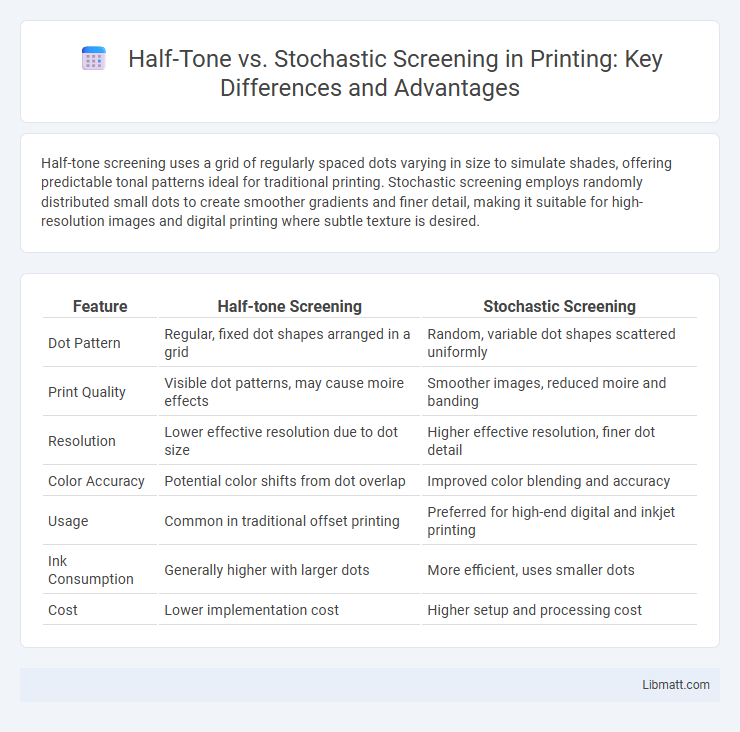

Half-tone screening uses a grid of regularly spaced dots varying in size to simulate shades, offering predictable tonal patterns ideal for traditional printing. Stochastic screening employs randomly distributed small dots to create smoother gradients and finer detail, making it suitable for high-resolution images and digital printing where subtle texture is desired.

Table of Comparison

| Feature | Half-tone Screening | Stochastic Screening |

|---|---|---|

| Dot Pattern | Regular, fixed dot shapes arranged in a grid | Random, variable dot shapes scattered uniformly |

| Print Quality | Visible dot patterns, may cause moire effects | Smoother images, reduced moire and banding |

| Resolution | Lower effective resolution due to dot size | Higher effective resolution, finer dot detail |

| Color Accuracy | Potential color shifts from dot overlap | Improved color blending and accuracy |

| Usage | Common in traditional offset printing | Preferred for high-end digital and inkjet printing |

| Ink Consumption | Generally higher with larger dots | More efficient, uses smaller dots |

| Cost | Lower implementation cost | Higher setup and processing cost |

Introduction to Halftone and Stochastic Screening

Halftone screening uses dots of varying sizes to simulate continuous tones in printed images, creating the illusion of gradients through patterns of spaced dots. Stochastic screening, also known as FM (Frequency Modulated) screening, employs uniformly sized microdots distributed randomly to reduce moire patterns and enhance image detail. Your choice between halftone and stochastic screening impacts print quality, especially in reproducing fine textures and subtle tonal variations.

Historical Development of Screening Techniques

Half-tone screening emerged in the late 19th century with the advent of photographic printing, utilizing regular dot patterns to simulate continuous tones in images. Stochastic screening, developed in the late 20th century, uses randomly distributed microdots to improve image resolution and reduce moire patterns. Your choice between these reflects a balance between traditional print quality and advanced digital precision.

How Halftone Screening Works

Halftone screening works by converting continuous-tone images into a pattern of tiny dots that vary in size or spacing to simulate different shades of gray or color. This technique uses a regular grid of dots, where larger dots create darker areas and smaller dots create lighter ones, enabling printers to reproduce images with a limited color palette. You can use halftone screening to achieve smooth gradients and detailed images in traditional printing processes, optimizing visual perception through fine dot patterns.

Principles of Stochastic (FM) Screening

Stochastic (FM) screening operates by distributing dots of uniform size in random patterns to simulate continuous tones, unlike half-tone screening which uses varying dot sizes arranged in a fixed grid. This method enhances image detail and reduces moire patterns by controlling dot frequency rather than size. FM screening optimizes print quality by leveraging randomized dot placement to achieve smoother gradients and finer textures in printed materials.

Image Quality Comparison: Halftone vs. Stochastic

Halftone screening produces images using dots of varying sizes and fixed patterns, which can lead to visible dot structures and moire patterns, affecting image sharpness and smoothness. Stochastic screening employs randomly distributed micro-dots of uniform size, resulting in finer tonal gradations and reduced pattern artifacts, enhancing perceived image detail and smooth transitions. Overall, stochastic screening offers superior image quality with greater detail fidelity, especially in continuous-tone reproductions compared to traditional halftone methods.

Color Reproduction and Tone Accuracy

Half-tone screening uses a regular grid of dots varying in size to simulate different tones, which can result in visible patterns and less accurate color blending in gradient areas. Stochastic screening employs randomly distributed micro-dots, improving tone accuracy and smoother color reproduction by reducing moire patterns and increasing detail resolution. Your printed images will benefit from stochastic screening's enhanced color fidelity and finer tonal gradations, especially in high-quality color prints.

Printing Applications and Suitability

Half-tone screening is widely used in traditional printing applications such as newspapers and magazines due to its ability to create continuous tone imagery through a pattern of dots with varying sizes. Stochastic screening, also known as FM screening, is more suitable for high-resolution printing tasks, like fine art reproductions and premium packaging, because it uses randomly distributed but uniformly sized dots that enhance detail and reduce moire patterns. Your choice between half-tone and stochastic screening depends on the required print quality, substrate type, and the complexity of the image being reproduced.

Common Challenges and Solutions

Half-tone screening commonly faces challenges like moire patterns and limited tone gradation due to its fixed dot shapes, while stochastic screening struggles with noise-like texture and potential graininess in smooth areas. Solutions for half-tone include using varying dot shapes and angles to minimize moire and improve tonal range, whereas stochastic screening benefits from optimized threshold matrices and noise reduction algorithms to enhance image smoothness and detail. Both methods require careful calibration and software tuning to balance print clarity with visual consistency across different media.

Cost and Production Efficiency

Half-tone screening reduces costs by using a grid of varying-sized dots that are simpler to print on conventional presses, leading to faster production cycles and less waste. Stochastic screening, also known as FM screening, demands higher-quality printing equipment and more precise calibration, which can increase initial expense but often results in better ink coverage and fewer moire patterns, minimizing reprints. Production efficiency improves with half-tone for standard runs due to its compatibility with legacy systems, while stochastic screening excels in high-resolution prints, balancing cost with image quality based on project requirements.

Choosing the Right Screening Method

Choosing the right screening method depends on the print job's detail and tonal range requirements, with half-tone screening offering precise control for images requiring smooth gradients and sharp edges. Stochastic screening uses dispersed dot patterns to reduce moire and improve detail in complex images, making it ideal for high-resolution prints with subtle color transitions. Understanding the final output device and substrate is critical to selecting the screening technique that optimizes print quality and consistency.

half-tone vs stochastic screening Infographic

libmatt.com

libmatt.com