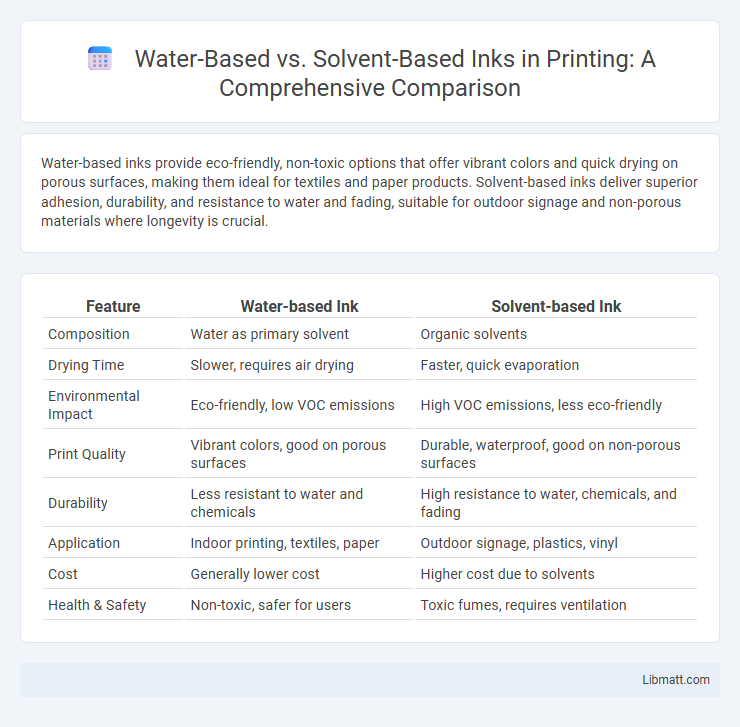

Water-based inks provide eco-friendly, non-toxic options that offer vibrant colors and quick drying on porous surfaces, making them ideal for textiles and paper products. Solvent-based inks deliver superior adhesion, durability, and resistance to water and fading, suitable for outdoor signage and non-porous materials where longevity is crucial.

Table of Comparison

| Feature | Water-based Ink | Solvent-based Ink |

|---|---|---|

| Composition | Water as primary solvent | Organic solvents |

| Drying Time | Slower, requires air drying | Faster, quick evaporation |

| Environmental Impact | Eco-friendly, low VOC emissions | High VOC emissions, less eco-friendly |

| Print Quality | Vibrant colors, good on porous surfaces | Durable, waterproof, good on non-porous surfaces |

| Durability | Less resistant to water and chemicals | High resistance to water, chemicals, and fading |

| Application | Indoor printing, textiles, paper | Outdoor signage, plastics, vinyl |

| Cost | Generally lower cost | Higher cost due to solvents |

| Health & Safety | Non-toxic, safer for users | Toxic fumes, requires ventilation |

Introduction to Water-based and Solvent-based Inks

Water-based inks use water as the primary solvent, making them environmentally friendly and suitable for porous materials like paper and fabric due to their fast drying and low odor characteristics. Solvent-based inks contain organic solvents that dissolve pigments or dyes, offering excellent adhesion and durability on non-porous surfaces such as plastics and metals, but they emit higher volatile organic compounds (VOCs). Both ink types serve distinct industrial printing needs, with water-based inks favored for eco-conscious applications and solvent-based inks preferred for outdoor signage and high-performance graphics.

Composition and Chemical Structure

Water-based inks consist primarily of water as the solvent, combined with pigments or dyes suspended in a water-soluble binder, resulting in a lower VOC content and more environmentally friendly composition. Solvent-based inks use organic solvents such as toluene or xylene as the carrier, facilitating faster drying and improved adhesion on non-porous surfaces due to their hydrophobic chemical structure. The chemical structure of water-based inks typically includes hydrophilic polymers, whereas solvent-based inks incorporate hydrophobic resins that enhance durability and chemical resistance.

Printing Applications and Industry Uses

Water-based inks excel in textile printing, food packaging, and eco-friendly product labeling due to their low toxicity and biodegradability, making them ideal for industries emphasizing sustainability. Solvent-based inks are preferred for outdoor signage, automotive decals, and industrial applications because of their superior adhesion, durability, and resistance to weather and chemicals. The choice between water-based and solvent-based inks depends largely on the substrate type, environmental regulations, and the required longevity of the print job.

Environmental Impact and Sustainability

Water-based inks significantly reduce environmental impact due to their low levels of volatile organic compounds (VOCs) and biodegradability, making them a sustainable choice for eco-conscious printing. In contrast, solvent-based inks contain higher VOC emissions that contribute to air pollution and require specialized disposal methods to mitigate environmental harm. Choosing water-based inks supports sustainability by minimizing hazardous waste and promoting safer production processes in printing industries.

Health and Safety Considerations

Water-based inks emit fewer volatile organic compounds (VOCs), reducing indoor air pollution and making them safer for both workers and consumers. Solvent-based inks contain higher levels of VOCs, which can pose respiratory hazards and require stringent ventilation and protective equipment during handling. Choosing water-based inks can improve Your workplace safety by minimizing exposure to harmful chemicals.

Performance and Print Quality

Water-based inks offer vibrant colors and excellent print quality on porous materials, making them ideal for textiles and paper products. Solvent-based inks provide superior adhesion, durability, and resistance to fading or water, which enhances performance on non-porous surfaces like plastics and metals. Your choice depends on the substrate and desired longevity, with solvent-based inks generally favored for outdoor or heavy-use applications due to their robust performance.

Drying Time and Curing Processes

Water-based inks typically dry faster through evaporation, making them ideal for porous substrates and quick production cycles, while solvent-based inks require longer drying times due to slower solvent evaporation and often need additional curing processes like heat or UV exposure. Your printing choice affects the efficiency of post-print handling, as solvent-based inks offer enhanced durability and adhesion on non-porous materials but incur extended curing times. Optimizing your workflow depends on balancing drying speed with final print quality requirements, especially when handling flexible packaging or outdoor applications.

Substrate Compatibility

Water-based inks excel on porous substrates like paper, cardboard, and fabrics, offering vibrant colors and eco-friendly advantages. Solvent-based inks are ideal for non-porous surfaces such as plastics, vinyl, and metals, providing superior adhesion and durability against environmental factors. Your choice depends on the specific substrate to ensure optimal print quality and longevity.

Cost Comparison and Economic Factors

Water-based inks generally incur lower environmental compliance costs due to reduced VOC emissions, translating to savings in regulatory fees and disposal expenses. Solvent-based inks often require specialized ventilation and handling equipment, increasing operational costs and capital investment. While solvent-based inks may offer superior adhesion and drying speed for certain substrates, their higher raw material and safety-related expenses typically result in a greater overall cost compared to water-based options.

Choosing the Right Ink for Your Needs

Water-based inks offer eco-friendly benefits, quick drying times, and vibrant colors, making them ideal for textiles and food packaging where safety is a priority. Solvent-based inks provide superior durability, water resistance, and adhesion on non-porous surfaces like plastics and metals, perfect for outdoor signage and industrial applications. Your choice depends on the required print quality, substrate compatibility, and environmental considerations.

Water-based vs Solvent-based Inks Infographic

libmatt.com

libmatt.com