Plastic substrates offer superior durability and moisture resistance compared to paper substrates, making them ideal for applications requiring long-lasting performance. Your choice depends on whether you prioritize environmental sustainability and biodegradability, which paper substrates typically provide, or resilience and water resistance, which plastic substrates excel at.

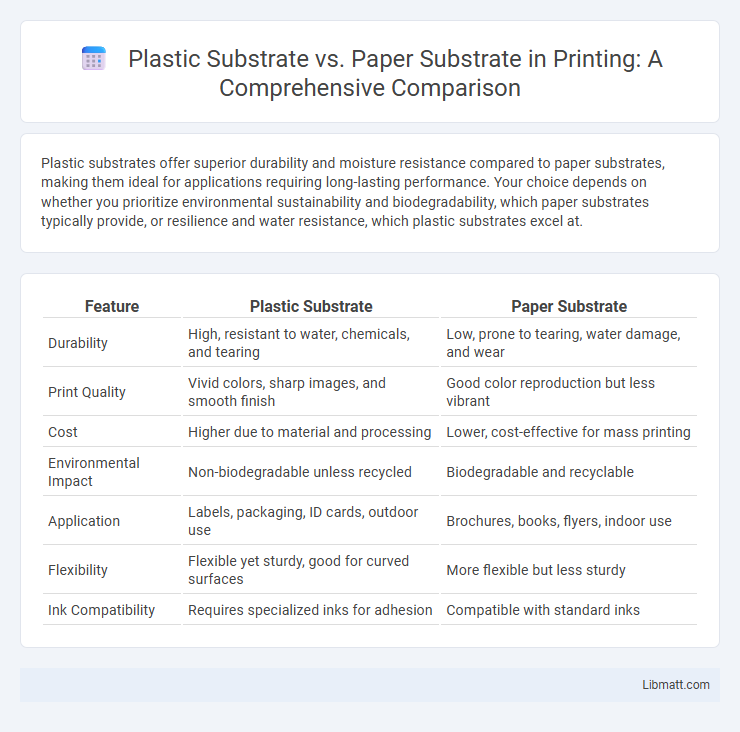

Table of Comparison

| Feature | Plastic Substrate | Paper Substrate |

|---|---|---|

| Durability | High, resistant to water, chemicals, and tearing | Low, prone to tearing, water damage, and wear |

| Print Quality | Vivid colors, sharp images, and smooth finish | Good color reproduction but less vibrant |

| Cost | Higher due to material and processing | Lower, cost-effective for mass printing |

| Environmental Impact | Non-biodegradable unless recycled | Biodegradable and recyclable |

| Application | Labels, packaging, ID cards, outdoor use | Brochures, books, flyers, indoor use |

| Flexibility | Flexible yet sturdy, good for curved surfaces | More flexible but less sturdy |

| Ink Compatibility | Requires specialized inks for adhesion | Compatible with standard inks |

Introduction to Substrate Materials

Plastic substrates offer superior durability, flexibility, and moisture resistance compared to paper substrates, making them ideal for applications requiring longevity and environmental resistance. Paper substrates are biodegradable, cost-effective, and provide excellent print quality, widely used in packaging, labels, and promotional materials. Choosing between plastic and paper substrates depends on factors such as application durability, environmental impact, and budget constraints.

Key Differences Between Plastic and Paper Substrates

Plastic substrates offer superior durability, water resistance, and flexibility compared to paper substrates, making them ideal for applications requiring longevity and moisture exposure. Paper substrates, on the other hand, provide eco-friendly, cost-effective, and biodegradable options favored in short-term, recyclable packaging and printing projects. Understanding these key differences helps optimize your material choice for performance, sustainability, and budget needs.

Environmental Impact: Plastic vs Paper

Plastic substrates contribute significantly to environmental pollution due to their non-biodegradable nature and reliance on fossil fuels, leading to long-term waste accumulation and increased carbon footprint. Paper substrates, derived from renewable resources, typically offer better biodegradability and recyclability but may involve deforestation and higher water usage during production. Understanding these trade-offs helps you make informed decisions to balance sustainability with material performance in your projects.

Durability and Longevity Comparison

Plastic substrates exhibit superior durability and longevity compared to paper substrates due to their resistance to moisture, tearing, and chemical exposure. Paper substrates tend to degrade faster when exposed to environmental factors such as humidity and UV light, leading to reduced lifespan and potential readability issues. High-performance plastic films like polyethylene terephthalate (PET) maintain structural integrity for decades, making them ideal for applications requiring long-term durability.

Printing Quality and Performance

Plastic substrates offer superior printing quality due to their smooth, non-porous surface that enhances ink adhesion and color vibrancy, resulting in sharper images and more consistent prints. Paper substrates, being porous, tend to absorb ink unevenly, which can cause color bleeding and reduced sharpness, especially in high-resolution prints. In terms of performance, plastic substrates provide greater durability, moisture resistance, and longevity, making them ideal for applications requiring long-lasting prints, whereas paper substrates are more susceptible to wear and environmental damage.

Cost Analysis: Plastic vs Paper Substrates

Plastic substrates generally incur higher initial costs compared to paper substrates due to raw material and manufacturing expenses. Paper substrates offer cost-effectiveness with lower material prices and easier recyclability, making them preferred for budget-sensitive applications. However, plastic substrates provide enhanced durability and moisture resistance, potentially reducing long-term costs related to product protection and shelf life.

Recycling and End-of-Life Considerations

Plastic substrates often present challenges in recycling due to their complex polymer structures and potential contamination, resulting in lower recycling rates compared to paper substrates. Paper substrates, being biodegradable and widely accepted in conventional recycling streams, offer more environmentally friendly end-of-life options. Both materials require specific disposal methods to minimize environmental impact, with paper substrates generally favored for circular economy practices.

Applications and Industry Preferences

Plastic substrates dominate in packaging industries for their durability, moisture resistance, and flexibility, making them ideal for food containers, labels, and electronic displays. Paper substrates are preferred in printing, publishing, and eco-conscious packaging sectors due to their biodegradability, recyclability, and compatibility with various inks. Industry preferences hinge on application-specific requirements such as longevity, environmental impact, and print quality.

Regulatory and Compliance Factors

Plastic substrates often meet stringent regulatory requirements for moisture and chemical resistance in packaging, making them suitable for FDA and EU food contact compliance. Paper substrates, while biodegradable and recyclable, must undergo rigorous treatment to achieve similar barrier properties and comply with environmental regulations such as FDA compostability guidelines and forest stewardship certifications. Compliance with sustainability standards like FSC certification and EU's Packaging and Packaging Waste Directive increasingly influences substrate selection in the packaging industry.

Future Trends in Substrate Technology

Plastic substrates offer superior durability and flexibility for emerging electronic and flexible display applications, while paper substrates provide eco-friendly, biodegradable alternatives favored in sustainable packaging. Advances in nanotechnology and conductive inks are driving the development of hybrid substrates that combine the strength of plastic with the recyclability of paper. Your choice of substrate will increasingly depend on balancing performance requirements with environmental impact as future trends prioritize sustainable innovation.

Plastic Substrate vs Paper Substrate Infographic

libmatt.com

libmatt.com