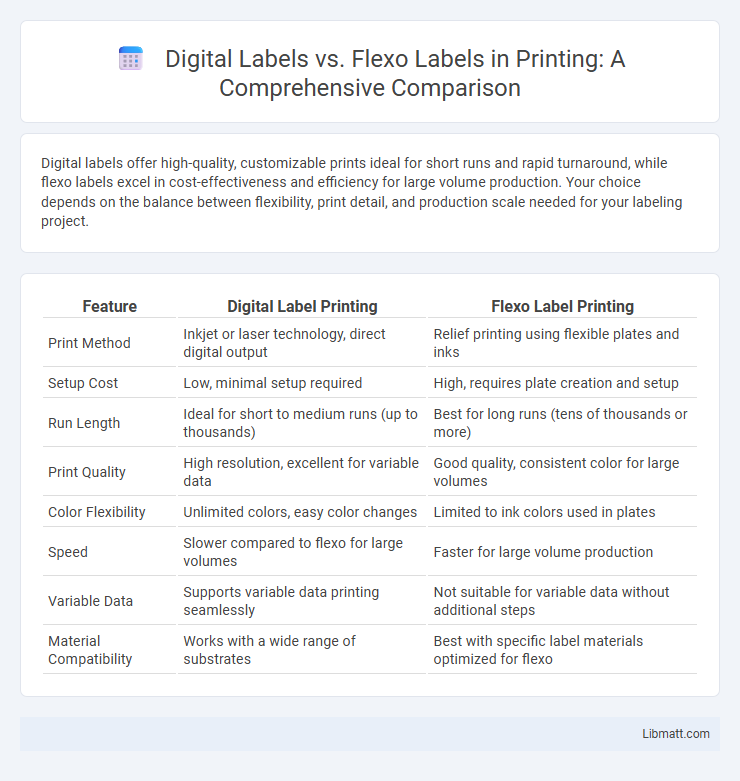

Digital labels offer high-quality, customizable prints ideal for short runs and rapid turnaround, while flexo labels excel in cost-effectiveness and efficiency for large volume production. Your choice depends on the balance between flexibility, print detail, and production scale needed for your labeling project.

Table of Comparison

| Feature | Digital Label Printing | Flexo Label Printing |

|---|---|---|

| Print Method | Inkjet or laser technology, direct digital output | Relief printing using flexible plates and inks |

| Setup Cost | Low, minimal setup required | High, requires plate creation and setup |

| Run Length | Ideal for short to medium runs (up to thousands) | Best for long runs (tens of thousands or more) |

| Print Quality | High resolution, excellent for variable data | Good quality, consistent color for large volumes |

| Color Flexibility | Unlimited colors, easy color changes | Limited to ink colors used in plates |

| Speed | Slower compared to flexo for large volumes | Faster for large volume production |

| Variable Data | Supports variable data printing seamlessly | Not suitable for variable data without additional steps |

| Material Compatibility | Works with a wide range of substrates | Best with specific label materials optimized for flexo |

Introduction to Digital and Flexo Label Printing

Digital label printing employs inkjet or laser technology to produce high-quality, short-run labels with rapid turnaround and customization capabilities, ideal for variable data and limited edition designs. Flexo label printing uses flexible relief plates with fast-drying inks on a continuous roll, making it cost-effective and efficient for large volume production with consistent print quality. Both methods serve distinct market needs, with digital excelling in flexibility and quick production, while flexo dominates in scalability and unit cost efficiency.

Technology Overview: Digital vs Flexo Labels

Digital label technology uses inkjet or laser printing to create high-resolution images directly on the substrate, offering quick turnaround and customization for short runs. Flexo label printing employs flexible relief plates and fast-drying inks for high-volume production with consistent color quality and lower per-unit costs at scale. Your choice depends on whether you prioritize speed and flexibility with digital or cost-efficiency and durability with flexo labeling.

Cost Efficiency and Print Runs

Digital labels offer superior cost efficiency for short print runs due to minimal setup costs and faster turnaround times, making them ideal for small batches and customized designs. Flexo labels become more economical as print runs increase, benefiting from lower per-unit costs through high-speed production and reusable plates. Understanding your print volume and budget will help determine whether digital or flexo labeling provides the best value for your specific needs.

Print Quality and Color Capabilities

Digital labels offer superior print quality with high-resolution images and vibrant color accuracy, ideal for complex designs and short runs. Flexo labels provide consistent color output with excellent durability, particularly suited for large volume runs and simple graphics. Your choice depends on whether you prioritize detailed, customizable color vibrancy or cost-effective, high-speed production.

Turnaround Time and Flexibility

Digital labels offer significantly faster turnaround times compared to flexo labels due to the absence of plate-making processes, enabling same-day or next-day production. Flexo labels require longer setup times and are less flexible for short runs or frequent design changes, making digital printing ideal for highly variable or low-volume projects. The flexibility of digital labels allows for on-demand printing and easy customization, which is challenging and time-consuming with traditional flexo methods.

Customization and Variable Data Printing

Digital labels excel in customization and variable data printing by enabling on-demand, high-resolution prints with unique information on each label, ideal for personalized marketing and limited runs. Flexo labels utilize customized plates for each design, making them cost-effective for large, consistent batches but less flexible for frequent changes or variable data. If your project requires rapid adjustments or unique label data, digital printing offers superior versatility and efficiency.

Environmental Impact and Sustainability

Digital labels generate less waste due to their on-demand printing process, reducing excess materials and energy consumption compared to flexo labels, which require lengthy setup and plates. Flexo printing often uses solvent-based inks that can be harmful to the environment, while digital labels typically use eco-friendly UV or water-based inks with lower volatile organic compounds (VOCs). Your choice of digital labels supports sustainability efforts by minimizing resource use, waste, and harmful emissions throughout the production cycle.

Material and Substrate Compatibility

Digital labels offer superior material and substrate compatibility, supporting a wide range of materials including synthetics, paper, and specialized films without the need for plates. Flexo labels perform best on traditional substrates like coated papers and films but require extensive setup and limiting material flexibility due to plate requirements. Your choice depends on the specific substrate needs and the versatility required for varying label materials.

Use Cases: Best Applications for Each Method

Digital labels excel in short runs, customizable designs, and fast turnaround times, making them ideal for limited editions, variable data printing, and personalized packaging. Flexo labels are best suited for high-volume production, consistent color quality, and cost-effective printing on diverse substrates, perfect for large-scale consumer goods and industrial applications. Your choice depends on whether you prioritize flexibility and speed or efficiency and scalability in labeling needs.

Choosing the Right Label Printing Solution

Digital label printing offers superior flexibility for short runs and customization, providing faster turnaround times and minimal setup costs compared to traditional flexo label printing. Flexo label printing excels in high-volume production with consistent quality and lower cost per unit, making it ideal for large-scale, long-term projects. Selecting the right label printing solution depends on factors such as order volume, design complexity, budget constraints, and sustainability requirements.

Digital label vs flexo label Infographic

libmatt.com

libmatt.com