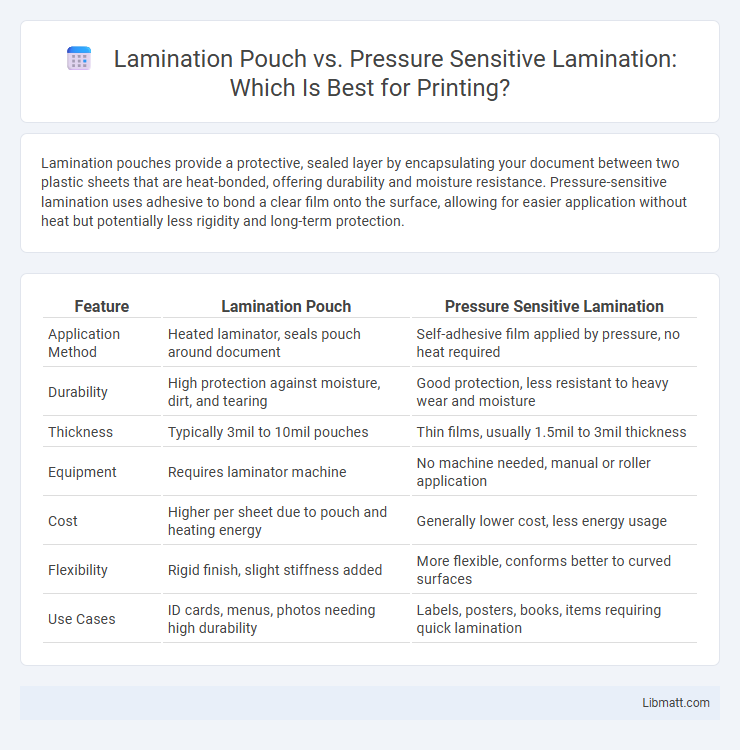

Lamination pouches provide a protective, sealed layer by encapsulating your document between two plastic sheets that are heat-bonded, offering durability and moisture resistance. Pressure-sensitive lamination uses adhesive to bond a clear film onto the surface, allowing for easier application without heat but potentially less rigidity and long-term protection.

Table of Comparison

| Feature | Lamination Pouch | Pressure Sensitive Lamination |

|---|---|---|

| Application Method | Heated laminator, seals pouch around document | Self-adhesive film applied by pressure, no heat required |

| Durability | High protection against moisture, dirt, and tearing | Good protection, less resistant to heavy wear and moisture |

| Thickness | Typically 3mil to 10mil pouches | Thin films, usually 1.5mil to 3mil thickness |

| Equipment | Requires laminator machine | No machine needed, manual or roller application |

| Cost | Higher per sheet due to pouch and heating energy | Generally lower cost, less energy usage |

| Flexibility | Rigid finish, slight stiffness added | More flexible, conforms better to curved surfaces |

| Use Cases | ID cards, menus, photos needing high durability | Labels, posters, books, items requiring quick lamination |

Introduction to Lamination Types

Lamination pouches consist of a plastic film sealed around a document using heat and pressure, providing durability and moisture resistance ideal for preserving important papers. Pressure-sensitive lamination involves an adhesive-backed film that bonds to surfaces without heat, enabling quick application on various materials including photos and signs. Both methods enhance print longevity but differ in application technique and suitable use cases, with lamination pouches favored for professional documents and pressure-sensitive lamination suited for flexible, on-demand finishes.

What is Lamination Pouch?

A lamination pouch is a sealed plastic film used to encase documents, providing protection and durability through heat and pressure application. It is designed to shield your important papers from water, dirt, and wear, enhancing longevity and visual appeal. Unlike pressure-sensitive lamination, lamination pouches require a thermal laminator to activate the adhesive and create a secure bond.

What is Pressure Sensitive Lamination?

Pressure sensitive lamination is a process that uses an adhesive-coated film applied to a surface by pressure without heat or solvents. Unlike lamination pouches, which require a heat-sealing machine, pressure sensitive lamination offers immediate adhesion and easier application on items like printed materials, packaging, and labels. Your choice depends on the need for durability, flexibility, and production speed in protecting or enhancing the appearance of documents or products.

Key Differences Between Lamination Pouch and Pressure Sensitive Lamination

Lamination pouch involves sealing a document between two plastic sheets using heat, creating a rigid, durable finish that enhances protection and longevity. Pressure sensitive lamination uses an adhesive film that bonds to the surface through pressure alone, offering a quicker, no-heat application ideal for delicate materials. Your choice depends on whether you prioritize a sturdier, more permanent seal with lamination pouches or a flexible, faster solution with pressure sensitive lamination.

Application Areas for Each Lamination Type

Lamination pouches are widely used in educational materials, ID cards, menus, and documents requiring a durable, glossy finish and protection against moisture and wear. Pressure-sensitive lamination is ideal for signage, posters, and graphics that need easy application on flat or slightly curved surfaces, providing a matte or glossy finish with strong adhesion. Both lamination types serve different industry needs, with lamination pouches excelling in personal item protection and pressure-sensitive lamination preferred for commercial displays and promotional materials.

Durability and Protection Comparison

Lamination pouch offers superior durability by fully encasing documents in a heat-sealed plastic layer, protecting against moisture, dirt, and tears with a rigid finish. Pressure sensitive lamination relies on adhesive films, providing decent protection while allowing for easier application and removability but typically less resistance to heavy wear and liquids. You should choose lamination pouch for long-term preservation and pressure sensitive lamination for quick, flexible protection needs.

Cost Analysis: Lamination Pouch vs Pressure Sensitive Lamination

Lamination pouches typically involve higher material costs due to their sealed polyethylene or polypropylene films, whereas pressure-sensitive lamination often incurs lower material expenses since it uses adhesive-coated films without heat or pressure requirements. Equipment costs for lamination pouches include heated rollers or pouches machines, which can be more expensive compared to the relatively low-cost application tools needed for pressure-sensitive lamination. Overall, pressure-sensitive lamination offers cost advantages in both materials and operational expenses, making it a more economical choice for short-run or small-scale lamination projects.

Ease of Use and Application Process

Lamination pouches offer straightforward, user-friendly application by simply inserting the document and running it through a thermal laminator, making them ideal for quick, manual use. Pressure-sensitive lamination involves a peel-and-stick adhesive film that requires precise alignment but eliminates the need for heat, providing flexibility for uneven surfaces and on-the-go applications. Your choice depends on the balance between ease of setup and the nature of the items you need to laminate.

Visual Quality and Finish

Lamination pouches provide a glossy, smooth finish that enhances color vibrancy and offers consistent protection against wear and moisture. Pressure-sensitive lamination delivers a thinner, more flexible film with a matte or gloss finish, maintaining print clarity while allowing for easier application on irregular surfaces. Both methods improve visual quality, but lamination pouches generally produce a more durable, high-gloss appearance, whereas pressure-sensitive lamination offers customizable texture options and quicker adhesion.

Which Lamination Method is Best for Your Needs?

Choosing between lamination pouch and pressure sensitive lamination depends on your specific requirements for durability, ease of use, and application environment. Lamination pouches provide a heat-sealed, rigid protective layer ideal for long-term preservation of documents and photos, while pressure sensitive lamination offers a flexible, peel-and-stick solution perfect for quick application and surface versatility. Understanding Your need for either permanent protection or temporary adhesion will guide you to the best lamination method for your project.

lamination pouch vs pressure sensitive lamination Infographic

libmatt.com

libmatt.com