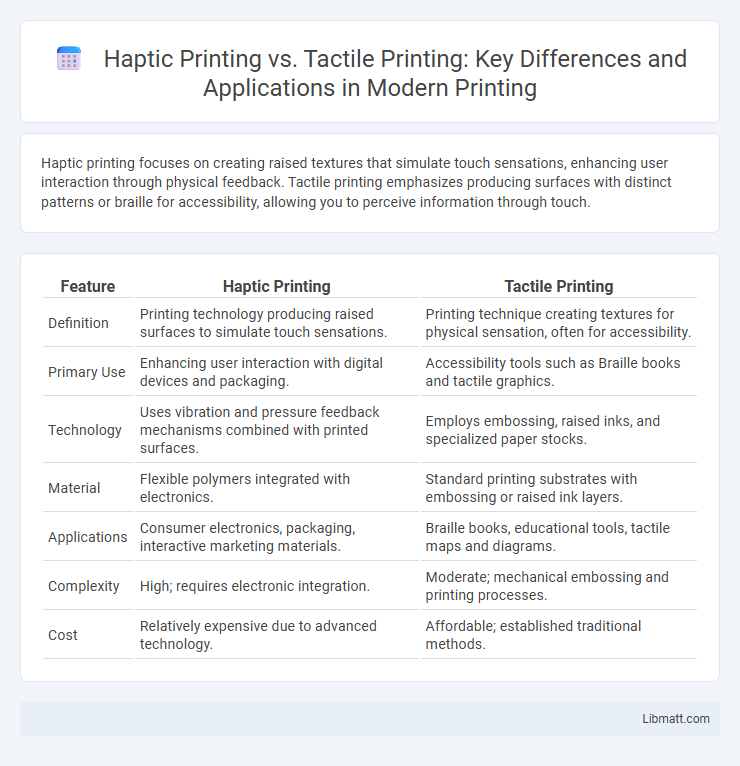

Haptic printing focuses on creating raised textures that simulate touch sensations, enhancing user interaction through physical feedback. Tactile printing emphasizes producing surfaces with distinct patterns or braille for accessibility, allowing you to perceive information through touch.

Table of Comparison

| Feature | Haptic Printing | Tactile Printing |

|---|---|---|

| Definition | Printing technology producing raised surfaces to simulate touch sensations. | Printing technique creating textures for physical sensation, often for accessibility. |

| Primary Use | Enhancing user interaction with digital devices and packaging. | Accessibility tools such as Braille books and tactile graphics. |

| Technology | Uses vibration and pressure feedback mechanisms combined with printed surfaces. | Employs embossing, raised inks, and specialized paper stocks. |

| Material | Flexible polymers integrated with electronics. | Standard printing substrates with embossing or raised ink layers. |

| Applications | Consumer electronics, packaging, interactive marketing materials. | Braille books, educational tools, tactile maps and diagrams. |

| Complexity | High; requires electronic integration. | Moderate; mechanical embossing and printing processes. |

| Cost | Relatively expensive due to advanced technology. | Affordable; established traditional methods. |

Introduction to Haptic Printing and Tactile Printing

Haptic printing involves creating raised or textured surfaces on printed materials that can be felt through touch, utilizing specialized embossing or braille printing techniques to enhance accessibility and sensory interaction. Tactile printing specifically emphasizes producing textures or patterns designed to convey information through touch, often used in materials for visually impaired users to interpret graphics and text via tactile senses. Both haptic and tactile printing technologies advance the functionality of printed materials by integrating physical touch elements that complement visual content.

Defining Haptic Printing: Technology and Applications

Haptic printing utilizes advanced technology to create tactile sensations by integrating microscale actuators or responsive materials within printed surfaces, enabling interactive feedback in digital interfaces and wearable devices. This method leverages piezoelectric elements, electroactive polymers, or ultrasonic actuators to simulate textures, vibrations, or pressure changes, enhancing user experience in virtual reality, medical simulations, and accessibility tools. Applications of haptic printing extend to customizable touch displays, prosthetic skin with sensory feedback, and innovative communication aids for visually impaired users, differentiating it from traditional tactile printing focused primarily on raised or embossed patterns.

