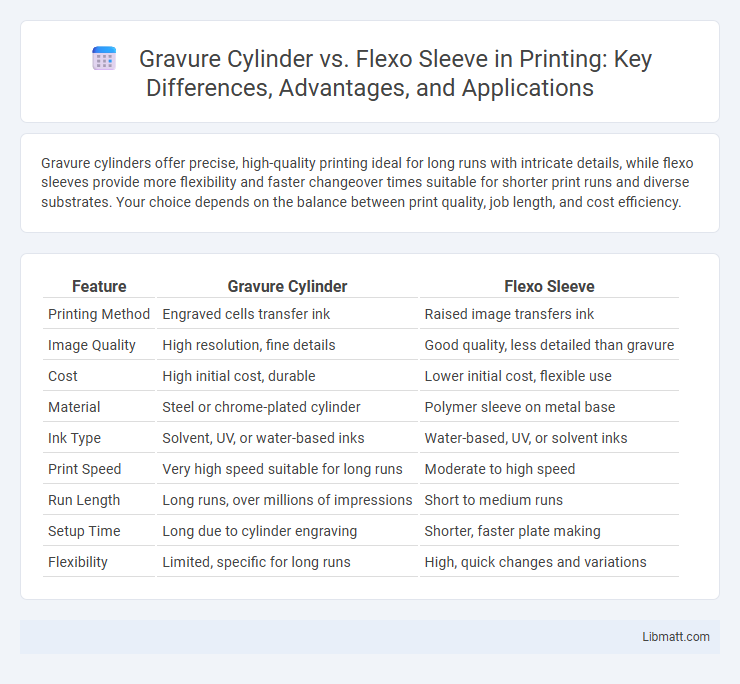

Gravure cylinders offer precise, high-quality printing ideal for long runs with intricate details, while flexo sleeves provide more flexibility and faster changeover times suitable for shorter print runs and diverse substrates. Your choice depends on the balance between print quality, job length, and cost efficiency.

Table of Comparison

| Feature | Gravure Cylinder | Flexo Sleeve |

|---|---|---|

| Printing Method | Engraved cells transfer ink | Raised image transfers ink |

| Image Quality | High resolution, fine details | Good quality, less detailed than gravure |

| Cost | High initial cost, durable | Lower initial cost, flexible use |

| Material | Steel or chrome-plated cylinder | Polymer sleeve on metal base |

| Ink Type | Solvent, UV, or water-based inks | Water-based, UV, or solvent inks |

| Print Speed | Very high speed suitable for long runs | Moderate to high speed |

| Run Length | Long runs, over millions of impressions | Short to medium runs |

| Setup Time | Long due to cylinder engraving | Shorter, faster plate making |

| Flexibility | Limited, specific for long runs | High, quick changes and variations |

Introduction to Gravure Cylinders and Flexo Sleeves

Gravure cylinders and flexo sleeves are essential components in high-quality printing processes, each designed to transfer ink with precision onto various substrates. Gravure cylinders are engraved with tiny cells that hold ink, allowing for detailed and consistent image reproduction, especially in packaging and label printing. Flexo sleeves, made from flexible materials, enable quick and cost-effective plate changes, improving your production efficiency in flexographic printing applications.

Historical Development of Printing Cylinders and Sleeves

Gravure cylinders emerged in the early 20th century as the primary method for high-quality, long-run printing, utilizing etched cells to hold ink for detailed images. Flexo sleeves were developed later as a flexible alternative to traditional engraved cylinders, offering quicker changeovers and improved efficiency in flexographic printing. The evolution from bulky gravure cylinders to lightweight flexo sleeves reflects advances in material technology and the increasing demand for faster, cost-effective packaging production.

Technical Overview: Gravure Cylinder Construction

Gravure cylinder construction involves etching tiny cells onto a metal surface, typically chrome-plated copper, to create precise ink wells for high-quality printing. This intricate process allows for detailed image reproduction and consistent ink transfer, making it ideal for long print runs. Your print quality benefits from the durability and precision engineering of gravure cylinders compared to flexo sleeves.

Technical Overview: Flexo Sleeve Design

Flexo sleeve design features a lightweight, flexible cylinder made from aluminum or composite materials, enabling high-speed rotation and quick changeovers. The sleeve includes an elastomeric surface for ink transfer, ensuring precise image reproduction and consistent print quality. Its modular design reduces setup time and waste compared to traditional gravure cylinders, enhancing efficiency in flexographic printing processes.

Print Quality Comparison: Gravure vs Flexo

Gravure cylinders deliver superior print quality with consistent high-resolution images and sharp details due to their engraved cells, making them ideal for complex graphics and fine gradients. Flexo sleeves tend to produce slightly lower resolution prints because of their photopolymer plates, which may result in less detail and limited tonal range compared to gravure. Despite this, flexo technology offers faster setup times and flexibility for shorter print runs, while gravure excels in large-volume, high-precision applications.

Cost Analysis: Gravure Cylinders vs Flexo Sleeves

Gravure cylinders typically involve higher initial manufacturing costs due to the intricate engraving process and durable steel or copper construction, impacting the overall cost analysis compared to flexo sleeves. Flexo sleeves offer cost advantages with lower production expenses and faster manufacturing times, making them more economical for short to medium print runs. Maintenance costs also favor flexo sleeves, as their replaceable nature reduces downtime and tooling expenses relative to the more permanent gravure cylinders.

Setup and Changeover Efficiency

Gravure cylinders require precise engraving and mounting, leading to longer setup and changeover times compared to flexo sleeves. Flexo sleeves offer faster changeover due to their lightweight design and ease of handling, reducing downtime during print runs. This efficiency advantage makes flexo sleeves ideal for short to medium runs where quick job changes are critical.

Durability and Lifespan Differences

Gravure cylinders typically offer superior durability and a longer lifespan due to their etched design, which resists wear and maintains print quality over extensive runs. Flexo sleeves, while more cost-effective and easier to replace, tend to have a shorter lifespan as their photopolymer surfaces wear down faster under high-volume or abrasive printing conditions. Understanding these durability differences helps you choose the most efficient option for your production needs and budget.

Environmental Impact and Sustainability

Gravure cylinders typically consume more energy and raw materials during manufacturing compared to flexo sleeves, leading to higher carbon footprints and increased waste generation. Flexo sleeves offer greater sustainability by enabling faster changeovers, reducing material waste, and supporting solvent-free or water-based inks that lower environmental impact. Choosing flexo sleeves can enhance Your eco-friendly printing practices by minimizing resource consumption and promoting cleaner production processes.

Choosing the Right Solution for Your Printing Needs

Gravure cylinders offer superior image quality and durability for high-volume printing, making them ideal for long production runs with consistent results. Flexo sleeves provide faster changeovers and cost-effective flexibility, especially suitable for short to medium runs and variable designs. Selecting the right option depends on production volume, budget constraints, and print detail requirements to optimize efficiency and print quality.

gravure cylinder vs flexo sleeve Infographic

libmatt.com

libmatt.com