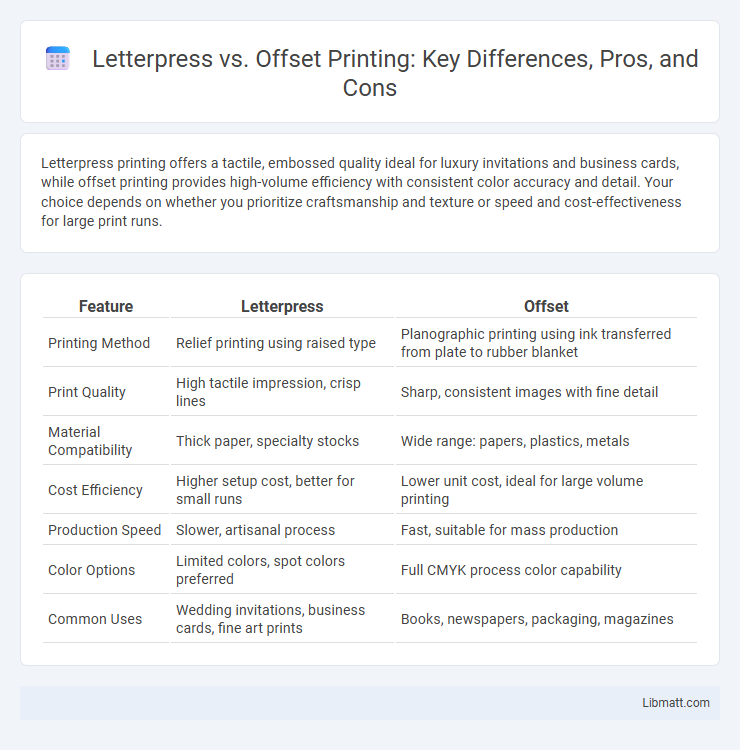

Letterpress printing offers a tactile, embossed quality ideal for luxury invitations and business cards, while offset printing provides high-volume efficiency with consistent color accuracy and detail. Your choice depends on whether you prioritize craftsmanship and texture or speed and cost-effectiveness for large print runs.

Table of Comparison

| Feature | Letterpress | Offset |

|---|---|---|

| Printing Method | Relief printing using raised type | Planographic printing using ink transferred from plate to rubber blanket |

| Print Quality | High tactile impression, crisp lines | Sharp, consistent images with fine detail |

| Material Compatibility | Thick paper, specialty stocks | Wide range: papers, plastics, metals |

| Cost Efficiency | Higher setup cost, better for small runs | Lower unit cost, ideal for large volume printing |

| Production Speed | Slower, artisanal process | Fast, suitable for mass production |

| Color Options | Limited colors, spot colors preferred | Full CMYK process color capability |

| Common Uses | Wedding invitations, business cards, fine art prints | Books, newspapers, packaging, magazines |

Introduction to Letterpress and Offset Printing

Letterpress printing uses a relief technique where raised surfaces are inked and pressed onto paper, producing crisp impressions ideal for invitations and art prints. Offset printing transfers ink from a plate to a rubber blanket, then onto paper, enabling high-quality, consistent results for large-volume runs. This distinction in process impacts texture, detail, and production scale between the two printing methods.

Historical Evolution of Printing Methods

Letterpress printing, dating back to the 15th century with Johannes Gutenberg's invention, revolutionized mass communication by introducing movable type and impression-based text. Offset printing emerged in the early 20th century, utilizing a rubber blanket to transfer ink from a plate to the paper, enabling high-volume, high-quality, and cost-efficient production. Your understanding of these historical printing methods highlights the shift from tactile, manual processes to automated, precision-driven technologies in the print industry.

How Letterpress Printing Works

Letterpress printing works by pressing inked raised surfaces directly onto paper, creating a tactile impression that enhances texture and depth in your designs. This traditional technique uses a metal or polymer plate, carefully inked and then pressed under high pressure, making it ideal for artisanal, high-quality prints such as wedding invitations or business cards. Unlike offset printing, which transfers ink indirectly, letterpress delivers sharp, crisp lines with a distinctive debossed effect that adds a luxurious, handcrafted feel.

How Offset Printing Works

Offset printing works by transferring ink from a metal plate to a rubber blanket and then onto the printing surface, allowing for high-quality, consistent images. This indirect process prevents damage to the printing plate, extending its usability for large-volume runs. Your materials benefit from precise color reproduction and sharp detail, making offset ideal for bulk printing with diverse paper types.

Print Quality Comparison

Letterpress printing delivers deep, tactile impressions with rich ink coverage that enhances texture and creates a distinct, artisanal finish, ideal for stationery and high-end invitations. Offset printing provides sharp, consistent image quality with precise color reproduction and smooth gradients, making it suitable for mass production of books, magazines, and brochures. The choice depends on the desired aesthetic: letterpress emphasizes texture and depth, while offset prioritizes fine detail and vibrant color accuracy.

Cost Efficiency and Production Volume

Letterpress printing typically incurs higher costs for small production volumes due to setup expenses and slower run speeds, making it less cost-efficient for large runs. Offset printing offers greater cost efficiency and faster production speeds, especially suited for high-volume jobs, reducing the per-unit cost significantly as volume increases. Your choice depends on balancing initial investment against volume needs, with offset favored for large-scale projects and letterpress ideal for smaller, artisanal prints.

Suitability for Different Project Types

Letterpress excels in creating tactile, high-end invitations, business cards, and artisanal packaging due to its deep impression and textured finish. Offset printing is more suitable for large-scale projects such as brochures, magazines, and catalogs, offering precise color reproduction and cost efficiency for high-volume jobs. Your choice depends on the desired aesthetic and project scale, with letterpress adding a classic, handcrafted feel and offset providing versatility and speed.

Environmental Impact and Sustainability

Letterpress printing has a smaller environmental footprint due to its use of fewer chemicals and less waste compared to offset printing, which often relies on petroleum-based inks and generates significant plate and chemical waste. Offset printing consumes more energy and water in its production process, contributing to higher greenhouse gas emissions and resource depletion. Sustainable practices in letterpress include using soy-based inks and recycled papers, while offset printing sustainability depends on adopting eco-friendly inks and waste reduction technologies.

Common Uses and Applications

Letterpress printing excels in creating tactile, high-quality invitations, business cards, and artisanal packaging, where texture and craftsmanship matter most. Offset printing is preferred for large-scale projects such as magazines, brochures, and newspapers due to its speed, cost-efficiency, and consistent color reproduction. Your choice depends on whether you prioritize the unique feel of letterpress or the volume and clarity of offset printing.

Choosing the Right Printing Method

Choosing the right printing method depends on your project's requirements for quality, cost, and volume. Letterpress offers a tactile, vintage appeal with deep impressions ideal for luxury invitations, while offset printing excels in high-volume runs with consistent color accuracy and cost-efficiency. Understanding your design's detail, budget constraints, and desired finish will help you select the optimal technique to achieve professional results.

Letterpress vs offset Infographic

libmatt.com

libmatt.com