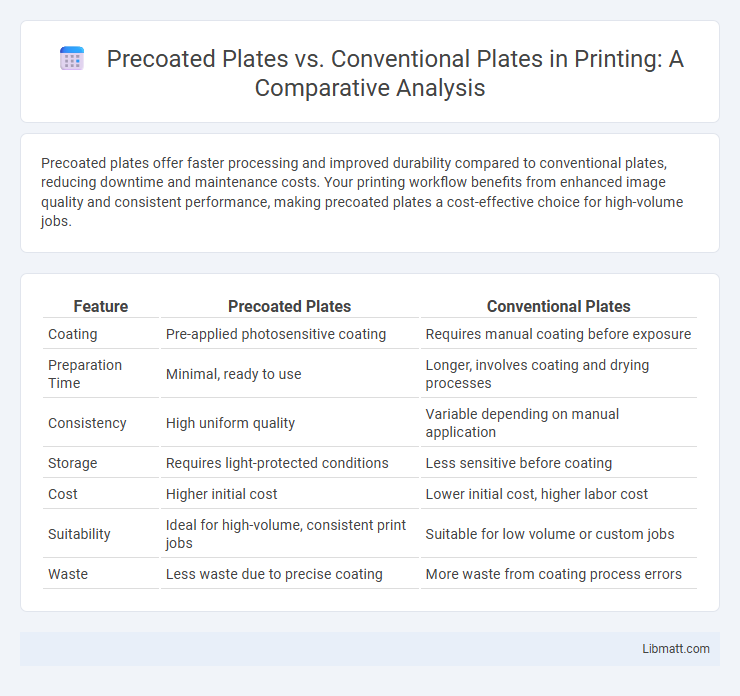

Precoated plates offer faster processing and improved durability compared to conventional plates, reducing downtime and maintenance costs. Your printing workflow benefits from enhanced image quality and consistent performance, making precoated plates a cost-effective choice for high-volume jobs.

Table of Comparison

| Feature | Precoated Plates | Conventional Plates |

|---|---|---|

| Coating | Pre-applied photosensitive coating | Requires manual coating before exposure |

| Preparation Time | Minimal, ready to use | Longer, involves coating and drying processes |

| Consistency | High uniform quality | Variable depending on manual application |

| Storage | Requires light-protected conditions | Less sensitive before coating |

| Cost | Higher initial cost | Lower initial cost, higher labor cost |

| Suitability | Ideal for high-volume, consistent print jobs | Suitable for low volume or custom jobs |

| Waste | Less waste due to precise coating | More waste from coating process errors |

Introduction to Precoated and Conventional Plates

Precoated plates feature a photosensitive layer already applied, enabling faster processing and reduced chemical use compared to conventional plates, which require manual coating before exposure. Conventional plates demand more preparation time and handling, increasing the potential for errors and inconsistencies in plate quality. Your choice between precoated and conventional plates directly influences workflow efficiency and print quality in the prepress process.

Material Composition and Manufacturing Differences

Precoated plates feature a polyester film with a photosensitive coating applied during manufacturing, resulting in consistent quality and easier handling compared to conventional plates made from aluminum or steel with manual coating processes. The manufacturing of precoated plates involves automation that ensures uniform layer thickness and sensitivity, enhancing durability and print quality while reducing exposure to chemicals. Your choice between precoated and conventional plates impacts print efficiency, with precoated plates offering faster setup and reduced waste due to their advanced material composition and manufacturing precision.

Application Processes: Precoated vs Conventional Plates

Precoated plates streamline the application process by eliminating the need for coating and allowing immediate use after exposure, reducing preparation time and errors. Conventional plates require manual coating, drying, and careful handling, which increases processing time and resource consumption. Precoated plates enhance workflow efficiency in offset printing by providing consistent quality and faster turnaround compared to conventional plate preparation methods.

Surface Finish and Coating Quality

Precoated plates offer a consistently superior surface finish due to their factory-applied coating, which ensures uniformity and reduces the risk of defects like scratches or uneven ink absorption. Conventional plates rely on manual coating processes that may result in variable coating thickness and surface irregularities, impacting print quality and durability. You benefit from improved coating quality with precoated plates, delivering sharper images and longer-lasting print performance.

Durability and Corrosion Resistance

Precoated plates exhibit superior durability and corrosion resistance compared to conventional plates due to their protective coating, which enhances longevity and reduces maintenance costs. The precoated layer effectively prevents oxidation and environmental damage, making these plates ideal for harsh industrial and outdoor applications. Conventional plates often require additional treatments or frequent replacements to address corrosion, leading to higher overall lifecycle expenses.

Cost Comparison and Economic Considerations

Precoated plates reduce overall production costs by eliminating the need for chemical processing and drying, saving labor and materials compared to conventional plates. While the initial investment in precoated plates may be higher, Your long-term savings in operational expenses and waste disposal result in a more economical printing solution. Conventional plates incur ongoing expenses for processing chemicals, water, and maintenance, which increase total cost over time.

Environmental Impact and Sustainability

Precoated plates significantly reduce chemical waste since they require fewer solvents and cleaning agents compared to conventional plates, enhancing environmental sustainability. Their longer lifespan and reduced need for processing chemicals minimize resource consumption and waste generation. By choosing precoated plates, You contribute to lower environmental impact and support more sustainable printing practices.

Installation and Maintenance Requirements

Precoated plates offer quicker installation due to their ready-to-use surface, eliminating the need for chemical coating processes required by conventional plates. Maintenance for precoated plates is simpler, as they resist oxidation and surface damage, reducing the frequency of cleaning and recoating compared to conventional plates that demand more intensive care. This efficiency in installation and upkeep translates into lower downtime and operational costs, making precoated plates advantageous for high-volume printing environments.

Industry Use Cases and Suitability

Precoated plates offer enhanced durability and faster setup, making them ideal for high-volume commercial printing in packaging and label production, where efficiency and consistency are critical. Conventional plates remain suitable for short-run applications and custom print jobs in industries prioritizing cost-effectiveness and flexibility, such as small-scale publishing or specialty printing. Your choice depends on print volume and turnaround time, with precoated plates excelling in repetitive, large-scale workflows and conventional plates supporting diverse, lower-volume projects.

Future Trends in Plate Technology

Precoated plates are rapidly gaining traction due to their enhanced durability, reduced chemical usage, and faster press startup times compared to conventional plates. Future trends indicate a shift towards environmentally sustainable materials, improved sensitivity for finer image reproduction, and increased automation in plate processing to boost efficiency. Your choice of plate technology will increasingly rely on innovations that balance cost-effectiveness with high-quality, eco-friendly printing solutions.

Precoated plates vs conventional plates Infographic

libmatt.com

libmatt.com