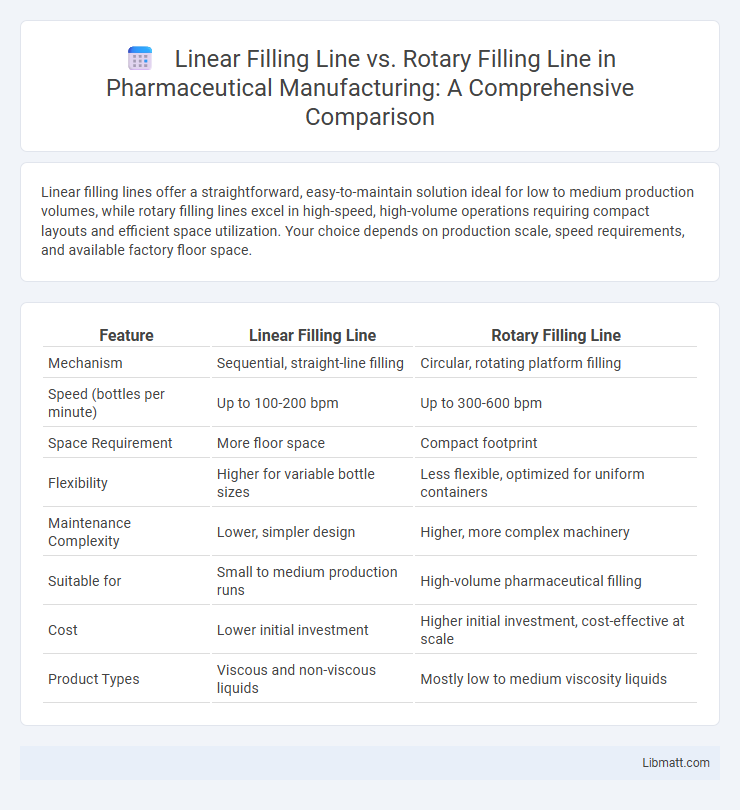

Linear filling lines offer a straightforward, easy-to-maintain solution ideal for low to medium production volumes, while rotary filling lines excel in high-speed, high-volume operations requiring compact layouts and efficient space utilization. Your choice depends on production scale, speed requirements, and available factory floor space.

Table of Comparison

| Feature | Linear Filling Line | Rotary Filling Line |

|---|---|---|

| Mechanism | Sequential, straight-line filling | Circular, rotating platform filling |

| Speed (bottles per minute) | Up to 100-200 bpm | Up to 300-600 bpm |

| Space Requirement | More floor space | Compact footprint |

| Flexibility | Higher for variable bottle sizes | Less flexible, optimized for uniform containers |

| Maintenance Complexity | Lower, simpler design | Higher, more complex machinery |

| Suitable for | Small to medium production runs | High-volume pharmaceutical filling |

| Cost | Lower initial investment | Higher initial investment, cost-effective at scale |

| Product Types | Viscous and non-viscous liquids | Mostly low to medium viscosity liquids |

Introduction to Filling Lines

Linear filling lines consist of a series of stations arranged in a straight line, ideal for moderate production speeds and easy customization. Rotary filling lines feature a circular arrangement with multiple filling heads working simultaneously, maximizing efficiency for high-volume production. Your choice between linear and rotary filling lines depends on factors like production speed, product type, and floor space availability.

Overview of Linear Filling Lines

Linear filling lines consist of a series of stations arranged in a straight line, designed to efficiently fill containers one at a time with high precision. These systems excel in handling a variety of container shapes and sizes, making them suitable for industries such as pharmaceuticals, cosmetics, and food and beverages. Your choice of a linear filling line ensures easy scalability, straightforward maintenance, and precise control over filling volumes.

Overview of Rotary Filling Lines

Rotary filling lines feature a circular design allowing multiple filling stations to operate simultaneously, significantly increasing production speed and efficiency compared to linear filling lines. These systems are ideal for high-volume bottling operations, with capabilities to handle a wide range of container sizes and shapes while maintaining consistent accuracy. Your choice of rotary filling lines can enhance throughput and reduce downtime in beverage, pharmaceutical, and cosmetic manufacturing industries.

Key Differences Between Linear and Rotary Filling Lines

Linear filling lines operate with a straight, sequential motion ideal for high-speed, low-to-medium volume production, while rotary filling lines use a circular, continuous motion designed for high-speed, large-volume output. The key difference lies in the machine layout and efficiency: linear lines offer flexibility for various container shapes and sizes, whereas rotary lines provide greater throughput and compact footprint but require consistent container specifications. Your choice depends on production volume, container type, and space availability, with rotary lines excelling in maximizing output and linear lines offering versatility.

Production Speed and Efficiency Comparison

Linear filling lines typically operate at moderate speeds, ranging from 1,000 to 5,000 bottles per hour, offering greater flexibility for smaller batch sizes and diverse container shapes. Rotary filling lines excel in high-speed production, achieving up to 20,000 bottles per hour with enhanced efficiency due to continuous motion and synchronized filling stations. The choice between linear and rotary filling lines hinges on production volume requirements, with rotary lines favored for large-scale, high-throughput operations and linear lines suited for medium to low production speeds.

Space Requirements and Footprint

Linear filling lines generally require more floor space due to their elongated, straight configuration, making them less ideal for facilities with limited footprints. Rotary filling lines offer a compact, circular layout that maximizes space efficiency by integrating multiple filling stations within a smaller area. Facilities prioritizing minimal space consumption often prefer rotary systems for high-speed production in confined environments.

Accuracy and Versatility

Linear Filling Lines offer high accuracy due to their precise, single-station filling mechanism, ideal for consistent volumes and simple container shapes. Rotary Filling Lines provide superior versatility by accommodating various product types and container sizes through multiple filling stations operating simultaneously. Your choice depends on whether you prioritize precise filling accuracy or adaptable production capacity across diverse packaging formats.

Maintenance and Operational Costs

Linear filling lines generally incur lower initial maintenance costs due to their simpler mechanical structure, which includes fewer moving parts compared to rotary systems. Rotary filling lines, though more complex and expensive to maintain, offer higher operational speeds and efficiency, leading to potentially lower cost per unit during large-scale production. Businesses should weigh the trade-off between lower upfront maintenance expenses and the long-term operational cost benefits when choosing the appropriate filling line for their production needs.

Best Applications for Linear vs Rotary Filling Lines

Linear filling lines are best suited for high-speed, small to medium-sized production runs with a variety of container shapes and sizes, offering flexibility and easy changeover for diverse product portfolios. Rotary filling lines excel in high-volume, uniform container filling, particularly in industries such as beverages and pharmaceuticals, where consistent speed and precision are critical for large-scale operations. Selecting between linear and rotary systems depends on production volume, container uniformity, and operational efficiency requirements.

Choosing the Right Filling Line for Your Business

Linear filling lines offer simplicity and cost-effectiveness for moderate production volumes, making them ideal for businesses seeking flexibility and easy maintenance. Rotary filling lines excel in high-speed, large-scale operations by maximizing output with continuous, efficient filling processes. Assess your production capacity, space constraints, and budget to determine which filling line best aligns with your business goals and operational demands.

Linear Filling Line vs Rotary Filling Line Infographic

libmatt.com

libmatt.com