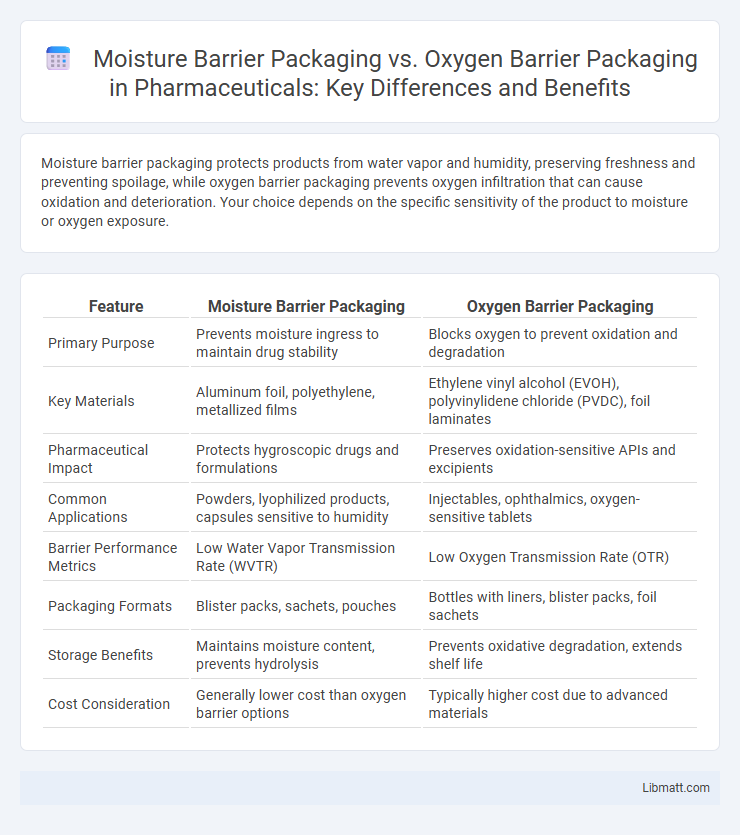

Moisture barrier packaging protects products from water vapor and humidity, preserving freshness and preventing spoilage, while oxygen barrier packaging prevents oxygen infiltration that can cause oxidation and deterioration. Your choice depends on the specific sensitivity of the product to moisture or oxygen exposure.

Table of Comparison

| Feature | Moisture Barrier Packaging | Oxygen Barrier Packaging |

|---|---|---|

| Primary Purpose | Prevents moisture ingress to maintain drug stability | Blocks oxygen to prevent oxidation and degradation |

| Key Materials | Aluminum foil, polyethylene, metallized films | Ethylene vinyl alcohol (EVOH), polyvinylidene chloride (PVDC), foil laminates |

| Pharmaceutical Impact | Protects hygroscopic drugs and formulations | Preserves oxidation-sensitive APIs and excipients |

| Common Applications | Powders, lyophilized products, capsules sensitive to humidity | Injectables, ophthalmics, oxygen-sensitive tablets |

| Barrier Performance Metrics | Low Water Vapor Transmission Rate (WVTR) | Low Oxygen Transmission Rate (OTR) |

| Packaging Formats | Blister packs, sachets, pouches | Bottles with liners, blister packs, foil sachets |

| Storage Benefits | Maintains moisture content, prevents hydrolysis | Prevents oxidative degradation, extends shelf life |

| Cost Consideration | Generally lower cost than oxygen barrier options | Typically higher cost due to advanced materials |

Introduction to Barrier Packaging

Barrier packaging is essential for preserving product quality by preventing contamination from external elements. Moisture barrier packaging specifically protects goods from humidity and water vapor, maintaining freshness and preventing spoilage. Oxygen barrier packaging, on the other hand, inhibits oxygen ingress to slow oxidation and microbial growth, extending shelf life and preserving flavor and color.

