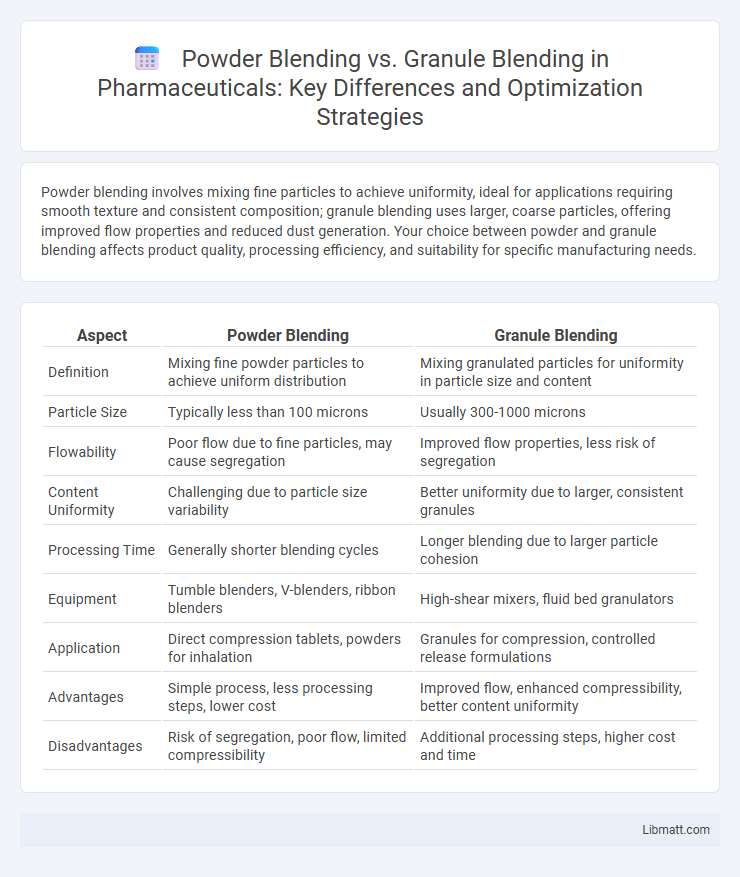

Powder blending involves mixing fine particles to achieve uniformity, ideal for applications requiring smooth texture and consistent composition; granule blending uses larger, coarse particles, offering improved flow properties and reduced dust generation. Your choice between powder and granule blending affects product quality, processing efficiency, and suitability for specific manufacturing needs.

Table of Comparison

| Aspect | Powder Blending | Granule Blending |

|---|---|---|

| Definition | Mixing fine powder particles to achieve uniform distribution | Mixing granulated particles for uniformity in particle size and content |

| Particle Size | Typically less than 100 microns | Usually 300-1000 microns |

| Flowability | Poor flow due to fine particles, may cause segregation | Improved flow properties, less risk of segregation |

| Content Uniformity | Challenging due to particle size variability | Better uniformity due to larger, consistent granules |

| Processing Time | Generally shorter blending cycles | Longer blending due to larger particle cohesion |

| Equipment | Tumble blenders, V-blenders, ribbon blenders | High-shear mixers, fluid bed granulators |

| Application | Direct compression tablets, powders for inhalation | Granules for compression, controlled release formulations |

| Advantages | Simple process, less processing steps, lower cost | Improved flow, enhanced compressibility, better content uniformity |

| Disadvantages | Risk of segregation, poor flow, limited compressibility | Additional processing steps, higher cost and time |

Introduction to Powder and Granule Blending

Powder blending involves the uniform mixing of fine, dry particles to achieve homogeneity in pharmaceutical, chemical, and food industries, ensuring consistent product quality and efficacy. Granule blending combines larger, coarse particles or agglomerates, improving flow properties and reducing dust generation, which enhances processing efficiency and safety. Both blending methods require precise control over particle size distribution, moisture content, and blend time to optimize product performance and stability.

