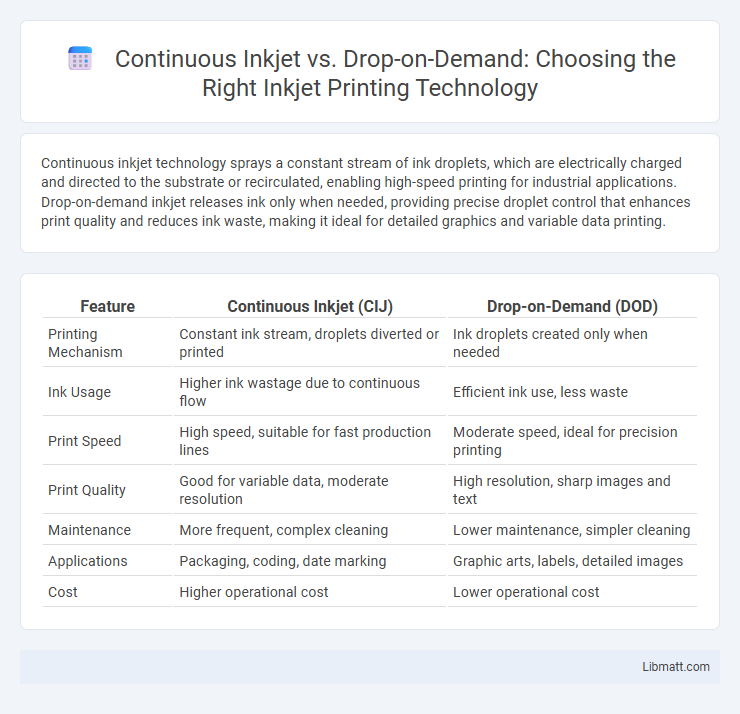

Continuous inkjet technology sprays a constant stream of ink droplets, which are electrically charged and directed to the substrate or recirculated, enabling high-speed printing for industrial applications. Drop-on-demand inkjet releases ink only when needed, providing precise droplet control that enhances print quality and reduces ink waste, making it ideal for detailed graphics and variable data printing.

Table of Comparison

| Feature | Continuous Inkjet (CIJ) | Drop-on-Demand (DOD) |

|---|---|---|

| Printing Mechanism | Constant ink stream, droplets diverted or printed | Ink droplets created only when needed |

| Ink Usage | Higher ink wastage due to continuous flow | Efficient ink use, less waste |

| Print Speed | High speed, suitable for fast production lines | Moderate speed, ideal for precision printing |

| Print Quality | Good for variable data, moderate resolution | High resolution, sharp images and text |

| Maintenance | More frequent, complex cleaning | Lower maintenance, simpler cleaning |

| Applications | Packaging, coding, date marking | Graphic arts, labels, detailed images |

| Cost | Higher operational cost | Lower operational cost |

Introduction to Inkjet Printing Technologies

Continuous inkjet (CIJ) technology propels a constant stream of ink droplets, deflected by electrical charges to create precise patterns on a substrate. Drop-on-Demand (DOD) inkjet ejects ink droplets selectively when required, offering high-resolution printing with minimal ink waste. Both methods are widely used in industrial labeling, packaging, and high-speed printing applications, with CIJ excelling in fast coding and DOD favored for variable data and detailed images.

What is Continuous Inkjet (CIJ)?

Continuous Inkjet (CIJ) technology involves a continuous stream of ink droplets electrically charged and deflected to form precise, high-speed printing patterns on various surfaces. This method excels in industrial applications due to its ability to produce clear, durable codes and markings on diverse materials like plastics, metals, and glass. Understanding how CIJ operates can help you select the most efficient printing solution for your production line requirements.

Understanding Drop-on-Demand (DOD) Inkjet

Drop-on-Demand (DOD) inkjet technology precisely controls ink ejection, producing droplets only when required, which reduces ink waste and enhances print quality. In contrast to Continuous Inkjet (CIJ) systems that constantly emit droplets, DOD inkjet offers improved accuracy and efficiency by activating nozzles solely during print commands. Your choice of DOD technology can lead to sharper images and cost-effective ink usage in various printing applications.

Key Differences Between CIJ and DOD

Continuous Inkjet (CIJ) systems emit a steady stream of ink droplets, allowing for high-speed and continuous marking, while Drop-on-Demand (DOD) printers eject ink only when needed, reducing ink waste and enabling precise placement. CIJ is ideal for fast-moving production lines with varied surfaces, offering durability and versatility, whereas DOD excels in applications requiring high-resolution imaging and minimal ink usage. Your choice depends on production speed, print quality, and cost-effectiveness requirements.

Print Quality Comparison: CIJ vs DOD

Continuous Inkjet (CIJ) technology offers high-speed printing with consistent droplet size, making it ideal for fast-moving production lines, but its print quality can be less precise compared to Drop-on-Demand (DOD) printers. DOD printers produce droplets only when needed, resulting in sharper images, finer detail, and higher resolution, which is optimal for intricate designs and small text. Your choice depends on prioritizing either production speed with reasonable quality (CIJ) or superior print clarity and precision (DOD).

Speed and Productivity Analysis

Continuous inkjet (CIJ) systems offer high-speed printing with the capability to produce thousands of droplets per second, making them ideal for high-volume, fast-paced industrial applications. Drop-on-demand (DOD) technology provides precise ink placement by ejecting droplets only when needed, which enhances print quality but typically results in slower throughput compared to CIJ. Understanding your production speed requirements will help determine whether CIJ's rapid output or DOD's accuracy best supports your productivity goals.

Ink and Maintenance Requirements

Continuous inkjet printers require a constant flow of ink through the nozzle, leading to higher ink consumption and more frequent cleaning to prevent clogging, while drop-on-demand printers release ink only when needed, optimizing ink usage and reducing waste. Maintenance for continuous inkjet systems often involves regular nozzle cleaning and ink filtering to avoid buildup and ensure consistent print quality. You will find drop-on-demand printers generally demand less upkeep and have simpler ink management, making them suitable for applications where lower maintenance and precise ink application are priorities.

Application Suitability: CIJ vs DOD

Continuous Inkjet (CIJ) excels in high-speed industrial applications such as coding and marking on packaging where non-contact, fast, and reliable printing of variable data on diverse substrates is critical. Drop-on-Demand (DOD) technology is better suited for precision printing tasks requiring controlled droplet size and placement, including high-resolution graphics, textile printing, and 3D printing applications. CIJ's ability to print on uneven or moving surfaces contrasts with DOD's advantage in customizable drop control for detailed and complex print jobs.

Cost Considerations and ROI

Continuous inkjet printers generally have higher upfront costs due to complex components but offer lower per-print expenses for large-volume runs, resulting in quicker ROI for high-demand environments. Drop-on-demand printers feature lower initial investments and reduced ink waste, making them cost-effective for smaller businesses or sporadic use, though ROI may be slower if print volume increases significantly. You should evaluate your production scale and frequency to determine which technology maximizes cost efficiency and accelerates return on investment.

Choosing the Right Technology for Your Needs

Continuous inkjet (CIJ) technology excels in high-speed, industrial applications requiring rapid, non-contact printing on various surfaces with durable inks. Drop-on-demand (DOD) systems suit precise, low-volume tasks, offering controlled ink placement and reduced waste for detailed images or variable data printing. Selecting the right technology depends on production speed, substrate type, ink compatibility, and budget constraints to maximize efficiency and print quality.

Continuous inkjet vs drop-on-demand Infographic

libmatt.com

libmatt.com