Importance of Moisture and Oxygen Control

Moisture barrier packaging is essential for preventing water vapor from compromising product integrity, preserving texture, flavor, and shelf life by maintaining optimal humidity levels. Oxygen barrier packaging plays a crucial role in inhibiting oxidation, which can lead to spoilage, discoloration, and nutrient loss in food and pharmaceutical products. Your choice between moisture and oxygen barrier packaging directly impacts product freshness, safety, and overall quality during storage and distribution.

What is Moisture Barrier Packaging?

Moisture barrier packaging is designed to prevent water vapor from penetrating products, thereby maintaining product freshness and extending shelf life. It utilizes materials such as polyethylene, polyvinylidene chloride (PVDC), or metalized films to resist moisture ingress effectively. This type of packaging is essential for moisture-sensitive items like pharmaceuticals, electronics, and food products prone to spoilage from humidity.

What is Oxygen Barrier Packaging?

Oxygen barrier packaging is designed to prevent oxygen molecules from penetrating and degrading product quality, thereby extending shelf life for food, pharmaceuticals, and electronics. This type of packaging commonly utilizes materials like ethylene vinyl alcohol (EVOH), silicon oxide, and aluminum foil to achieve low oxygen transmission rates. Protecting products from oxidation helps maintain freshness, flavor, and potency by minimizing spoilage and chemical changes caused by oxygen exposure.

Key Materials Used in Moisture Barrier Packaging

Moisture barrier packaging primarily utilizes materials such as polyethylene (PE), polypropylene (PP), and metallized films like aluminum foil to prevent water vapor transmission and maintain product freshness. These materials are often combined in multilayer laminates to enhance moisture resistance while preserving flexibility and durability. Your choice of packaging material depends on the product's sensitivity to moisture and the required shelf life.

Key Materials Used in Oxygen Barrier Packaging

Oxygen barrier packaging primarily utilizes materials such as ethylene vinyl alcohol (EVOH), polyvinylidene chloride (PVDC), and metallized films to effectively prevent oxygen transmission and preserve product freshness. EVOH is highly valued for its excellent gas barrier properties and transparency, making it suitable for food packaging applications requiring extended shelf life. Your choice of packaging can significantly impact the protection level against oxidation and spoilage, ensuring product quality and consumer safety.

Comparative Benefits: Moisture vs. Oxygen Barriers

Moisture barrier packaging protects products from humidity and water vapor, preventing spoilage, corrosion, and sogginess, which is vital for food, pharmaceuticals, and electronics. Oxygen barrier packaging blocks oxygen exposure, reducing oxidation and extending shelf life by maintaining product freshness and preventing microbial growth. Your choice depends on whether moisture sensitivity or oxygen degradation poses the greater risk to product quality and longevity.

Application Areas: Choosing the Right Barrier

Moisture barrier packaging is essential for products prone to spoilage from humidity, such as snacks, pharmaceuticals, and electronics, ensuring extended shelf life and product integrity. Oxygen barrier packaging is critical for perishable food items like meats, cheeses, and baked goods, preventing oxidation and preserving freshness and flavor. Selecting the right barrier depends on the specific product requirements, storage conditions, and shelf life objectives to optimize protection and maintain quality.

Packaging Performance and Shelf Life Impact

Moisture barrier packaging excels at preventing water vapor transmission, protecting products from humidity-related degradation and extending shelf life for moisture-sensitive items like snacks and pharmaceuticals. Oxygen barrier packaging effectively blocks oxygen infiltration, reducing oxidation and spoilage, which is critical for preserving freshness and color in products such as coffee and cured meats. Choosing the right barrier packaging aligns with your product's sensitivity, directly impacting packaging performance and prolonging shelf life based on the specific environmental threats.

Future Trends in Barrier Packaging Technologies

Future trends in barrier packaging technologies emphasize enhanced multi-layer structures combining moisture barrier packaging and oxygen barrier packaging to improve shelf life and product integrity. Advanced materials such as nanocomposites and bio-based polymers are being developed to provide superior protection against both moisture and oxygen transmission rates. Integration of smart sensors within barrier packaging systems is expected to monitor environmental conditions, further optimizing freshness and quality control in food and pharmaceutical industries.

Moisture barrier packaging vs Oxygen barrier packaging Infographic

libmatt.com

libmatt.com