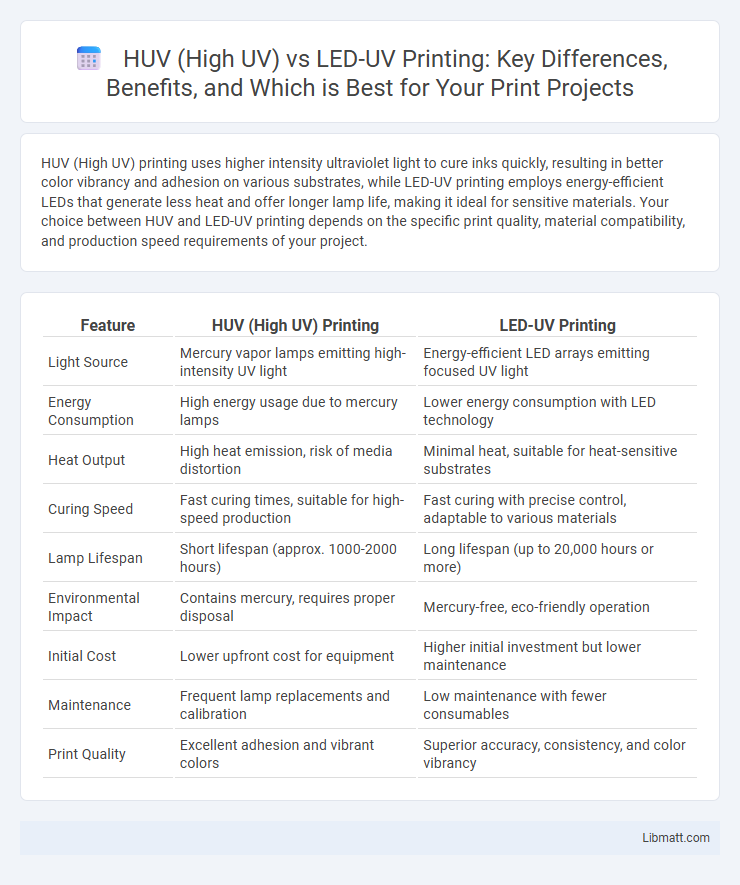

HUV (High UV) printing uses higher intensity ultraviolet light to cure inks quickly, resulting in better color vibrancy and adhesion on various substrates, while LED-UV printing employs energy-efficient LEDs that generate less heat and offer longer lamp life, making it ideal for sensitive materials. Your choice between HUV and LED-UV printing depends on the specific print quality, material compatibility, and production speed requirements of your project.

Table of Comparison

| Feature | HUV (High UV) Printing | LED-UV Printing |

|---|---|---|

| Light Source | Mercury vapor lamps emitting high-intensity UV light | Energy-efficient LED arrays emitting focused UV light |

| Energy Consumption | High energy usage due to mercury lamps | Lower energy consumption with LED technology |

| Heat Output | High heat emission, risk of media distortion | Minimal heat, suitable for heat-sensitive substrates |

| Curing Speed | Fast curing times, suitable for high-speed production | Fast curing with precise control, adaptable to various materials |

| Lamp Lifespan | Short lifespan (approx. 1000-2000 hours) | Long lifespan (up to 20,000 hours or more) |

| Environmental Impact | Contains mercury, requires proper disposal | Mercury-free, eco-friendly operation |

| Initial Cost | Lower upfront cost for equipment | Higher initial investment but lower maintenance |

| Maintenance | Frequent lamp replacements and calibration | Low maintenance with fewer consumables |

| Print Quality | Excellent adhesion and vibrant colors | Superior accuracy, consistency, and color vibrancy |

Introduction to HUV and LED-UV Printing

HUV (High UV) printing employs high-intensity ultraviolet light to cure inks instantly, resulting in vibrant colors and durable prints on various substrates. LED-UV printing uses energy-efficient LED lamps for curing, enabling lower heat emission and longer lamp life while maintaining fast drying times and sharp image quality. Both technologies revolutionize digital printing by offering eco-friendly, solvent-free solutions with enhanced precision and reduced production downtime.

