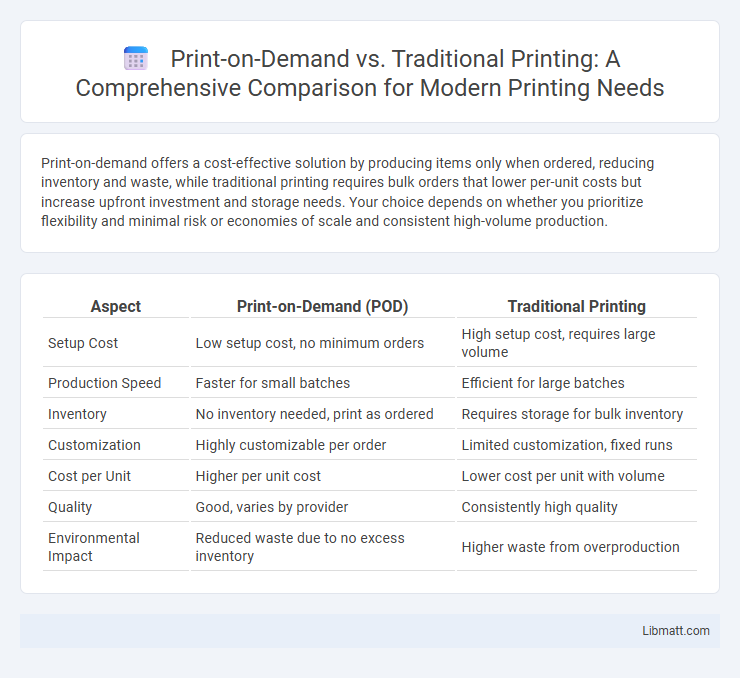

Print-on-demand offers a cost-effective solution by producing items only when ordered, reducing inventory and waste, while traditional printing requires bulk orders that lower per-unit costs but increase upfront investment and storage needs. Your choice depends on whether you prioritize flexibility and minimal risk or economies of scale and consistent high-volume production.

Table of Comparison

| Aspect | Print-on-Demand (POD) | Traditional Printing |

|---|---|---|

| Setup Cost | Low setup cost, no minimum orders | High setup cost, requires large volume |

| Production Speed | Faster for small batches | Efficient for large batches |

| Inventory | No inventory needed, print as ordered | Requires storage for bulk inventory |

| Customization | Highly customizable per order | Limited customization, fixed runs |

| Cost per Unit | Higher per unit cost | Lower cost per unit with volume |

| Quality | Good, varies by provider | Consistently high quality |

| Environmental Impact | Reduced waste due to no excess inventory | Higher waste from overproduction |

Introduction to Print-on-Demand vs Traditional Printing

Print-on-demand (POD) offers a flexible, cost-effective solution by producing items only when ordered, minimizing inventory and upfront costs compared to traditional printing's bulk production model. Traditional printing, utilizing methods like offset printing, excels in high-volume runs with lower per-unit costs but requires significant initial investment and longer lead times. POD leverages digital technology to enable rapid customization and faster turnaround, meeting the demands of modern e-commerce and personalized product markets.

Key Differences Between POD and Traditional Printing

Print-on-demand (POD) offers on-demand production with no minimum order requirements, reducing upfront costs and inventory risks, while traditional printing requires large print runs and higher initial investments. POD uses digital printing technology for fast turnaround and customization, whereas traditional printing relies on offset or screen printing for consistent high-volume output and lower per-unit costs. Your choice depends on order size, budget flexibility, and need for customization or quick delivery.

Cost Comparison: POD vs Traditional Printing

Print-on-demand (POD) significantly reduces upfront costs by eliminating the need for large inventory and bulk printing expenses, making it ideal for small runs or variable designs. Traditional printing requires higher initial investment due to setup fees, plate creation, and minimum order quantities, but it offers lower per-unit costs for large volume production. Cost efficiency in POD scales better with low volume and customization, while traditional printing becomes more economical as order size increases beyond several hundred units.

Production Speed and Turnaround Time

Print-on-demand offers significantly faster production speed and turnaround time compared to traditional printing, as it enables immediate printing of items only when orders are placed, eliminating long setup processes. Traditional printing typically involves lengthy pre-press preparations and large minimum order quantities, which extend delivery timelines. Your ability to quickly respond to market demands improves with print-on-demand, making it ideal for rapid prototyping and limited-run products.

Customization and Flexibility Options

Print-on-demand offers unparalleled customization and flexibility, allowing customers to create unique designs on various products with no minimum order requirements. Traditional printing methods typically require large print runs and setup times, limiting the ability to quickly modify or personalize items. This makes print-on-demand especially advantageous for small businesses and individuals seeking tailored, on-demand production.

Inventory Management and Storage Needs

Print-on-demand minimizes inventory management challenges by producing items only after orders are placed, eliminating the need for extensive storage space. Traditional printing requires maintaining large stockpiles of printed materials, increasing storage costs and risks of unsold inventory. Efficient inventory turnover and reduced overhead make print-on-demand an advantageous option for businesses with limited storage capacity.

Environmental Impact: Sustainability Considerations

Print-on-demand significantly reduces waste by producing items only as needed, minimizing excess inventory and paper use compared to traditional printing. Traditional printing often involves large print runs, leading to surplus materials that contribute to landfill waste and increased carbon emissions from storage and distribution. The sustainability advantage of print-on-demand aligns with eco-friendly practices by lowering resource consumption and enabling localized production, thus reducing transportation-related environmental impact.

Quality and Print Consistency

Print-on-demand offers high-quality, digitally printed products with consistent color accuracy and sharp details across small batches, ideal for customized or limited editions. Traditional printing methods like offset provide superior print quality for large volumes, ensuring uniformity and vibrant colors due to expert calibration and specialized inks. When considering your project, choose print-on-demand for flexibility and quick turnaround, while traditional printing guarantees exceptional consistency for mass production.

Scalability and Market Reach

Print-on-demand offers unparalleled scalability by enabling you to produce items only as orders are placed, eliminating inventory limitations and reducing upfront costs. Traditional printing requires bulk production, which can restrict market reach due to higher initial investment and storage needs. Leveraging print-on-demand technology expands your ability to reach global audiences quickly and efficiently, adapting flexibly to market demand fluctuations.

Choosing the Right Printing Method for Your Needs

Print-on-demand offers flexibility and cost-efficiency for small batches or customized products, eliminating the need for large upfront investments and inventory storage. Traditional printing excels in producing high volumes with consistent quality and lower per-unit costs, ideal for mass production. Assess your project size, budget, and turnaround time to determine whether print-on-demand or traditional printing best aligns with your specific needs.

print-on-demand vs traditional printing Infographic

libmatt.com

libmatt.com