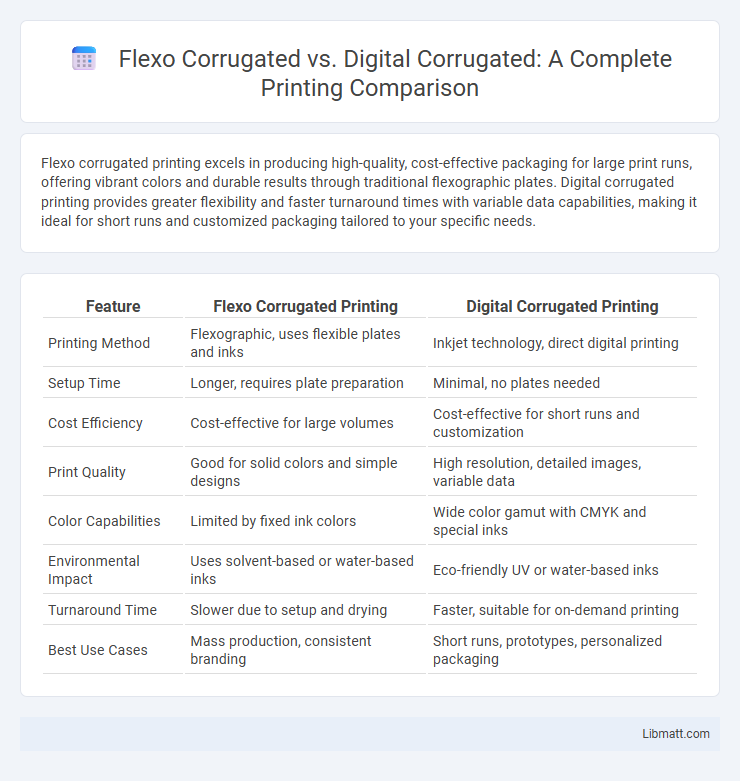

Flexo corrugated printing excels in producing high-quality, cost-effective packaging for large print runs, offering vibrant colors and durable results through traditional flexographic plates. Digital corrugated printing provides greater flexibility and faster turnaround times with variable data capabilities, making it ideal for short runs and customized packaging tailored to your specific needs.

Table of Comparison

| Feature | Flexo Corrugated Printing | Digital Corrugated Printing |

|---|---|---|

| Printing Method | Flexographic, uses flexible plates and inks | Inkjet technology, direct digital printing |

| Setup Time | Longer, requires plate preparation | Minimal, no plates needed |

| Cost Efficiency | Cost-effective for large volumes | Cost-effective for short runs and customization |

| Print Quality | Good for solid colors and simple designs | High resolution, detailed images, variable data |

| Color Capabilities | Limited by fixed ink colors | Wide color gamut with CMYK and special inks |

| Environmental Impact | Uses solvent-based or water-based inks | Eco-friendly UV or water-based inks |

| Turnaround Time | Slower due to setup and drying | Faster, suitable for on-demand printing |

| Best Use Cases | Mass production, consistent branding | Short runs, prototypes, personalized packaging |

Introduction to Corrugated Printing Technologies

Flexo corrugated printing uses flexible relief plates for high-volume runs, delivering consistent color and durability ideal for packaging applications. Digital corrugated printing enables variable data printing with shorter turnaround times and reduced waste, leveraging inkjet or electrophotography technologies. Both methods enhance corrugated board production, balancing cost-efficiency and customization depending on project needs.

What is Flexo Corrugated Printing?

Flexo corrugated printing uses flexible relief plates coated with ink to print high-quality images directly onto corrugated cardboard, offering durability and cost-effectiveness for large runs. Unlike digital corrugated printing, Flexo excels in producing consistent, vibrant colors on various packaging materials, making it ideal for branding and product identification. Your choice depends on volume and design complexity, with Flexo being more efficient for high-volume orders with set designs.

What is Digital Corrugated Printing?

Digital corrugated printing is an advanced printing technology that uses digital files to directly print images and text onto corrugated cardboard, offering faster turnaround times and greater design flexibility compared to traditional flexographic printing. This method eliminates the need for printing plates, allowing for high-resolution, full-color prints with variable data capabilities, making it ideal for customized packaging and short production runs. You benefit from reduced setup costs and the ability to quickly adapt artwork, enhancing your packaging's visual appeal and functionality.

Key Differences Between Flexo and Digital Corrugated

Flexo corrugated printing uses flexible plates and is ideal for high-volume runs due to its cost-efficiency and consistent color reproduction, while digital corrugated printing offers faster turnaround times and greater customization with variable data capabilities. Flexo technology excels in producing vibrant, bold graphics with a longer setup process, whereas digital printing provides high-resolution images without the need for plates, making it suitable for short runs and prototyping. The choice between flexo and digital corrugated depends on factors like order size, print complexity, and budget constraints.

Print Quality Comparison: Flexo vs Digital

Flexo corrugated printing delivers consistent color density with robust durability, ideal for large-volume runs requiring long-lasting impressions. Digital corrugated printing excels in high-resolution details and vibrant color variation, offering superior customization and rapid turnaround without set-up costs. Print quality in digital is sharper for complex graphics, while flexo remains preferred for uniformity and cost-efficiency in bulk production.

Production Speed and Efficiency

Flexo corrugated printing offers faster production speeds due to its streamlined setup and ability to handle long print runs efficiently, making it ideal for high-volume packaging demands. Digital corrugated printing excels in speed for short runs and customized jobs by eliminating plate changes and enabling quick job transitions. Efficiency in flexo comes from its cost-effectiveness in mass production, while digital printing maximizes efficiency through reduced waste and quicker turnaround times for small batches.

Cost Analysis: Flexo Corrugated vs Digital Corrugated

Flexo corrugated printing generally involves higher setup costs due to plate creation but offers lower per-unit expenses for large runs, making it cost-effective for high-volume jobs. Digital corrugated printing has minimal setup costs and excels in short runs or customized orders, but the per-unit cost is higher compared to flexo when scaling up production. Your choice depends on project volume and budget, with flexo suited for bulk printing and digital ideal for smaller, flexible orders.

Sustainability and Environmental Considerations

Flexo corrugated printing uses traditional methods with solvent-based inks and higher energy consumption, resulting in greater environmental impact compared to digital corrugated printing, which employs water-based inks and requires less waste during setup. Digital corrugated technology supports on-demand production, minimizing excess inventory and reducing carbon footprint through shorter print runs and less material waste. Choosing digital corrugated helps your business embrace sustainable practices by lowering emissions, conserving resources, and promoting eco-friendly packaging solutions.

Application Suitability and Market Trends

Flexo corrugated printing excels in high-volume packaging applications demanding consistent, cost-effective results, particularly for brand-aligned packaging and large-run jobs in industries like food and beverages. Digital corrugated printing is ideal for short runs, customization, and rapid turnaround times, gaining traction in e-commerce and retail sectors where personalized packaging and variable data printing drive market growth. Current trends indicate a growing shift towards digital solutions due to advancements in printing technology and sustainability demands, while flexo maintains dominance in traditional large-scale corrugated packaging markets.

Choosing the Right Corrugated Printing Method

Choosing the right corrugated printing method depends on your production volume, budget, and design complexity. Flexo corrugated printing excels in high-volume runs with consistent color quality and cost efficiency, while digital corrugated printing offers greater flexibility for short runs and intricate, variable designs. Your decision should align with whether you prioritize speed and scalability or customization and faster turnaround times.

flexo corrugated vs digital corrugated Infographic

libmatt.com

libmatt.com