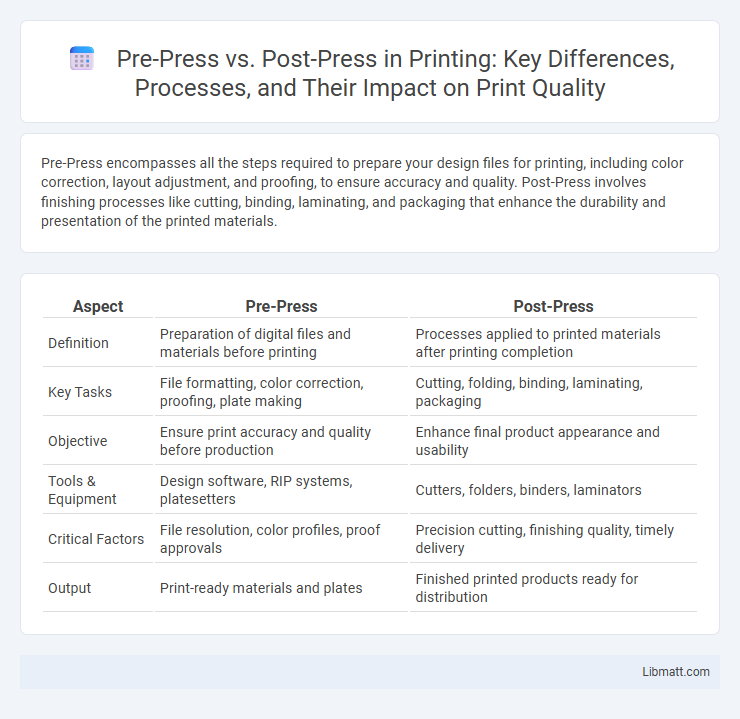

Pre-Press encompasses all the steps required to prepare your design files for printing, including color correction, layout adjustment, and proofing, to ensure accuracy and quality. Post-Press involves finishing processes like cutting, binding, laminating, and packaging that enhance the durability and presentation of the printed materials.

Table of Comparison

| Aspect | Pre-Press | Post-Press |

|---|---|---|

| Definition | Preparation of digital files and materials before printing | Processes applied to printed materials after printing completion |

| Key Tasks | File formatting, color correction, proofing, plate making | Cutting, folding, binding, laminating, packaging |

| Objective | Ensure print accuracy and quality before production | Enhance final product appearance and usability |

| Tools & Equipment | Design software, RIP systems, platesetters | Cutters, folders, binders, laminators |

| Critical Factors | File resolution, color profiles, proof approvals | Precision cutting, finishing quality, timely delivery |

| Output | Print-ready materials and plates | Finished printed products ready for distribution |

Understanding Pre-Press and Post-Press Processes

Pre-Press involves all the preparatory steps before printing, including layout design, color correction, and file formatting to ensure optimal print quality. Post-Press refers to finishing processes such as cutting, folding, binding, and packaging that enhance the final product's appearance and usability. Understanding Pre-Press and Post-Press processes helps you control print accuracy and produce professional-grade materials efficiently.

Key Differences Between Pre-Press and Post-Press

Pre-Press involves all preparatory steps before printing, including design layout, color correction, and plate making, ensuring files are print-ready. Post-Press refers to finishing processes after printing such as cutting, folding, binding, and packaging to enhance the final product's appearance and functionality. Key differences lie in pre-press focusing on accuracy and file preparation, while post-press emphasizes physical finishing and quality enhancement.

Essential Steps Involved in the Pre-Press Stage

The pre-press stage involves critical steps such as file preparation, color correction, and proofing to ensure accurate print output. This phase includes layout adjustment, image retouching, and converting files to the proper format for printing. By mastering these essential pre-press processes, you can significantly reduce errors and streamline the transition into the post-press stage.

Tools and Technologies Used in Pre-Press

Pre-Press involves tools and technologies such as desktop publishing software like Adobe InDesign, Photoshop, and Illustrator, which prepare layouts and graphics for printing. RIP (Raster Image Processors) and proofing devices ensure color accuracy and image quality before production. Your efficient use of these digital tools streamlines the print preparation process, reducing errors and enhancing final output quality.

Importance of Quality Control in Pre-Press

Quality control in pre-press is crucial for ensuring accurate color management, image resolution, and layout alignment before printing, preventing costly errors during production. Strict inspection of digital files and proofing helps maintain consistency, reduce waste, and optimize print output efficiency. Pre-press quality assurance directly impacts the final product's visual integrity and overall customer satisfaction.

Common Challenges in Pre-Press Operations

Common challenges in pre-press operations include color management inconsistencies, file format compatibility issues, and ensuring print-ready artwork accuracy. Misaligned proofs, incorrect bleed settings, and resolution problems often lead to costly delays and rework. Efficient communication between designers and print technicians is crucial to minimize errors and maintain workflow productivity.

Overview of Post-Press Procedures

Post-Press procedures involve finishing steps such as cutting, folding, binding, and laminating that transform printed materials into final products. These processes ensure durability, enhance visual appeal, and tailor outputs to specific uses like brochures, books, or packaging. Understanding Post-Press techniques improves the quality of Your print projects and optimizes production efficiency.

Finishing Techniques in Post-Press

Post-Press finishing techniques enhance the final appearance and durability of printed materials through processes such as laminating, embossing, die-cutting, and binding. These methods refine your product by adding texture, protection, and unique shapes that Pre-Press cannot achieve. Investing in quality Post-Press finishing ensures a professional look and improved tactile experience for your audience.

Impact of Pre-Press and Post-Press on Final Print Quality

Pre-Press processes such as color correction, image editing, and proofing directly influence the accuracy and vibrancy of the final print, ensuring consistent color reproduction and sharp details. Post-Press operations including cutting, laminating, and binding play a crucial role in enhancing the durability, presentation, and tactile quality of the printed material. Both phases are essential for achieving optimal print quality, with pre-press focusing on visual precision and post-press emphasizing finishing and usability.

Choosing the Right Workflow: Pre-Press vs. Post-Press

Choosing the right workflow between pre-press and post-press is crucial for efficient print production and quality output. Pre-press involves all the preparation steps like layout, color correction, and proofing, ensuring your files are print-ready before actual printing. Post-press covers finishing processes such as cutting, binding, and packaging, which enhance the final product's appearance and usability.

Pre-Press vs Post-Press Infographic

libmatt.com

libmatt.com