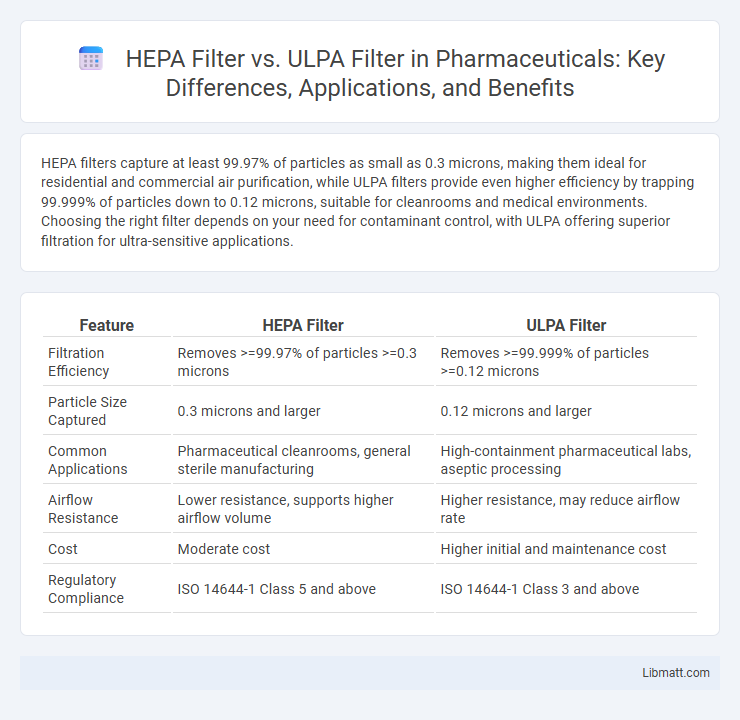

HEPA filters capture at least 99.97% of particles as small as 0.3 microns, making them ideal for residential and commercial air purification, while ULPA filters provide even higher efficiency by trapping 99.999% of particles down to 0.12 microns, suitable for cleanrooms and medical environments. Choosing the right filter depends on your need for contaminant control, with ULPA offering superior filtration for ultra-sensitive applications.

Table of Comparison

| Feature | HEPA Filter | ULPA Filter |

|---|---|---|

| Filtration Efficiency | Removes >=99.97% of particles >=0.3 microns | Removes >=99.999% of particles >=0.12 microns |

| Particle Size Captured | 0.3 microns and larger | 0.12 microns and larger |

| Common Applications | Pharmaceutical cleanrooms, general sterile manufacturing | High-containment pharmaceutical labs, aseptic processing |

| Airflow Resistance | Lower resistance, supports higher airflow volume | Higher resistance, may reduce airflow rate |

| Cost | Moderate cost | Higher initial and maintenance cost |

| Regulatory Compliance | ISO 14644-1 Class 5 and above | ISO 14644-1 Class 3 and above |

Introduction to HEPA and ULPA Filters

HEPA (High-Efficiency Particulate Air) filters capture 99.97% of particles as small as 0.3 microns, making them ideal for reducing allergens, dust, and airborne contaminants in homes and workplaces. ULPA (Ultra-Low Penetration Air) filters provide even higher efficiency by trapping 99.999% of particles down to 0.12 microns, offering superior protection in cleanrooms and environments requiring extreme air purity. Understanding the distinction between HEPA and ULPA filters helps you select the best air filtration system tailored to your specific needs.

What is a HEPA Filter?

A HEPA filter (High-Efficiency Particulate Air) is designed to trap at least 99.97% of airborne particles measuring 0.3 microns in diameter, including dust, pollen, mold, bacteria, and some viruses. It is commonly used in environments requiring high levels of air cleanliness, such as medical facilities, laboratories, and cleanrooms. HEPA filters provide effective filtration by utilizing dense layers of fine fibers that capture contaminants through interception, impaction, and diffusion processes.

What is an ULPA Filter?

An ULPA filter, or Ultra-Low Penetration Air filter, is designed to remove at least 99.999% of airborne particles as small as 0.12 microns, making it more efficient than a standard HEPA filter. These filters are commonly used in environments requiring extreme cleanliness, such as cleanrooms, pharmaceutical manufacturing, and aerospace applications. Your choice between a HEPA and ULPA filter should depend on the level of particle filtration needed for your specific use case.

Filtration Efficiency: HEPA vs ULPA

HEPA filters capture at least 99.97% of particles as small as 0.3 microns, making them highly effective for common airborne contaminants like dust, pollen, and pet dander. ULPA filters provide superior filtration efficiency, removing 99.999% of particles down to 0.12 microns, which is ideal for environments requiring extreme cleanliness such as cleanrooms and semiconductor manufacturing. The enhanced filtration capability of ULPA filters ensures better protection against ultrafine particles including viruses and smoke.

Applications of HEPA Filters

HEPA filters are widely used in medical facilities, cleanrooms, and HVAC systems to trap airborne particles as small as 0.3 microns, ensuring high air quality in sensitive environments. Your home air purifiers and vacuum cleaners also benefit from HEPA filters, effectively reducing allergens, dust, and pet dander. These filters are essential in environments where contamination control and respiratory health are top priorities.

Applications of ULPA Filters

ULPA filters are essential in environments demanding ultra-clean air, such as semiconductor manufacturing, pharmaceutical production, and aerospace industries, where particle removal efficiency is critical. These filters capture at least 99.999% of particles as small as 0.12 microns, ensuring contamination control in cleanrooms and sensitive laboratories. ULPA filters also serve in advanced medical facilities and nuclear industries, providing superior protection against microscopic hazardous particles.

Key Differences Between HEPA and ULPA Filters

HEPA filters remove at least 99.97% of airborne particles 0.3 microns in diameter, while ULPA filters capture 99.999% of particles as small as 0.12 microns, making ULPA filters superior for environments requiring extreme cleanliness. HEPA filters are commonly used in residential and commercial air purifiers, whereas ULPA filters are preferred in critical applications like cleanrooms, pharmaceutical manufacturing, and semiconductor production. Choosing the right filter for your needs depends on the required filtration efficiency and particle size capture for your specific environment.

Maintenance and Lifespan Comparison

HEPA filters typically require replacement every 6 to 12 months depending on usage and environmental conditions, whereas ULPA filters have a longer lifespan, often lasting up to 2 years due to their denser filtration media. Maintenance for HEPA filters involves regular inspections and vacuuming to prevent dust buildup, while ULPA filters demand more meticulous handling to avoid damage to their delicate fibers. Proper maintenance extends the lifespan of both filters, but ULPA filters generally offer a more durable performance in high-contamination environments.

Cost Considerations: HEPA vs ULPA

HEPA filters generally cost less upfront compared to ULPA filters, making them a more budget-friendly option for most residential and commercial applications. ULPA filters, with their higher particle capture efficiency (99.999% at 0.12 microns versus HEPA's 99.97% at 0.3 microns), come at a premium price due to advanced manufacturing and materials. Long-term maintenance and replacement costs also tend to be higher for ULPA filters because of their specialized use in cleanrooms and critical environments.

Choosing the Right Filter for Your Needs

HEPA filters capture 99.97% of particles as small as 0.3 microns, making them ideal for residential air purification and general healthcare environments, while ULPA filters trap 99.999% of particles down to 0.12 microns, suited for cleanrooms and semiconductor manufacturing. Your choice depends on the required level of air cleanliness and specific contaminants you need to control. Selecting the right filter ensures optimal air quality, protecting health and sensitive equipment efficiently.

HEPA Filter vs ULPA Filter Infographic

libmatt.com

libmatt.com