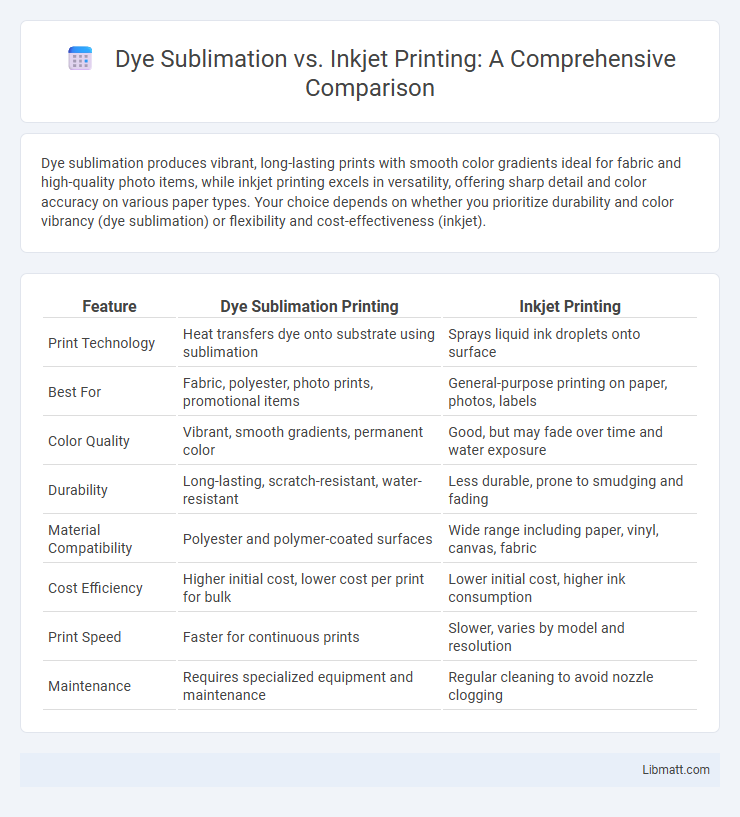

Dye sublimation produces vibrant, long-lasting prints with smooth color gradients ideal for fabric and high-quality photo items, while inkjet printing excels in versatility, offering sharp detail and color accuracy on various paper types. Your choice depends on whether you prioritize durability and color vibrancy (dye sublimation) or flexibility and cost-effectiveness (inkjet).

Table of Comparison

| Feature | Dye Sublimation Printing | Inkjet Printing |

|---|---|---|

| Print Technology | Heat transfers dye onto substrate using sublimation | Sprays liquid ink droplets onto surface |

| Best For | Fabric, polyester, photo prints, promotional items | General-purpose printing on paper, photos, labels |

| Color Quality | Vibrant, smooth gradients, permanent color | Good, but may fade over time and water exposure |

| Durability | Long-lasting, scratch-resistant, water-resistant | Less durable, prone to smudging and fading |

| Material Compatibility | Polyester and polymer-coated surfaces | Wide range including paper, vinyl, canvas, fabric |

| Cost Efficiency | Higher initial cost, lower cost per print for bulk | Lower initial cost, higher ink consumption |

| Print Speed | Faster for continuous prints | Slower, varies by model and resolution |

| Maintenance | Requires specialized equipment and maintenance | Regular cleaning to avoid nozzle clogging |

Introduction to Dye Sublimation and Inkjet Printing

Dye sublimation printing uses heat to transfer dye onto materials like fabric, producing vibrant, long-lasting images ideal for textiles and promotional products. Inkjet printing sprays tiny droplets of ink directly onto a variety of surfaces, offering high versatility and sharp detail for both paper and specialty media. Understanding the strengths of each technology can help you choose the best printing method for your specific project needs.

How Dye Sublimation Printing Works

Dye sublimation printing works by converting solid dye into a gas without passing through a liquid state, which then permeates the printing substrate such as polyester fabrics or specially coated surfaces. This process uses heat and pressure to transfer the dye onto the material, resulting in vibrant, durable, and high-resolution images that are resistant to fading and cracking. Unlike inkjet printing that deposits liquid ink onto the surface, dye sublimation creates a continuous tone image by embedding the dye directly into the fibers, enhancing color accuracy and longevity.

How Inkjet Printing Technology Functions

Inkjet printing technology functions by propelling tiny droplets of ink directly onto paper or other substrates with precise control, creating detailed images through either thermal or piezoelectric mechanisms. This method allows for high-resolution prints with vibrant colors, making it suitable for various applications from photo printing to signage. Your choice between inkjet and dye sublimation depends on the print durability and finish you require.

Print Quality Comparison: Dye Sublimation vs Inkjet

Dye sublimation offers vibrant, continuous-tone images with smooth color gradations, ideal for high-quality photo prints and fabric designs. Inkjet printers provide sharp details and a wider color gamut, excelling in precise graphic reproduction on various paper types. Your choice depends on whether you prioritize seamless color blending or detailed imagery in your printing projects.

Speed and Efficiency: Which Method Wins?

Dye sublimation offers faster print speeds by seamlessly transferring ink through heat, making it highly efficient for large batches and continuous production runs. Inkjet printing, while slower due to its droplet-by-droplet process, provides superior versatility for smaller, detailed jobs with intricate color gradients. Your choice depends on prioritizing speed with dye sublimation or flexibility with inkjet.

Media Compatibility and Versatility

Dye sublimation printing excels with polyester and polymer-coated materials, delivering vibrant, durable images on fabrics, ceramics, and metals. Inkjet printing offers broader media compatibility, including paper, vinyl, canvas, and various textiles, making it ideal for diverse applications. Your choice depends on the specific substrate and desired finish, as dye sublimation specializes in high-quality, permanent prints on synthetic surfaces, while inkjet provides versatility across a wide array of media.

Durability and Longevity of Prints

Dye sublimation prints exhibit superior durability and longevity due to their unique process of infusing dye directly into polyester fibers, resulting in vibrant images that resist fading, cracking, and peeling over time. Inkjet prints, while capable of producing high-quality images, often rely on surface-applied inks that are more susceptible to wear from UV exposure, moisture, and abrasion. For applications requiring long-lasting, fade-resistant prints, dye sublimation is typically preferred over inkjet technology.

Cost Analysis: Dye Sublimation vs Inkjet

Dye sublimation printers generally have higher upfront costs but offer lower long-term expenses due to efficient ink usage and longer-lasting prints. Inkjet printers, while initially more affordable, often incur higher operational costs because of frequent ink replacements and potential maintenance. Evaluating total cost of ownership reveals dye sublimation is more economical for high-volume, high-quality print demands compared to inkjet technology.

Best Applications for Each Printing Method

Dye sublimation excels in printing high-quality images on polyester fabrics, ceramics, and metal, making it ideal for custom apparel, promotional products, and photo panels. Inkjet printing is best suited for versatile applications like printing on various paper types, textiles, and vinyl, providing vibrant colors for fine art, signage, and home decor. Each method maximizes output quality when matched with its intended substrate and design complexity.

Choosing the Right Printing Solution for Your Needs

Dye sublimation printing excels in producing vibrant, long-lasting colors on polyester fabrics and coated surfaces, making it ideal for apparel and promotional products demanding durability and colorfastness. Inkjet printing offers versatile media compatibility, including paper, canvas, and uncoated materials, suitable for detailed photographic prints and short-run customized projects. Selecting the right printing solution depends on fabric type, print lifespan, color quality requirements, and budget constraints.

Dye sublimation vs inkjet Infographic

libmatt.com

libmatt.com