Slip sheets are thin, flat sheets used to separate and stabilize loads, improving pallet efficiency and reducing transport costs, while interleaving involves placing layers of material like paper or plastic sheets between products to prevent damage and enhance stacking stability. Your choice between slip sheet vs interleaving depends on factors such as load type, handling equipment, and protection requirements during storage or shipment.

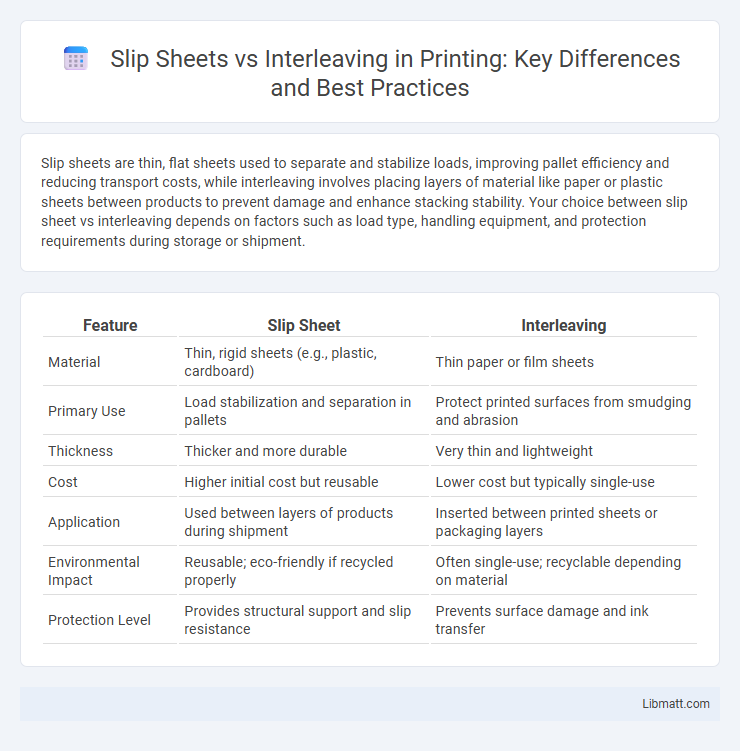

Table of Comparison

| Feature | Slip Sheet | Interleaving |

|---|---|---|

| Material | Thin, rigid sheets (e.g., plastic, cardboard) | Thin paper or film sheets |

| Primary Use | Load stabilization and separation in pallets | Protect printed surfaces from smudging and abrasion |

| Thickness | Thicker and more durable | Very thin and lightweight |

| Cost | Higher initial cost but reusable | Lower cost but typically single-use |

| Application | Used between layers of products during shipment | Inserted between printed sheets or packaging layers |

| Environmental Impact | Reusable; eco-friendly if recycled properly | Often single-use; recyclable depending on material |

| Protection Level | Provides structural support and slip resistance | Prevents surface damage and ink transfer |

Introduction to Slip Sheets and Interleaving

Slip sheets are thin, flat sheets usually made of plastic or cardboard used to separate layers of products on pallets, enhancing stability and facilitating easier handling with push-pull attachments. Interleaving involves placing sheets of paper, plastic, or other materials between individual items to prevent damage, sticking, or abrasion during packaging and transport. Your choice between slip sheets and interleaving depends on product type, handling equipment, and protection needs to optimize shipping efficiency.

What is a Slip Sheet?

A slip sheet is a thin, durable sheet made from materials like corrugated fiberboard or plastic, used to separate and protect layers of products during storage and transport. Unlike traditional pallets, slip sheets reduce shipping weight and improve loading efficiency by allowing forklifts with specialized attachments to move products directly. Your logistics operations can benefit from slip sheets by decreasing costs and minimizing damage to goods.

Understanding Interleaving in Packaging

Interleaving in packaging involves placing sheets or materials between stacked products to protect surfaces from scratches and enhance stability during transport. Unlike slip sheets, which are designed as friction-reducing platforms to replace pallets, interleaving focuses on product-to-product protection within the same package. Understanding the specific requirements of your goods will help determine if interleaving or slip sheets better suit your packaging needs for optimal safety and efficiency.

Key Differences Between Slip Sheets and Interleaving

Slip sheets are thin, durable sheets made of plastic or fiberboard designed to replace traditional pallets by providing a flat surface for stacking and easier material handling, whereas interleaving involves placing sheets of paper or film between layers of products to prevent damage and contamination. Slip sheets optimize pallet space and reduce shipping costs by allowing for more compact stacking and compatibility with specialized push-pull attachments, while interleaving improves product protection during storage and transportation without altering the palletization method. Understanding these key differences helps you select the appropriate solution based on whether your focus is on load stability and cost-efficiency or enhanced product protection.

Material Types: Slip Sheets vs. Interleaving Materials

Slip sheets are typically made from durable materials such as corrugated fiberboard, plastic, or composite fiber, designed to support heavy loads and facilitate easy pallet handling. Interleaving materials, by contrast, often consist of thinner papers, polyethylene films, or foam sheets that provide cushioning and protection between layers of products to prevent damage during transport. Choosing the right material for your slip sheets or interleaving plays a crucial role in optimizing load stability and product safety.

Application Scenarios for Slip Sheets

Slip sheets are widely used in industries such as food processing, pharmaceuticals, and electronics for efficient palletizing and reducing shipping costs. Their application is ideal where automated handling equipment operates, offering increased load stability and protection compared to traditional interleaving methods. Your choice of slip sheets can enhance warehouse space utilization and streamline supply chain logistics by minimizing material thickness.

Common Uses of Interleaving in Industry

Interleaving is commonly used in packaging industries to separate sheets of metal, glass, or plastic films during manufacturing and transportation, preventing surface damage and contamination. In electronics, interleaving helps protect delicate components by inserting thin protective layers between circuit boards or semiconductor wafers. The food industry employs interleaving paper to maintain hygiene and freshness by separating baked goods and frozen products.

Cost Comparison: Slip Sheets vs. Interleaving

Slip sheets generally offer a more cost-effective solution than interleaving due to lower material and handling expenses, as slip sheets are thinner and require less storage space. Interleaving materials, often made from heavier paper or plastic, increase supply costs and can slow down packing processes, impacting overall productivity. Your choice should consider these cost differences alongside specific application needs to optimize budget and efficiency.

Pros and Cons of Slip Sheets and Interleaving

Slip sheets offer cost efficiency and reduced material usage by replacing traditional pallets, enhancing storage density and lowering transportation expenses. However, slip sheets require specialized handling equipment and may cause product damage if not properly aligned. Interleaving provides cushioning and protection between items, reducing abrasion and increasing product stability, though it involves higher material costs and additional labor during packing.

Choosing the Right Solution for Your Packaging Needs

Slip sheets offer a lightweight, cost-effective alternative to traditional pallets, enhancing load stability and reducing shipping expenses, making them ideal for businesses prioritizing space efficiency and eco-friendly packaging. Interleaving, consisting of thin sheets placed between layers of products, provides superior surface protection and prevents product damage during handling, suitable for fragile or high-value items requiring delicate care. Selecting the right solution depends on product type, breakage risk, shipping method, and sustainability goals, ensuring optimal protection and cost savings tailored to specific packaging needs.

Slip sheet vs interleaving Infographic

libmatt.com

libmatt.com