How HUV and LED-UV Printing Technologies Work

HUV printing uses mercury vapor lamps to emit a high-intensity ultraviolet light that cures ink instantly, allowing for faster drying and higher-quality prints on various substrates. LED-UV printing employs light-emitting diodes to generate UV light at specific wavelengths, enabling low-heat curing that reduces energy consumption and extends the lifespan of both the printer and the inks. Both technologies rely on UV light to polymerize ink pigments, but HUV delivers higher power output, while LED-UV offers greater efficiency and environmental benefits.

Key Differences Between HUV and LED-UV Printing

HUV (High UV) printing uses mercury vapor lamps emitting high-intensity UV light, curing inks rapidly with strong adhesion and superior chemical resistance. LED-UV printing employs light-emitting diodes producing cooler, energy-efficient UV light, suitable for heat-sensitive substrates and offering longer lamp lifespan and lower maintenance. Key differences include curing speed, energy consumption, substrate compatibility, and operational costs, with HUV excelling in faster curing and LED-UV favored for eco-friendliness and versatility.

Print Quality: HUV vs LED-UV Output

HUV printing delivers higher print quality with superior ink adhesion and vibrant color accuracy due to its rapid curing process using high-intensity UV lamps, ideal for detailed graphics and glossy finishes. LED-UV printing offers consistent curing with lower heat output, producing sharp images suitable for heat-sensitive substrates but may exhibit slightly less color vibrancy compared to HUV. Both technologies ensure quick drying times, yet HUV excels in achieving deeper curing, enhancing durability and scratch resistance in printed materials.

Speed and Efficiency: Comparing Printing Processes

HUV printing utilizes high-intensity ultraviolet light to cure inks almost instantly, resulting in faster drying times and increased production speed compared to LED-UV printing, which uses lower energy UV LEDs with slightly slower curing rates. The rapid curing of HUV reduces substrate handling time and enhances workflow efficiency, making it ideal for high-volume printing environments. LED-UV printing offers energy savings and longer equipment lifespan but may require slower print speeds to achieve comparable print quality and ink adhesion.

Environmental Impact: Energy Consumption & Emissions

HUV (High UV) printing consumes significantly more energy due to its intense UV lamps, leading to higher electricity usage and increased emissions compared to LED-UV printing. LED-UV technology uses energy-efficient diodes that generate less heat and reduce carbon footprint, making it a more environmentally sustainable choice for your printing needs. Adopting LED-UV printing minimizes harmful emissions and helps conserve energy resources while maintaining high-quality production.

Cost Analysis: Initial Investment and Maintenance

HUV (High UV) printing requires a higher initial investment due to its advanced lamp technology and specialized curing systems, whereas LED-UV printing offers lower startup costs with energy-efficient LED lamps. Maintenance of HUV systems tends to be more expensive because of the frequent replacement of mercury lamps and higher energy consumption, while LED-UV printers boast longer lamp lifespans and reduced upkeep expenses. Your choice between HUV and LED-UV printing hinges on balancing these cost differences with production needs and long-term budget considerations.

Substrate Versatility and Ink Compatibility

HUV (High UV) printing offers superior substrate versatility, allowing high-quality printing on a wide range of materials including plastics, metals, and coated papers due to its intense UV light curing. LED-UV printing, while energy-efficient and producing less heat, is often limited by the wavelength specificity of LED bulbs, which can affect ink adhesion on certain substrates. Understanding the compatibility of your inks with these curing methods ensures optimal print durability and color vibrancy across diverse media.

Ideal Applications for HUV and LED-UV Printing

HUV printing excels in applications requiring rapid drying and superior adhesion on non-porous substrates, such as plastic packaging, labels, and promotional items. LED-UV printing is ideal for eco-friendly production with lower heat emission, suited for delicate materials like heat-sensitive films and flexible packaging. Both technologies enhance print quality and durability, with HUV preferred for high-volume industrial runs and LED-UV favored in energy-efficient, small-batch customization.

Future Trends in UV Printing Technologies

Future trends in UV printing technologies highlight a shift toward High UV (HUV) systems for enhanced curing speed and improved adhesion on diverse substrates, boosting production efficiency. LED-UV printing continues to evolve with energy-efficient lamps that offer longer lifespans, lower heat generation, and reduced environmental impact. Your choice between HUV and LED-UV should align with specific application needs, balancing speed, sustainability, and material compatibility.

HUV (High UV) vs LED-UV Printing Infographic

libmatt.com

libmatt.com