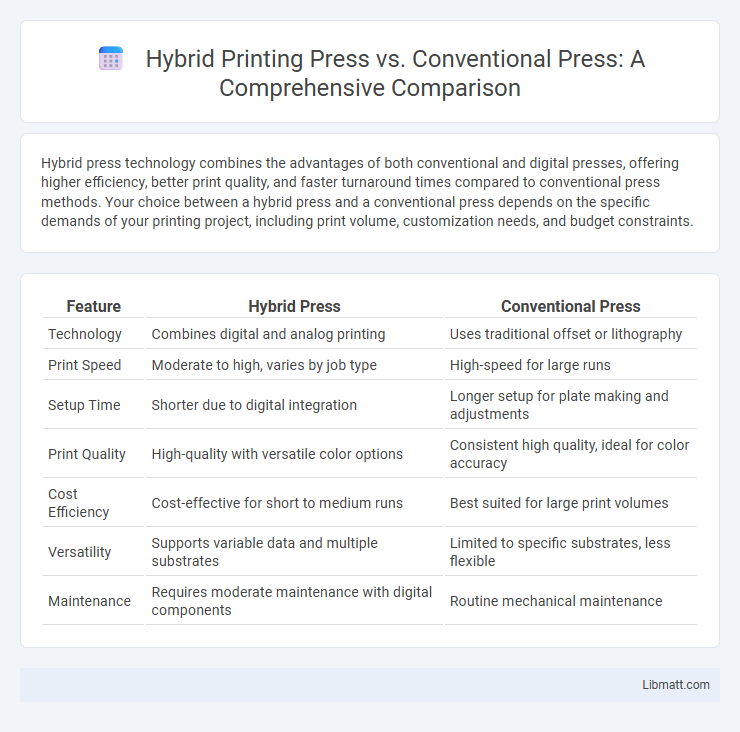

Hybrid press technology combines the advantages of both conventional and digital presses, offering higher efficiency, better print quality, and faster turnaround times compared to conventional press methods. Your choice between a hybrid press and a conventional press depends on the specific demands of your printing project, including print volume, customization needs, and budget constraints.

Table of Comparison

| Feature | Hybrid Press | Conventional Press |

|---|---|---|

| Technology | Combines digital and analog printing | Uses traditional offset or lithography |

| Print Speed | Moderate to high, varies by job type | High-speed for large runs |

| Setup Time | Shorter due to digital integration | Longer setup for plate making and adjustments |

| Print Quality | High-quality with versatile color options | Consistent high quality, ideal for color accuracy |

| Cost Efficiency | Cost-effective for short to medium runs | Best suited for large print volumes |

| Versatility | Supports variable data and multiple substrates | Limited to specific substrates, less flexible |

| Maintenance | Requires moderate maintenance with digital components | Routine mechanical maintenance |

Understanding Hybrid and Conventional Press Technologies

Hybrid press technology integrates mechanical and hydraulic systems, combining high-speed operation with precise pressure control ideal for complex metal forming tasks. Conventional presses primarily rely on mechanical or hydraulic mechanisms separately, offering either speed or force but lacking the combined efficiency found in hybrid models. This fusion in hybrid presses enables improved energy efficiency, enhanced accuracy, and reduced cycle times compared to traditional press systems.

Key Differences Between Hybrid and Conventional Presses

Hybrid presses combine features of both mechanical and hydraulic systems, offering faster cycle times and higher precision compared to conventional presses. Conventional presses primarily rely on a single power source, either mechanical or hydraulic, resulting in slower operation and less adaptability to varying production needs. Hybrid presses excel in energy efficiency and reduced tooling costs, while conventional presses are typically simpler and more cost-effective for low-volume manufacturing.

Advantages of Hybrid Press Printing

Hybrid press printing offers the advantage of combining digital and offset printing techniques, enabling high-quality output with faster turnaround times and cost-efficiency for short to medium runs. It allows seamless handling of variable data printing alongside traditional offset processes, providing greater customization and flexibility. This hybrid approach reduces setup times and waste, making it an eco-friendly and economically viable solution for diverse printing needs.

Benefits of Conventional Press Printing

Conventional press printing offers unmatched color accuracy and consistency, making it ideal for high-volume projects requiring precise reproduction. It supports a wide range of paper types and thicknesses, accommodating diverse printing needs from brochures to packaging. The durability of conventional press plates ensures cost-effectiveness for long print runs, delivering high-quality results with minimal variation.

Cost Comparison: Hybrid Press vs Conventional Press

Hybrid Press technology offers significant cost advantages over Conventional Press methods by reducing material waste and enabling faster setup times, resulting in lower production expenses. Conventional Presses often incur higher operational costs due to increased energy consumption and maintenance requirements. Evaluating your manufacturing needs, Hybrid Presses provide a more cost-effective solution for high-volume production runs.

Print Quality and Consistency Analysis

Hybrid press technology combines the strengths of digital and traditional printing methods, delivering superior print quality with high resolution and vibrant color accuracy. Conventional presses maintain consistent output over large volumes but may lack the fine detail and quick adaptability found in hybrid presses. Your choice depends on the need for precision and consistency in shorter runs versus economies of scale for large print jobs.

Flexibility and Customization in Printing

Hybrid presses offer greater flexibility and customization in printing by combining digital and offset technologies, enabling you to handle short runs and variable data efficiently without compromising print quality. Conventional presses excel in high-volume, consistent output but lack the adaptability to accommodate frequent design changes or personalized printing. This makes hybrid presses ideal for businesses seeking tailored solutions that blend speed, cost-effectiveness, and diverse printing requirements.

Environmental Impact of Hybrid and Conventional Presses

Hybrid presses significantly reduce environmental impact by combining the energy efficiency of electric drives with the force capabilities of mechanical systems, leading to lower power consumption and reduced carbon emissions compared to conventional presses. Conventional presses typically rely on hydraulic or mechanical systems that consume higher amounts of energy and generate more waste heat, contributing to increased greenhouse gas emissions and resource depletion. Your choice of a hybrid press supports sustainable manufacturing practices by minimizing environmental footprint without sacrificing performance.

Applications and Best Use Cases for Each Press Type

Hybrid presses combine hydraulic and mechanical forces, making them ideal for complex forming applications such as automotive parts production and deep drawing processes where precision and high tonnage are required. Conventional presses, including mechanical and hydraulic types, are best suited for simpler tasks like blanking, punching, and straightening, commonly used in metal stamping industries. Your choice depends on the complexity, precision, and volume of the workpieces being manufactured.

Future Trends in Printing Technology

Hybrid presses combine the speed and efficiency of conventional presses with the precision and versatility of digital printing, positioning them at the forefront of future trends in printing technology. Rising demand for customization, shorter print runs, and faster turnaround times drives the adoption of hybrid presses in commercial and packaging industries. Your business can leverage hybrid press technology to stay competitive by integrating advanced automation, AI-driven quality control, and eco-friendly ink solutions that define the next era of sustainable and intelligent printing.

Hybrid Press vs Conventional Press Infographic

libmatt.com

libmatt.com