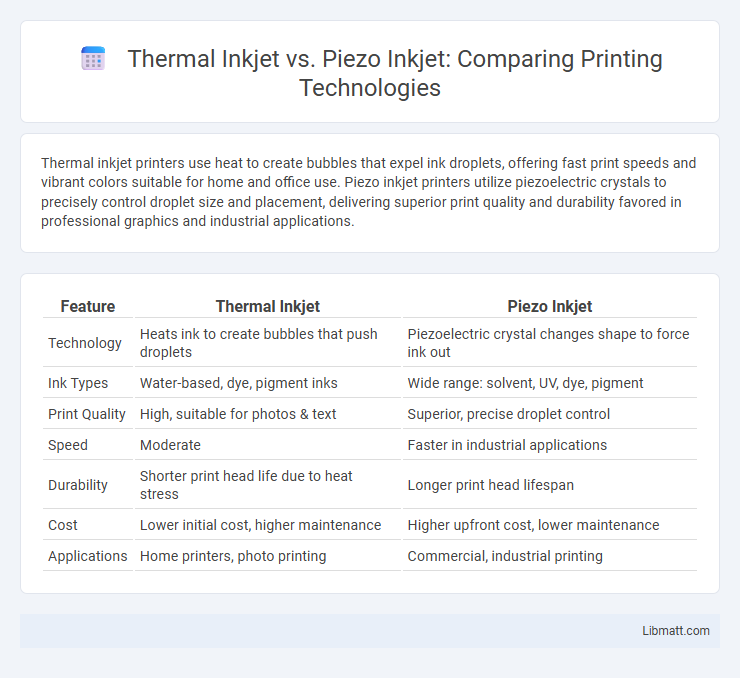

Thermal inkjet printers use heat to create bubbles that expel ink droplets, offering fast print speeds and vibrant colors suitable for home and office use. Piezo inkjet printers utilize piezoelectric crystals to precisely control droplet size and placement, delivering superior print quality and durability favored in professional graphics and industrial applications.

Table of Comparison

| Feature | Thermal Inkjet | Piezo Inkjet |

|---|---|---|

| Technology | Heats ink to create bubbles that push droplets | Piezoelectric crystal changes shape to force ink out |

| Ink Types | Water-based, dye, pigment inks | Wide range: solvent, UV, dye, pigment |

| Print Quality | High, suitable for photos & text | Superior, precise droplet control |

| Speed | Moderate | Faster in industrial applications |

| Durability | Shorter print head life due to heat stress | Longer print head lifespan |

| Cost | Lower initial cost, higher maintenance | Higher upfront cost, lower maintenance |

| Applications | Home printers, photo printing | Commercial, industrial printing |

Introduction to Inkjet Printing Technologies

Thermal inkjet uses heat to create bubbles that force ink droplets onto paper, providing precise and cost-effective printing ideal for home and office use. Piezo inkjet employs piezoelectric crystals to generate pressure pulses that eject ink, offering superior control and durability, often preferred for high-quality and industrial applications. Understanding these core mechanisms helps you choose the best inkjet technology tailored to your specific printing needs.

Overview of Thermal Inkjet Printers

Thermal inkjet printers utilize heat to create a bubble that forces ink droplets onto the paper, resulting in precise and clean printing suitable for high-volume tasks. The technology relies on resistive heating elements that rapidly vaporize the ink, offering advantages in speed and cost-effectiveness. Commonly used in consumer and office printers, thermal inkjet systems excel in producing vibrant colors and detailed images but are limited by the types of inks compatible with heat exposure.

Overview of Piezo Inkjet Printers

Piezo inkjet printers use piezoelectric crystals to precisely control ink droplet ejection, offering superior accuracy and a wider range of compatible ink types compared to thermal inkjet technology. This method avoids heat, preserving ink integrity and supporting high-resolution printing for industrial and professional applications. Your choice of piezo inkjet ensures enhanced durability and versatility for detailed color output on various media.

How Thermal Inkjet Technology Works

Thermal inkjet technology operates by rapidly heating a resistive element to create a vapor bubble that forces ink droplets through a nozzle onto the substrate. This precise thermal actuation enables high-resolution printing with quick droplet ejection, commonly utilized in desktop and office inkjet printers. The ink formulation must withstand rapid heating cycles, typically relying on water-based dyes or pigments for optimal performance and durability.

How Piezo Inkjet Technology Works

Piezo inkjet technology operates using a piezoelectric crystal that changes shape when an electric charge is applied, forcing ink droplets out of the nozzle with precise control. Unlike thermal inkjet, which uses heat to create bubbles that expel ink, piezo inkjet technology offers greater accuracy and a wider range of ink compatibility due to its mechanical ejection method. Your printing quality benefits from this technology's ability to produce consistent droplet sizes and reduce ink waste.

Key Differences: Thermal vs Piezo Inkjet

Thermal inkjet printers use heat to vaporize ink, creating bubbles that force droplets onto the paper, while piezo inkjet printers employ piezoelectric crystals to generate precise pressure pulses, ejecting ink without heat. The thermal method suits fast, cost-effective printing with limited ink types, whereas piezo technology supports a wider variety of inks and delivers higher print quality with greater durability. Understanding these key differences helps you select the ideal inkjet printer for your specific printing needs and materials.

Print Quality Comparison

Thermal inkjet printers use heat to eject ink droplets, producing consistent droplet sizes that result in smooth gradients and sharp text, ideal for high-resolution photo prints. Piezo inkjet technology offers greater control over droplet size and shape by using mechanical pressure, leading to superior color accuracy and fine detail reproduction on various media types. Your choice depends on whether you prioritize vibrant, precise color output (piezo) or cost-effective, high-quality prints in standard applications (thermal).

Ink Compatibility and Media Versatility

Thermal inkjet printers utilize heat to expel ink droplets, making them highly compatible with water-based and dye-based inks, but less suitable for solvent or UV-curable inks typically used in industrial applications. Piezo inkjet technology uses mechanical pressure to eject ink, allowing it to handle a wider range of ink types, including solvent, UV-curable, and pigment-based inks, providing greater media versatility. This capability makes piezo inkjet printers ideal for printing on diverse surfaces such as plastics, textiles, and ceramics, whereas thermal inkjets are generally limited to coated papers and standard office media.

Cost, Maintenance, and Longevity

Thermal inkjet printers generally have lower upfront costs but may incur higher maintenance expenses due to frequent printhead replacements caused by heat-induced wear. Piezo inkjet printers, while typically more expensive initially, offer greater longevity and require less maintenance thanks to their durable piezoelectric printheads that operate without heat. Your choice depends on balancing short-term affordability with long-term reliability and maintenance needs.

Choosing the Right Inkjet Technology for Your Needs

Thermal inkjet technology uses heat to create ink bubbles that eject droplets onto the substrate, making it ideal for affordable, high-speed printing with water-based inks, especially in home and office environments. Piezo inkjet employs piezoelectric crystals to mechanically push ink from the nozzle, offering superior precision and compatibility with a broader range of ink types, including solvent, UV-curable, and dye-based inks, preferred in industrial and professional applications. Selecting the right inkjet technology depends on factors like print quality requirements, ink compatibility, cost considerations, and intended use, ensuring optimal performance and durability for your specific printing needs.

thermal inkjet vs piezo inkjet Infographic

libmatt.com

libmatt.com