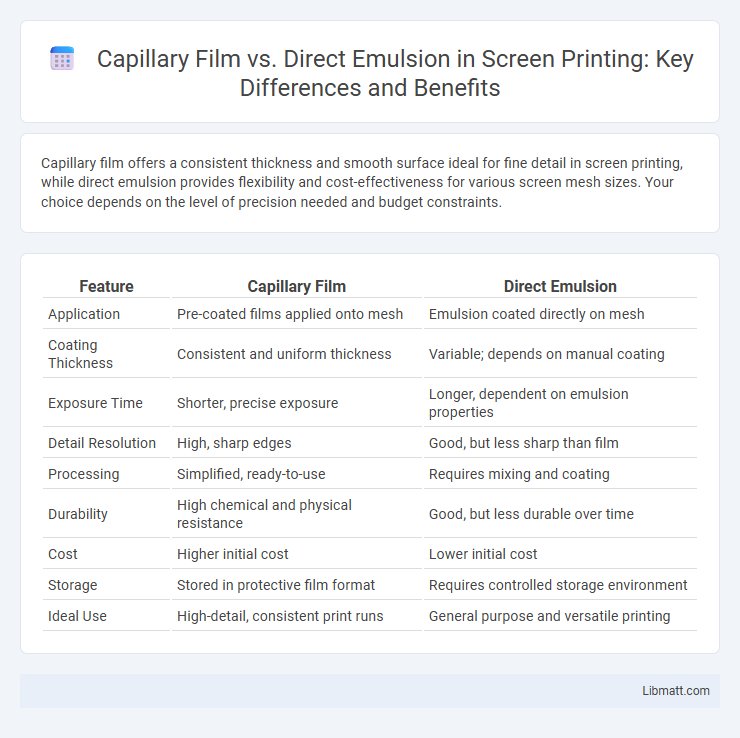

Capillary film offers a consistent thickness and smooth surface ideal for fine detail in screen printing, while direct emulsion provides flexibility and cost-effectiveness for various screen mesh sizes. Your choice depends on the level of precision needed and budget constraints.

Table of Comparison

| Feature | Capillary Film | Direct Emulsion |

|---|---|---|

| Application | Pre-coated films applied onto mesh | Emulsion coated directly on mesh |

| Coating Thickness | Consistent and uniform thickness | Variable; depends on manual coating |

| Exposure Time | Shorter, precise exposure | Longer, dependent on emulsion properties |

| Detail Resolution | High, sharp edges | Good, but less sharp than film |

| Processing | Simplified, ready-to-use | Requires mixing and coating |

| Durability | High chemical and physical resistance | Good, but less durable over time |

| Cost | Higher initial cost | Lower initial cost |

| Storage | Stored in protective film format | Requires controlled storage environment |

| Ideal Use | High-detail, consistent print runs | General purpose and versatile printing |

Understanding Screen Printing: Capillary Film vs Direct Emulsion

Capillary film offers a pre-coated, uniform emulsion layer that ensures consistent stencil thickness and faster setup times compared to the traditional direct emulsion method, where the emulsion is manually applied and dried on the screen. Your choice impacts print quality, durability, and production efficiency, with capillary film providing sharper details and better edge definition ideal for high-volume runs. Direct emulsion remains cost-effective for small batches and custom screen preparation but requires careful coating and drying to avoid inconsistencies.

What Is Capillary Film?

Capillary film is a photosensitive polyester film used in screen printing to create precise stencil patterns through a controlled thickness layer, typically ranging from 10 to 50 microns. Unlike direct emulsion, which involves coating and drying a liquid emulsion directly on the mesh, capillary film allows for consistent thickness and easier handling, resulting in sharper image reproduction and faster preparation times. This film is ideal for high-detail prints and is widely used in industrial and commercial screen printing applications.

Defining Direct Emulsion in Screen Printing

Direct Emulsion in screen printing is a light-sensitive coating applied directly onto the screen mesh, creating a stencil by hardening when exposed to UV light while unexposed areas wash away. This method offers precise detail reproduction and excellent durability, making it ideal for complex, high-resolution designs. You benefit from enhanced print sharpness and cleaner edges compared to capillary film, which uses a pre-coated film adhered to the mesh.

Application Processes Compared

Capillary film offers precise control over image sharpness and is ideal for screen printing processes requiring fine detail, especially in textile and electronics applications. Direct emulsion provides greater flexibility and faster turnaround for lower-volume or larger-format prints but may result in slightly less consistent edge definition. Your choice depends on the balance between production speed and print quality for specific application needs.

Image Resolution and Detail: Which Method Wins?

Capillary film offers superior image resolution and finer detail reproduction compared to direct emulsion due to its consistent thickness and uniform surface texture that enables sharper edges and intricate patterns. The precise control over film thickness in capillary films reduces dot gain and enhances line clarity, making it ideal for high-definition printing applications. Direct emulsion, while versatile, often results in less uniform coverage and slightly lower resolution because of variations in coating thickness and emulsion consistency.

Durability and Print Longevity

Capillary film offers superior durability and print longevity compared to direct emulsion due to its consistent thickness and resistance to chemical degradation. The dense polyester backing of capillary films enhances durability by preventing wear during repeated print runs and washouts. Your prints will benefit from sharper image retention and extended lifespan when using capillary film, especially in high-volume or detailed screen printing applications.

Cost Analysis: Capillary Film vs Direct Emulsion

Capillary film generally incurs higher upfront material costs compared to direct emulsion due to its manufactured polyester base and controlled thickness properties. Direct emulsion offers cost savings in chemical consumption and waste reduction, as it is coated directly onto the screen mesh, minimizing material use. However, capillary film's precision and repeatability can reduce rework and improve overall production efficiency, potentially offsetting initial expenses in large-scale or high-detail applications.

Workflow Speed and Efficiency

Capillary film offers faster workflow speed compared to direct emulsion due to its pre-coated, uniform thickness that minimizes drying and exposure times. The consistent quality of capillary films ensures quicker handling and reduces the risk of defects, leading to higher operational efficiency. Direct emulsion requires longer preparation and drying phases, which can slow down production and increase labor resources.

Best Use Cases for Each Technique

Capillary film is ideal for high-precision, fine-line stencil printing in electronics and graphic arts due to its uniform thickness and excellent resolution. Direct emulsion excels in large-area textile printing and screen printing where flexibility and quick turnaround are needed, offering cost-effectiveness and ease of use. Choosing between capillary film and direct emulsion depends on the balance between detailed accuracy requirements and production volume demands.

Choosing the Right Method for Your Print Project

Capillary film offers consistent thickness and easy handling, making it ideal for high-detail and fine-line screen printing projects, while direct emulsion provides flexibility and cost-effectiveness for short runs or DIY applications. Your selection depends on print complexity, budget, and production volume, as capillary films ensure cleaner edges and faster setup times, whereas direct emulsion allows for customized coating thickness with greater control. Evaluate the durability requirements and print detail of your project to choose the most efficient and reliable stencil-making method.

Capillary film vs direct emulsion Infographic

libmatt.com

libmatt.com