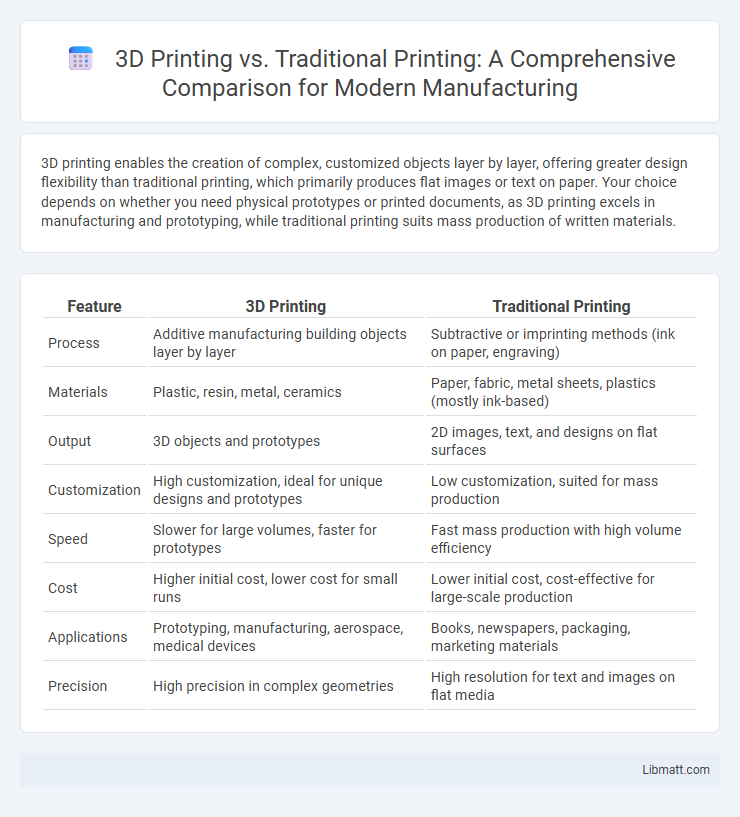

3D printing enables the creation of complex, customized objects layer by layer, offering greater design flexibility than traditional printing, which primarily produces flat images or text on paper. Your choice depends on whether you need physical prototypes or printed documents, as 3D printing excels in manufacturing and prototyping, while traditional printing suits mass production of written materials.

Table of Comparison

| Feature | 3D Printing | Traditional Printing |

|---|---|---|

| Process | Additive manufacturing building objects layer by layer | Subtractive or imprinting methods (ink on paper, engraving) |

| Materials | Plastic, resin, metal, ceramics | Paper, fabric, metal sheets, plastics (mostly ink-based) |

| Output | 3D objects and prototypes | 2D images, text, and designs on flat surfaces |

| Customization | High customization, ideal for unique designs and prototypes | Low customization, suited for mass production |

| Speed | Slower for large volumes, faster for prototypes | Fast mass production with high volume efficiency |

| Cost | Higher initial cost, lower cost for small runs | Lower initial cost, cost-effective for large-scale production |

| Applications | Prototyping, manufacturing, aerospace, medical devices | Books, newspapers, packaging, marketing materials |

| Precision | High precision in complex geometries | High resolution for text and images on flat media |

Introduction to 3D Printing and Traditional Printing

3D printing, also known as additive manufacturing, creates objects layer by layer from digital models, enabling intricate designs and rapid prototyping. Traditional printing involves transferring ink onto paper or other substrates through methods like offset or screen printing, primarily used for mass production of text and images. While 3D printing excels in customization and complex geometries, traditional printing remains cost-effective for high-volume production of two-dimensional materials.

Core Technologies: How Each Method Works

3D printing builds objects layer by layer using digital models, employing technologies such as fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS) to precisely deposit or cure materials. Traditional printing relies on transferring ink or toner onto paper or other substrates through methods like offset printing, screen printing, and flexography, emphasizing high-speed production for text and images. While 3D printing enables complex three-dimensional fabrication with customizable geometries, traditional printing remains optimized for two-dimensional mass reproduction of documents and graphics.

Material Options: Flexibility and Limitations

3D printing offers a wide range of material options including plastics, resins, metals, and ceramics, enabling the creation of complex, customized objects with varied mechanical properties. Traditional printing primarily uses paper, cardstocks, and some fabrics, limiting its flexibility to two-dimensional designs and surface applications. While 3D printing's material versatility supports functional prototypes and end-use parts, traditional printing excels in cost-effective mass production and high-resolution image reproduction on flat media.

Speed and Efficiency Comparison

3D printing significantly reduces production time by enabling rapid prototyping and on-demand manufacturing, often completing complex designs in hours compared to days or weeks with traditional printing. The additive process minimizes material waste, enhancing overall efficiency, while traditional printing methods rely on subtractive techniques that generate more waste. Automation and digital integration in 3D printing streamline workflows, reducing labor costs and accelerating time-to-market across various industries.

Cost Analysis: Upfront vs Operational Expenses

3D printing involves higher upfront costs due to expensive equipment and setup but offers lower operational expenses by minimizing material waste and reducing labor requirements. Traditional printing requires less initial investment in machinery but incurs higher ongoing costs from consumables like ink, paper, and maintenance. Evaluating long-term production volume and customization needs determines overall cost efficiency between these printing methods.

Design Capabilities and Customization

3D printing offers unparalleled design capabilities, allowing intricate and complex geometries that traditional printing methods cannot achieve. Your ability to customize each piece is enhanced by digital modeling, enabling rapid adjustments and unique production runs without additional tooling costs. Traditional printing, while effective for mass production, lacks the flexibility and precision customization inherent in additive manufacturing processes.

Environmental Impact and Sustainability

3D printing significantly reduces material waste by using precise additive manufacturing techniques, unlike traditional printing which often generates excess waste through subtractive processes. The ability to use biodegradable and recyclable materials in 3D printing further enhances its sustainability compared to conventional methods reliant on inks and paper. Energy consumption in 3D printing varies but can be lower overall due to localized production reducing transportation emissions associated with traditional printing supply chains.

Applications Across Industries

3D printing transforms manufacturing by enabling rapid prototyping and customized production in industries like aerospace, automotive, and healthcare, where complex geometries and lightweight structures are essential. Traditional printing methods dominate large-scale, high-speed production of standardized products such as books, newspapers, and packaging materials. Your choice between 3D and traditional printing depends on the required flexibility, scale, and complexity of the application across various industrial sectors.

Quality, Precision, and Finish

3D printing offers superior precision by building objects layer by layer with micron-level accuracy, surpassing the limits of traditional printing methods that rely on fixed templates. While traditional printing can achieve high-quality finishes on flat surfaces through ink or toner application, 3D printing provides complex geometries with consistent quality across varied shapes and textures. The finish of 3D-printed objects benefits from advanced materials and post-processing techniques, enabling smooth surfaces and durable, custom-tailored finishes unmatched by conventional printing technologies.

Future Trends and Innovations

Future trends in 3D printing emphasize advancements in multi-material and bioprinting technologies, enabling complex, customized manufacturing across industries such as healthcare and aerospace. Innovations like faster printing speeds, improved material sustainability, and integration with AI-driven design tools are set to surpass traditional printing capabilities in efficiency and versatility. Your ability to leverage these cutting-edge developments will redefine production processes, reducing waste and fostering on-demand fabrication.

3D printing vs traditional printing Infographic

libmatt.com

libmatt.com