Key Differences Between Powders and Granules

Powder blending involves combining fine particles with high surface area that flow easily but can generate dust, whereas granule blending uses larger, coarse particles with better flowability and reduced dust formation. Powders offer faster dissolution rates due to their small particle size, while granules provide improved compressibility and uniformity in compaction processes. Your choice between powder and granule blending depends on factors like product stability, mixing efficiency, and end-use application.

Importance of Blending in Manufacturing

Blending ensures uniform distribution of components, critical for consistent product quality and efficacy in manufacturing. Powder blending achieves homogeneity in fine particles, while granule blending handles larger, coarse materials to maintain mixture stability and flowability. Your choice between powder and granule blending directly impacts formulation performance, process efficiency, and final product reliability.

Blending Techniques for Powders

Powder blending techniques primarily include tumbling, ribbon blending, and paddle blending, each designed to achieve homogeneous mixtures with minimal segregation or particle size reduction. Tumbling blenders use a rotating drum to mix powders gently but are less effective for cohesive powders, while ribbon blenders utilize helical ribbons to create axial and radial flow, enhancing blending efficiency in free-flowing powders. Paddle blenders offer more aggressive mixing for cohesive or sticky powders by applying shear forces, making them suitable for formulations requiring uniform distribution of active ingredients.

Blending Techniques for Granules

Granule blending techniques often involve intensive mixing methods such as high-shear mixers and tumble blenders to ensure uniform particle distribution and prevent segregation. Unlike powder blending, granule blending requires careful control of moisture content and particle size to maintain product integrity and flow properties. Your choice of blending technique will directly impact the consistency and quality of the final granulated product.

Equipment Used in Powder vs Granule Blending

Powder blending predominantly utilizes ribbon blenders, V-blenders, and paddle mixers designed to handle fine particles with low cohesion, ensuring uniform mixing without particle degradation. Granule blending requires more robust equipment such as tumble blenders and drum blenders that accommodate larger, coarser particles and minimize breakage during mixing. Both processes rely on specialized blending machinery optimized for particle size and flow characteristics to achieve homogenous mixtures in pharmaceutical and chemical manufacturing.

Challenges in Powder Blending

Powder blending faces significant challenges such as achieving uniform particle distribution and preventing segregation due to differences in particle size, shape, and density. Factors like electrostatic charges, moisture content, and flowability further complicate the process, potentially impacting blend homogeneity and final product quality. Understanding these challenges allows you to optimize mixing parameters and select appropriate equipment to ensure consistent powder blends.

Challenges in Granule Blending

Granule blending presents challenges such as achieving uniform distribution due to varying particle sizes and densities, which can lead to segregation and inconsistent product quality. Equipment selection and process parameters must be carefully optimized to prevent granule breakage or over-mixing, which can alter the physical properties of the granules. Addressing these issues ensures your final blend meets stringent pharmaceutical or industrial specifications.

Quality Control in Blending Processes

Quality control in powder blending involves precise monitoring of particle size distribution and homogeneity to ensure uniformity and prevent segregation, critical for consistent product efficacy. Granule blending emphasizes the control of granule size and moisture content to maintain blend uniformity and optimize flow properties, reducing variability in dosage forms. Advanced analytical techniques such as near-infrared spectroscopy (NIR) and real-time particle size analysis are commonly employed to enhance quality assurance in both processes.

Applications and Industry Case Studies

Powder blending is widely used in pharmaceuticals for creating homogenous mixtures of active ingredients, ensuring consistent dosage in tablets and capsules, while granule blending is preferred in food processing to enhance flowability and compressibility in products like breakfast cereals. Industries such as chemical manufacturing rely on powder blending for fine chemicals, whereas granule blending dominates fertilizer production due to its ability to create uniform granules with precise nutrient distribution. Your choice between powder and granule blending impacts product quality and efficiency, as demonstrated in case studies from pharmaceutical firms optimizing drug formulations and agribusinesses improving soil nutrient delivery.

Powder Blending vs Granule Blending Infographic

libmatt.com

libmatt.com