency and Operating Costs

Peristaltic pumps generally offer higher energy efficiency due to their simple design and reduced mechanical components, leading to lower operating costs and minimal maintenance requirements. Piston pumps, while capable of handling higher pressures, often consume more energy because of complex moving parts and frequent lubrication needs, increasing long-term expenses. Optimizing your system with a peristaltic pump can reduce energy consumption and maintenance costs, making it ideal for applications prioritizing cost-effectiveness and durability.

Choosing the Right Pump: Peristaltic vs Piston

Choosing the right pump depends on application requirements: peristaltic pumps are ideal for gentle, contamination-free fluid handling with shear-sensitive or abrasive liquids, while piston pumps excel in high-pressure, precise flow control scenarios. Peristaltic pumps offer easy maintenance and self-priming capabilities, making them suitable for medical, pharmaceutical, and chemical dosing applications. Piston pumps provide superior accuracy and durability for industrial processes requiring consistent pressure and flow rates, such as hydraulics and fuel injection.

Peristaltic Pump vs Piston Pump Infographic

libmatt.com

libmatt.com