Wet polishing reduces dust and heat buildup, extending the life of your tools and producing a smoother finish, while dry polishing offers faster results and easier cleanup in environments where water use is restricted. Choosing between wet and dry polishing depends on your specific project needs, material type, and workspace conditions.

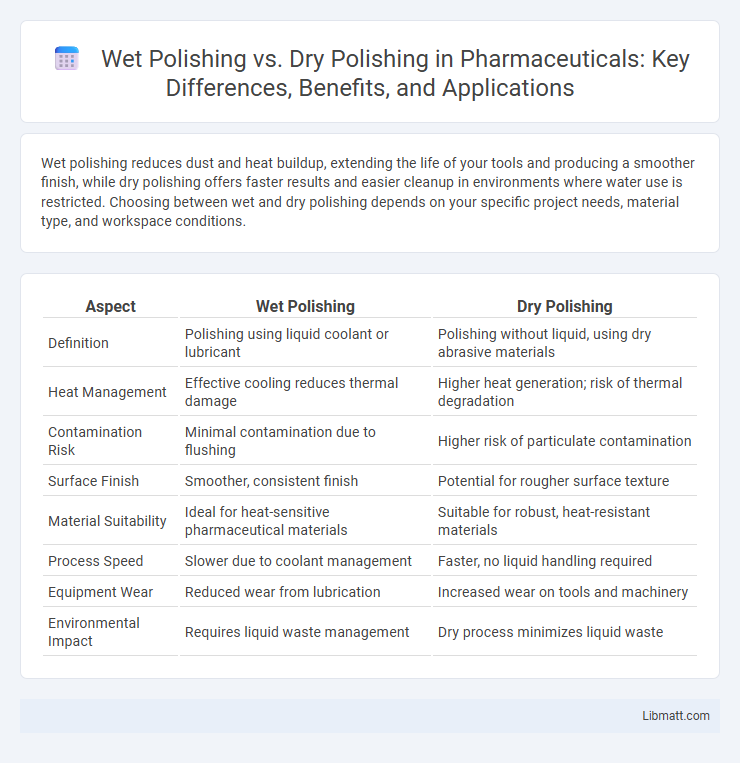

Table of Comparison

| Aspect | Wet Polishing | Dry Polishing |

|---|---|---|

| Definition | Polishing using liquid coolant or lubricant | Polishing without liquid, using dry abrasive materials |

| Heat Management | Effective cooling reduces thermal damage | Higher heat generation; risk of thermal degradation |

| Contamination Risk | Minimal contamination due to flushing | Higher risk of particulate contamination |

| Surface Finish | Smoother, consistent finish | Potential for rougher surface texture |

| Material Suitability | Ideal for heat-sensitive pharmaceutical materials | Suitable for robust, heat-resistant materials |

| Process Speed | Slower due to coolant management | Faster, no liquid handling required |

| Equipment Wear | Reduced wear from lubrication | Increased wear on tools and machinery |

| Environmental Impact | Requires liquid waste management | Dry process minimizes liquid waste |

Introduction to Wet Polishing and Dry Polishing

Wet polishing involves using water or a liquid coolant to reduce heat and dust during the polishing process, enhancing surface finish and prolonging tool life. Dry polishing, on the other hand, eliminates the use of liquids, relying on air cooling which can lead to higher temperatures and potential dust hazards. Understanding these methods helps you select the appropriate technique based on material sensitivity and desired surface quality.

Key Differences Between Wet and Dry Polishing

Wet polishing uses water or coolant to reduce heat and dust, enhancing surface finish and extending tool life, while dry polishing operates without liquids, generating more heat and dust but allowing faster processing and easier cleanup. Wet polishing is ideal for materials prone to heat damage or requiring fine finishes, whereas dry polishing suits harder materials and situations where water use is impractical. The choice depends on factors like material type, desired finish quality, environmental considerations, and equipment capabilities.

Advantages of Wet Polishing

Wet polishing offers superior cooling by continuously washing away heat and debris, which prevents surface damage and extends the lifespan of polishing tools. The presence of water reduces dust, creating a safer and cleaner work environment, while enhancing the quality of the finished surface with a smoother, more consistent polish. You benefit from improved precision and less risk of material distortion compared to dry polishing methods.

Benefits of Dry Polishing

Dry polishing offers the benefit of faster finishing times by eliminating the need for water cleanup, resulting in increased productivity for your projects. This method reduces the risk of water damage or stains on delicate surfaces, making it ideal for materials sensitive to moisture. Dry polishing tools are often more portable and easier to use in environments without water access, enhancing convenience and flexibility.

Comparison of Surface Finish Quality

Wet polishing provides a smoother and more reflective surface finish compared to dry polishing due to effective cooling and reduction of abrasive debris buildup. Dry polishing often results in higher surface roughness and potential micro-scratches because of heat generation and material removal inconsistencies. Choosing wet polishing enhances your final product's aesthetic appeal and durability by ensuring a superior surface texture.

Equipment and Tools: Wet vs Dry Polishing

Wet polishing requires specialized equipment such as water pumps and wet grinders designed to handle continuous water flow, ensuring the surface remains cool and dust-free. Dry polishing tools are typically equipped with advanced dust extraction systems and high-speed motors to prevent overheating and manage debris effectively. Your choice between wet and dry polishing equipment depends on the material, desired finish, and environmental considerations.

Safety Considerations for Both Methods

Wet polishing reduces dust and heat generation, significantly lowering the risk of respiratory issues and surface damage, making it safer for prolonged use. Dry polishing can increase airborne particulates, posing health hazards without proper ventilation or protective gear, and may cause overheating, risking burns or material degradation. Ensuring your workspace has adequate dust extraction and using appropriate personal protective equipment enhances safety regardless of the chosen polishing method.

Environmental Impact: Water Usage and Dust Control

Wet polishing significantly reduces airborne dust particles, improving air quality and protecting worker health by using water to suppress dust. This method, however, involves substantial water consumption, necessitating efficient water management practices to minimize environmental strain. Your choice between wet and dry polishing should balance dust control benefits against water usage, considering the specific environmental and regulatory context.

Choosing the Right Polishing Method for Your Project

Choosing the right polishing method depends on the material and desired finish for your project. Wet polishing uses water to reduce dust and heat, offering a smoother finish for stone or concrete surfaces. Dry polishing is faster and more convenient for smaller projects but may produce more dust and heat, requiring proper ventilation and protective gear for Your safety.

Conclusion: Wet Polishing vs Dry Polishing – Which is Best?

Wet polishing offers superior dust control and a smoother finish by using water to cool and lubricate the surface, making it ideal for delicate materials and extended work sessions. Dry polishing provides faster drying times and easier cleanup but poses higher risks of surface scratches and dust inhalation. Your choice depends on the project requirements, balancing precision and safety with speed and convenience.

Wet Polishing vs Dry Polishing Infographic

libmatt.com

libmatt.com