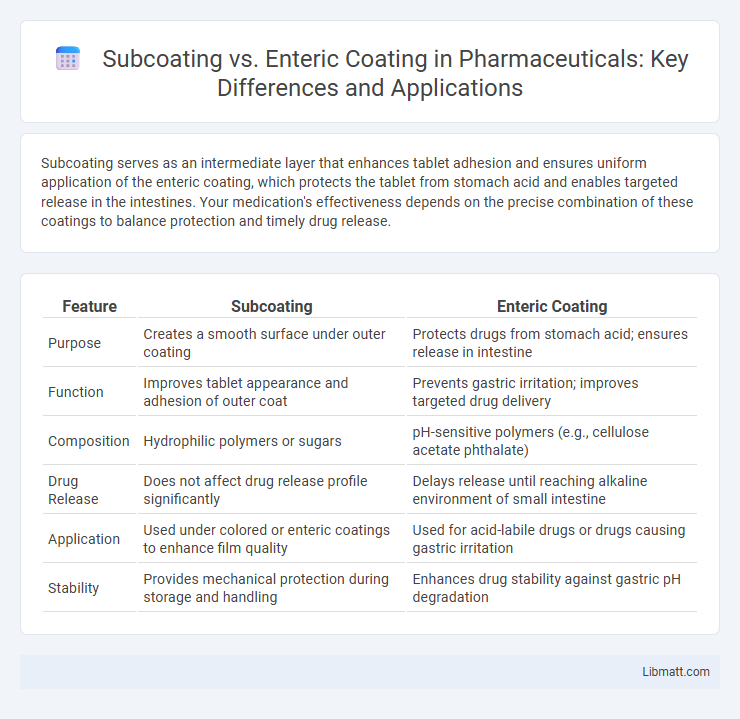

Subcoating serves as an intermediate layer that enhances tablet adhesion and ensures uniform application of the enteric coating, which protects the tablet from stomach acid and enables targeted release in the intestines. Your medication's effectiveness depends on the precise combination of these coatings to balance protection and timely drug release.

Table of Comparison

| Feature | Subcoating | Enteric Coating |

|---|---|---|

| Purpose | Creates a smooth surface under outer coating | Protects drugs from stomach acid; ensures release in intestine |

| Function | Improves tablet appearance and adhesion of outer coat | Prevents gastric irritation; improves targeted drug delivery |

| Composition | Hydrophilic polymers or sugars | pH-sensitive polymers (e.g., cellulose acetate phthalate) |

| Drug Release | Does not affect drug release profile significantly | Delays release until reaching alkaline environment of small intestine |

| Application | Used under colored or enteric coatings to enhance film quality | Used for acid-labile drugs or drugs causing gastric irritation |

| Stability | Provides mechanical protection during storage and handling | Enhances drug stability against gastric pH degradation |

Introduction to Tablet Coating Techniques

Tablet coating techniques play a crucial role in pharmaceutical formulations, primarily aimed at protecting active ingredients and controlling drug release. Subcoating provides a base layer to smooth out tablet surfaces and improve adhesion of subsequent layers, while enteric coating is designed to withstand stomach acid and dissolve only in the intestines, ensuring targeted drug delivery. Each coating method enhances tablet stability, patient compliance, and therapeutic efficacy through specific functional properties.

What is Subcoating?

Subcoating is a protective layer applied beneath the outer coating of a tablet or capsule to enhance adhesion and prevent interaction between the core and the enteric or film coating. This intermediate layer improves the durability and stability of the final dosage form by providing a smooth, uniform surface for subsequent coatings. Your medication's effectiveness can benefit from subcoating, as it ensures precise release and maintains integrity within the gastrointestinal tract.

