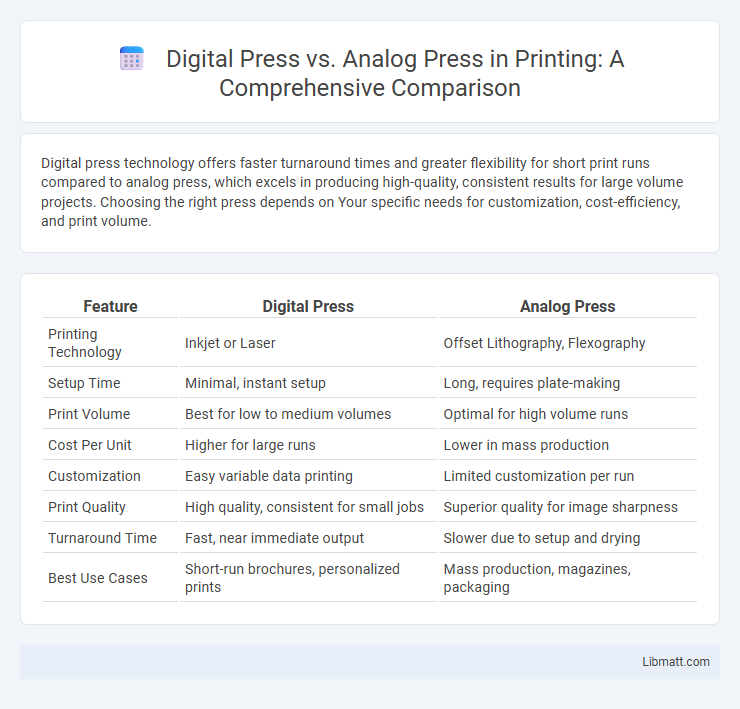

Digital press technology offers faster turnaround times and greater flexibility for short print runs compared to analog press, which excels in producing high-quality, consistent results for large volume projects. Choosing the right press depends on Your specific needs for customization, cost-efficiency, and print volume.

Table of Comparison

| Feature | Digital Press | Analog Press |

|---|---|---|

| Printing Technology | Inkjet or Laser | Offset Lithography, Flexography |

| Setup Time | Minimal, instant setup | Long, requires plate-making |

| Print Volume | Best for low to medium volumes | Optimal for high volume runs |

| Cost Per Unit | Higher for large runs | Lower in mass production |

| Customization | Easy variable data printing | Limited customization per run |

| Print Quality | High quality, consistent for small jobs | Superior quality for image sharpness |

| Turnaround Time | Fast, near immediate output | Slower due to setup and drying |

| Best Use Cases | Short-run brochures, personalized prints | Mass production, magazines, packaging |

Introduction to Digital and Analog Press

Digital press utilizes electronic and computer-based technology to reproduce images and text directly from digital files, offering high-speed, on-demand printing with precise color control and minimal setup time. Analog press, also known as traditional or offset printing, relies on physical plates and mechanical processes to transfer ink onto paper, typically suited for large-volume print runs due to its cost-efficiency and consistent quality. Both methods serve distinct industry needs, with digital presses excelling in flexibility and customization, while analog presses dominate in economies of scale and widespread production.

Key Differences Between Digital and Analog Printing

Digital printing offers faster turnaround times and greater flexibility by directly transferring digital files to the printing substrate, eliminating the need for physical plates used in analog printing. Analog printing, including offset and screen printing, delivers higher consistency and quality for large-volume runs due to established plate-based processes but requires longer setup times and higher initial costs. Digital presses excel in producing variable data prints and short runs efficiently, whereas analog presses are more cost-effective and durable for extensive, uniform print jobs.

Print Quality Comparison

Digital press offers consistently high print quality with sharp details and vibrant colors due to advanced inkjet or laser technology. Analog press, such as offset printing, provides superior color accuracy and smooth gradients, especially for large print runs with complex designs. Your choice depends on the project's resolution needs, color fidelity, and volume requirements.

Speed and Turnaround Times

Digital press technology significantly reduces turnaround times by eliminating the need for plate creation and setup, enabling faster production cycles compared to analog presses. While analog presses deliver consistent high-quality output, their speed is often limited by mechanical setup and longer preparation phases. Digital presses facilitate rapid job changes and on-demand printing, making them ideal for tight deadlines and short-run projects.

Cost Efficiency and Budget Considerations

Digital press technology significantly reduces costs by eliminating the need for plates and enabling on-demand printing, making it ideal for small to medium print runs and variable data jobs. Analog press involves higher setup expenses and is more cost-effective only at large volumes due to economies of scale. Your budget choice depends on print quantity and customization needs, with digital press offering superior cost efficiency for flexible, low-volume projects.

Customization and Flexibility

Digital press technology offers superior customization and flexibility, allowing you to easily modify designs and print small runs without costly setup changes. In contrast, analog press requires extensive preparation and is ideal for large, consistent print runs but lacks the agility to quickly adapt to design changes. This makes digital presses the optimal choice for personalized marketing materials and on-demand printing needs.

Environmental Impact and Sustainability

Digital press technology significantly reduces environmental impact through lower energy consumption and minimal waste generation compared to analog press methods, which rely heavily on chemical-based processes and large volumes of paper. The sustainability of digital printing is enhanced by its ability to print on-demand, thus minimizing overproduction and reducing discarded materials. Furthermore, digital presses support eco-friendly inks and recyclable substrates, promoting a greener printing ecosystem.

Suitable Applications for Each Printing Method

Digital press excels in short-run printing, personalized materials, and on-demand jobs due to its quick setup and ability to produce variable data prints efficiently. Analog press, including offset and flexographic printing, is ideal for large-volume runs, high-resolution images, and consistent color reproduction, making it suitable for newspapers, magazines, and packaging. Each printing method serves distinct needs: digital presses prioritize flexibility and customization, while analog presses focus on cost-efficiency and quality in mass production.

Technological Advancements in Printing

Digital press technology leverages advanced computer-driven processes enabling faster, high-quality prints with minimal setup, while analog press relies on traditional mechanical methods such as plate making. The rise of digital printing has introduced features like variable data printing, allowing personalized content on each piece, which analog presses cannot efficiently handle. Your print projects benefit from digital presses' ability to reduce waste and turnaround time through precise, on-demand production.

Choosing the Right Press for Your Business

Selecting the right press for your business hinges on volume, quality, and budget requirements. Digital presses offer rapid turnaround, variable data capabilities, and cost-efficiency for short runs and customized prints, while analog presses excel in high-volume jobs with consistent color fidelity and lower per-unit costs. Assess your production needs, print complexity, and long-term scalability to determine whether a digital or analog press aligns best with your business goals.

Digital press vs analog press Infographic

libmatt.com

libmatt.com