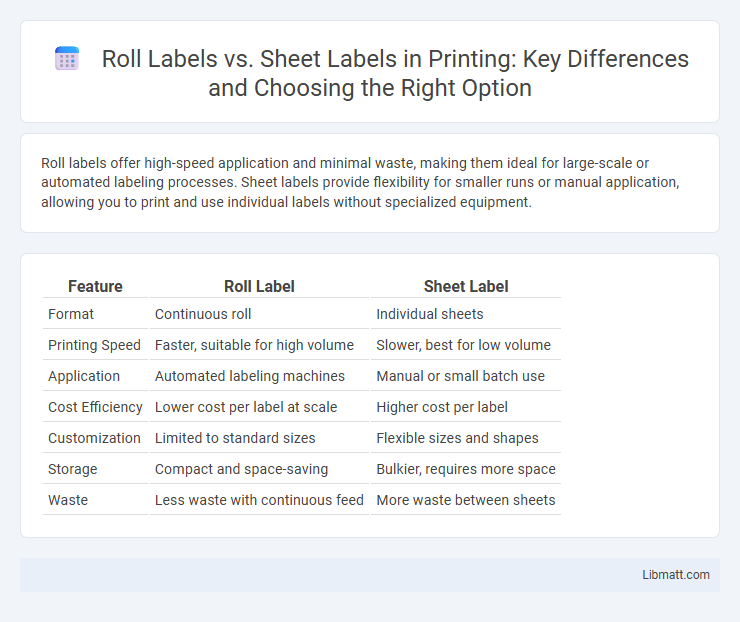

Roll labels offer high-speed application and minimal waste, making them ideal for large-scale or automated labeling processes. Sheet labels provide flexibility for smaller runs or manual application, allowing you to print and use individual labels without specialized equipment.

Table of Comparison

| Feature | Roll Label | Sheet Label |

|---|---|---|

| Format | Continuous roll | Individual sheets |

| Printing Speed | Faster, suitable for high volume | Slower, best for low volume |

| Application | Automated labeling machines | Manual or small batch use |

| Cost Efficiency | Lower cost per label at scale | Higher cost per label |

| Customization | Limited to standard sizes | Flexible sizes and shapes |

| Storage | Compact and space-saving | Bulkier, requires more space |

| Waste | Less waste with continuous feed | More waste between sheets |

Introduction to Roll Labels and Sheet Labels

Roll labels offer continuous labeling solutions, ideal for high-speed automated applications, while sheet labels are pre-cut, perfect for small runs and manual application. Roll labels maximize efficiency in production lines, whereas sheet labels provide versatility and ease of use for varied tasks. Your choice depends on the volume and method of label application required for your project.

Key Differences Between Roll Labels and Sheet Labels

Roll labels provide continuous adhesive material wound on a spool, enabling high-speed automatic application ideal for large-scale labeling processes; sheet labels come pre-cut on individual sheets suitable for manual or low-volume labeling tasks. Roll labels typically support variable data printing with advanced digital presses, while sheet labels excel in color consistency and sharpness on standard office or laser printers. Choosing between roll and sheet labels depends on production volume, application equipment, and printing needs, affecting cost-efficiency and workflow integration.

Advantages of Roll Labels

Roll labels offer significant advantages in high-volume labeling environments due to their continuous feed, which enhances speed and efficiency during application. Their design allows for seamless integration with automatic labeling machines, reducing downtime and increasing productivity compared to sheet labels that require manual handling. Moreover, roll labels minimize waste by optimizing label placement and can be easier to store and transport, making them ideal for industries like food and beverage, logistics, and manufacturing.

Advantages of Sheet Labels

Sheet labels offer precise, easy-to-handle formats suitable for small batch printing and customization, reducing waste and setup time. They work seamlessly with standard office printers, enabling on-demand printing and high-resolution graphics for professional branding. Sheet labels also provide superior alignment control, making them ideal for applications requiring accuracy and quality consistency.

Best Applications for Roll Labels

Roll labels excel in high-speed labeling applications such as product packaging, inventory management, and shipping, where continuous feeding ensures efficiency and reduces downtime. Their flexibility suits curved or irregular surfaces, making them ideal for bottles, containers, and cylindrical products in industries like food and beverage, cosmetics, and pharmaceuticals. Choosing roll labels enhances your labeling process when volume, speed, and adaptability to various shapes are critical.

Ideal Uses for Sheet Labels

Sheet labels are ideal for small-scale labeling projects, office use, and applications requiring easy handling or manual printing with standard laser or inkjet printers. They are perfect for creating address labels, product labeling, and organization tags in environments where precision and flexibility in label design are crucial. Sheet labels offer the convenience of printing multiple labels at once with crisp, sharp images suited for low to medium quantity runs.

Printing and Application Processes Compared

Roll labels offer continuous printing, ideal for high-volume production with automatic application on curved or irregular surfaces, enhancing speed and efficiency. Sheet labels suit low-volume or multi-design runs, requiring manual or semi-automatic printing and application, optimal for flat surfaces and small batches. Both types demand different printers: roll labels use thermal or flexographic printers, while sheet labels are compatible with laser or inkjet printers, influencing cost and quality.

Cost Considerations: Roll Labels vs Sheet Labels

Roll labels generally offer lower cost per unit compared to sheet labels due to more efficient automated application and reduced waste during printing. Sheet labels tend to have higher material and labor costs, especially for small runs or custom designs, as they require manual handling and slower processing. Evaluating your printing volume and application method will help determine whether roll labels or sheet labels provide the most cost-effective solution for your labeling needs.

Choosing the Right Label for Your Business

Selecting the right label between roll labels and sheet labels depends on your business needs, including production volume and application method. Roll labels suit high-speed, automated labeling systems for large batches, offering efficiency and cost-effectiveness, while sheet labels are ideal for smaller runs and manual application, providing flexibility and ease of use. Understanding your packaging process and product type ensures optimal label performance and branding impact.

Conclusion: Which Label Type is Right for You?

Roll labels offer efficiency and speed, ideal for high-volume, automated labeling processes, while sheet labels provide flexibility and precision suitable for smaller batches or manual applications. Your choice depends on the volume, application method, and equipment compatibility needed for your specific labeling project. Consider your production scale and usage environment to determine whether roll or sheet labels best optimize your workflow and cost-effectiveness.

Roll Label vs Sheet Label Infographic

libmatt.com

libmatt.com