Understanding Enteric Coating

Enteric coating is a specialized pharmaceutical polymer barrier applied to oral medication tablets or capsules to prevent dissolution in the acidic environment of the stomach, ensuring release occurs in the more neutral pH of the intestines. This coating protects acid-sensitive active ingredients from degradation and minimizes gastric irritation by bypassing stomach release. Unlike subcoating, which provides a cushioning layer to protect tablets from mechanical damage, enteric coatings are specifically designed to resist stomach acid and enable targeted drug delivery in the gastrointestinal tract.

Key Differences: Subcoating vs Enteric Coating

Subcoating serves as an intermediate layer that smoothens and strengthens the tablet core, improving adhesion and protecting the active ingredient, while enteric coating is specifically designed to resist stomach acid and dissolve in the more neutral or alkaline environment of the intestines. The primary difference lies in their functional purpose: subcoating enhances tablet durability and prepares the surface for further coating, whereas enteric coatings prevent premature drug release in the stomach, ensuring targeted delivery and reducing gastric irritation. Material composition also varies, with subcoatings often using polymers like hydroxypropyl methylcellulose (HPMC) and enteric coatings utilizing acid-resistant polymers such as cellulose acetate phthalate (CAP) or methacrylic acid copolymers.

Purposes and Applications of Subcoating

Subcoating serves primarily to protect the core of a tablet or capsule from moisture, enhance adhesion between the core and the outer coating, and improve the product's overall stability. It is commonly applied in pharmaceuticals to ensure uniformity and integrity before the enteric or functional coating is added to control drug release. Your formulations benefit from subcoating by improving the effectiveness and durability of subsequent coating layers.

Benefits and Limitations of Enteric Coating

Enteric coating provides targeted drug release by protecting medication from stomach acid, enhancing bioavailability and reducing gastrointestinal irritation. Benefits include improved drug stability and prevention of premature drug dissolution, which is critical for acid-sensitive compounds. Limitations involve higher production costs and potential variability in dissolution times, which can affect therapeutic consistency for your medication.

Impact on Drug Release Profiles

Subcoating creates a protective layer that controls the initial release rate by slowing drug dissolution, leading to a more gradual onset of action. Enteric coating prevents drug release in acidic gastric conditions and enables targeted release in the alkaline environment of the intestines, improving drug stability and absorption. The choice between subcoating and enteric coating significantly affects the drug's bioavailability and therapeutic efficacy by altering release timing and site in the gastrointestinal tract.

Material Selection for Each Coating Type

Subcoating materials typically consist of hydrophilic polymers such as hydroxypropyl methylcellulose (HPMC) or polyethylene glycol (PEG), which provide a smooth surface and improve the adhesion of enteric coatings. Enteric coatings use acid-resistant polymers like cellulose acetate phthalate (CAP), polyvinyl acetate phthalate (PVAP), or methacrylic acid copolymers to protect active pharmaceutical ingredients (APIs) from gastric acid degradation and ensure targeted release in the intestines. Material selection for each coating type focuses on compatibility with the drug core, dissolution environment, and desired release profile to optimize bioavailability and therapeutic efficacy.

Challenges in Manufacturing and Quality Control

Subcoating and enteric coating present distinct manufacturing challenges, with subcoating requiring precise control of film thickness to ensure uniform tablet protection, while enteric coating demands exact pH-sensitive polymer application to prevent premature drug release in the stomach. Quality control for subcoated tablets involves rigorous testing for adhesion and mechanical strength, whereas enteric-coated products necessitate dissolution testing under varying pH conditions to verify targeted release in the intestines. Your ability to manage these challenges directly impacts the consistency and efficacy of the final pharmaceutical product.

Choosing the Optimal Coating for Your Formulation

Selecting the optimal coating for your formulation depends on the desired drug release profile and stability requirements. Subcoating protects the core tablet from environmental factors and improves mechanical strength, making it ideal for moisture or light-sensitive APIs. Enteric coating targets drug release in the intestine by resisting stomach acid, ensuring proper absorption and minimizing gastrointestinal irritation.

Subcoating vs Enteric Coating Infographic

libmatt.com

libmatt.com