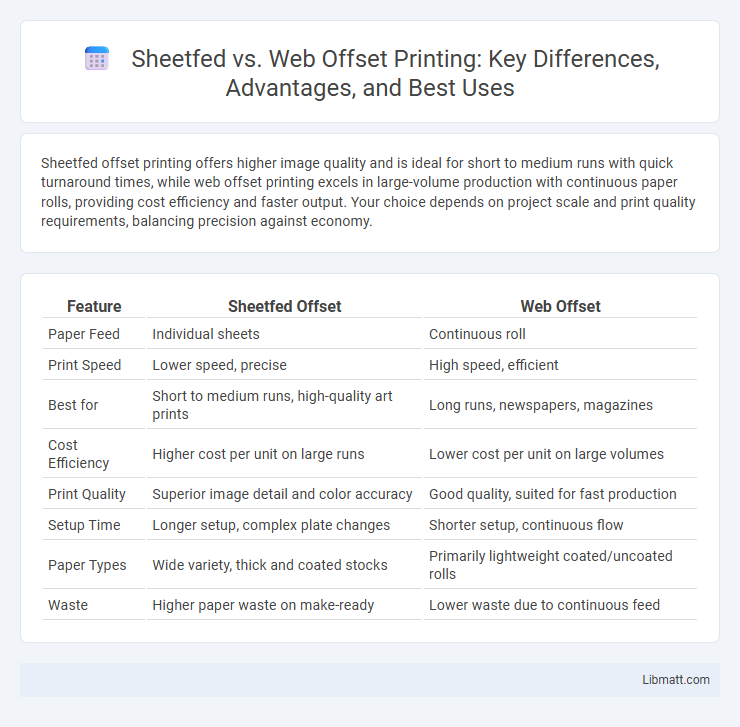

Sheetfed offset printing offers higher image quality and is ideal for short to medium runs with quick turnaround times, while web offset printing excels in large-volume production with continuous paper rolls, providing cost efficiency and faster output. Your choice depends on project scale and print quality requirements, balancing precision against economy.

Table of Comparison

| Feature | Sheetfed Offset | Web Offset |

|---|---|---|

| Paper Feed | Individual sheets | Continuous roll |

| Print Speed | Lower speed, precise | High speed, efficient |

| Best for | Short to medium runs, high-quality art prints | Long runs, newspapers, magazines |

| Cost Efficiency | Higher cost per unit on large runs | Lower cost per unit on large volumes |

| Print Quality | Superior image detail and color accuracy | Good quality, suited for fast production |

| Setup Time | Longer setup, complex plate changes | Shorter setup, continuous flow |

| Paper Types | Wide variety, thick and coated stocks | Primarily lightweight coated/uncoated rolls |

| Waste | Higher paper waste on make-ready | Lower waste due to continuous feed |

Introduction to Sheetfed and Web Offset Printing

Sheetfed printing processes individual sheets of paper, allowing for precise color control and high-quality image reproduction, making it ideal for short to medium print runs and varied paper types. Web offset printing feeds continuous rolls of paper through the press, enabling faster production speeds and cost efficiency for large-volume jobs such as newspapers, magazines, and catalogs. Both methods utilize offset lithography principles but differ in substrate handling and optimal application based on print run length and project requirements.

Key Differences Between Sheetfed and Web Offset

Sheetfed offset printing uses individual sheets of paper fed through the press, offering superior print quality and flexibility for short to medium runs. Web offset printing continuously feeds paper from a large roll, ideal for high-volume jobs with faster production speeds and lower costs per unit. Your choice depends on print volume, quality requirements, and turnaround time, making sheetfed preferable for detailed, smaller jobs and web offset best for mass production like newspapers and magazines.

Advantages of Sheetfed Offset Printing

Sheetfed offset printing offers superior image quality and color accuracy due to precise sheet registration, making it ideal for high-end packaging, brochures, and art prints. It supports a wide variety of paper stocks, including thick or textured materials that web offset cannot handle efficiently. Smaller print runs are more cost-effective and flexible, minimizing waste and setup time compared to continuous web offset processes.

Benefits of Web Offset Printing

Web offset printing offers high-speed production ideal for large volume runs, significantly reducing cost per unit compared to sheetfed presses. It enables continuous printing on rolls of paper, resulting in faster press setup and less downtime, enhancing operational efficiency. This method also supports consistent color quality and precise registration, making it suitable for newspapers, magazines, and mass-market catalogs.

Typical Applications for Sheetfed Printing

Sheetfed printing is commonly used for high-quality applications such as brochures, business cards, magazines, and packaging that require precise color accuracy and sharp detail. It excels in short to medium print runs where customization and quick turnaround times are essential. This method is preferred for materials needing heavier paper stock or specialty finishes that are impractical for web offset presses.

Common Uses for Web Offset Printing

Web offset printing is predominantly used for high-volume projects such as newspapers, magazines, catalogs, and direct mail because it enables rapid production and cost efficiency. Its continuous roll-fed paper system supports long runs and consistent quality, making it ideal for large scale commercial printing. The ability to print on various substrates and integrate post-press finishing processes enhances its versatility for mass distribution materials.

Print Quality Comparison: Sheetfed vs Web Offset

Sheetfed offset printing delivers superior print quality with sharper images and more precise color registration due to individual sheet handling, making it ideal for high-detail projects. Web offset printing, while faster and suitable for large-volume runs, may exhibit slight variations in color consistency and image sharpness because it uses continuous rolls of paper. Your choice depends on the balance between print quality demand and production speed for the specific print job.

Cost Considerations and Production Speed

Sheetfed offset printing typically incurs higher setup costs but offers cost efficiency for short to medium print runs due to less waste and quick job changes. Web offset printing excels in high-volume runs, delivering faster production speeds and lower per-unit costs by continuously feeding rolls of paper, making it ideal for large-scale projects. Your choice depends on balancing setup expenses against production speed and volume requirements to optimize overall printing costs.

Environmental Impact: A Comparative Analysis

Sheetfed offset printing generates less waste and consumes fewer raw materials compared to web offset, making it a more environmentally friendly option for short to medium print runs. Web offset presses, designed for high-volume printing, often use larger amounts of paper and energy, leading to a higher carbon footprint. Your choice between these methods can significantly influence your production's ecological sustainability.

Choosing the Right Printing Method for Your Project

Sheetfed offset printing delivers superior image quality and is ideal for short to medium print runs with customizable finishes, making it perfect for brochures, business cards, and high-end packaging. Web offset printing excels in high-volume jobs such as newspapers, magazines, and catalogs, offering faster production speeds and lower per-unit costs. Selecting the right method depends on project volume, budget, and material requirements to ensure optimal print quality and efficiency.

Sheetfed vs web offset Infographic

libmatt.com

libmatt.com