Understanding Tactile Printing: Core Concepts and Uses

Tactile printing involves creating raised surfaces on paper or other materials to convey information through touch, commonly used in Braille and educational materials for the visually impaired. This method relies on embossing or debossing techniques to produce textures that enhance accessibility and sensory learning experiences. Unlike haptic printing, which focuses on simulating the sense of touch through electronic feedback, tactile printing provides direct physical textures for tangible interaction.

Key Differences Between Haptic and Tactile Printing

Haptic printing involves creating textures that can be felt through touch using advanced materials and technology to simulate sensations, while tactile printing primarily refers to producing raised surfaces or braille-like features for accessibility. The key difference lies in haptic printing's ability to replicate a variety of tactile sensations beyond simple raised patterns, enabling more immersive and interactive experiences. Tactile printing is generally limited to functional applications for the visually impaired, focusing on readability and recognition rather than sensory complexity.

Materials and Techniques in Haptic Printing

Haptic printing utilizes advanced materials such as conductive inks, silicone elastomers, and shape-memory polymers to create interactive surfaces that respond to touch, enabling dynamic feedback. Techniques include inkjet printing, screen printing, and 3D printing, which allow precise layering and customization of textures directly onto various substrates. Your choice between haptic and tactile printing hinges on the desired level of sensory interaction, with haptic printing offering more complex, responsive material properties.

Materials and Techniques in Tactile Printing

Tactile printing utilizes specialized materials such as thermoplastic embossing powders, swell paper, and UV-curable resins to create raised surfaces that can be felt by touch. Techniques include thermoforming, where heat and pressure shape materials, and embossing, which presses patterns into paper or other substrates to produce three-dimensional textures. Advances in tactile printing also incorporate braille integration and durable materials for enhanced accessibility and longevity in printed materials.

Benefits of Haptic Printing for Accessibility and Design

Haptic printing offers precise texture replication that enhances accessibility by providing visually impaired individuals with distinguishable tactile cues, improving their interaction with printed materials. This advanced technique allows for more detailed and varied surface sensations compared to traditional tactile printing, making designs more engaging and informative. Your projects can benefit from haptic printing's ability to create nuanced sensory experiences that support both functional readability and aesthetic appeal.

Advantages of Tactile Printing for the Visually Impaired

Tactile printing offers enhanced accessibility for the visually impaired by providing raised patterns and textures that can be easily felt and interpreted through touch. Unlike haptic printing, which relies on electronic feedback, tactile printing produces permanent, physical embossed surfaces that do not require any technology to access, ensuring consistent usability. Its durability and simplicity make tactile printing a reliable solution for educational materials and daily-use items, promoting greater independence and inclusivity.

Industry Applications: Comparing Haptic and Tactile Printing

Haptic printing integrates vibration and force feedback to simulate touch sensations, making it ideal for virtual reality, gaming, and advanced medical training devices where dynamic interaction is crucial. Tactile printing, producing raised images or textures, is widely used in Braille materials, educational tools for the visually impaired, and product packaging to convey static information through touch. Your choice between these technologies depends on whether your industry requires interactive touch experiences or durable, easily interpretable tactile content.

Future Trends in Haptic and Tactile Printing Technologies

Future trends in haptic and tactile printing technologies emphasize advancements in material science and sensor integration to create more immersive and interactive experiences. Innovations include the development of programmable textures and dynamic surfaces that respond to touch, enhancing accessibility and user engagement across education, healthcare, and digital media. Your ability to leverage these cutting-edge printing techniques will drive new applications, blending physical and digital touch sensations for more intuitive interactions.

haptic printing vs tactile printing Infographic

libmatt.com

libmatt.com