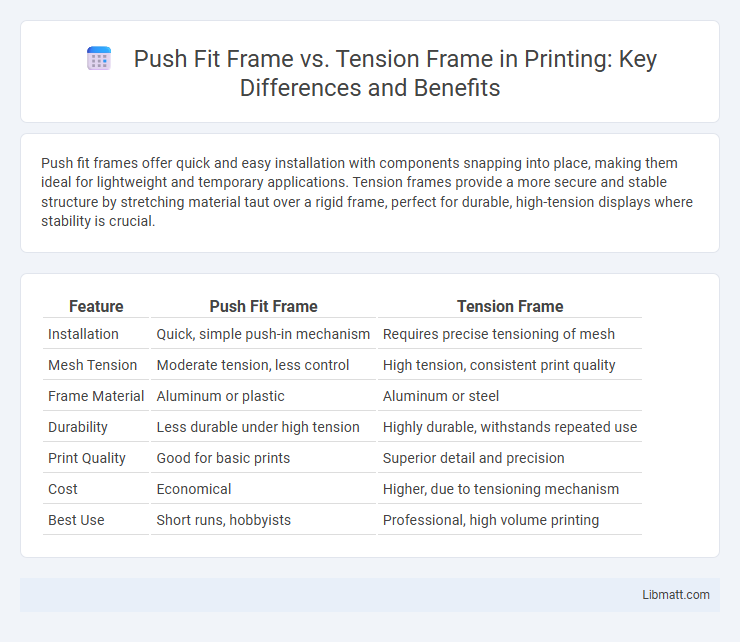

Push fit frames offer quick and easy installation with components snapping into place, making them ideal for lightweight and temporary applications. Tension frames provide a more secure and stable structure by stretching material taut over a rigid frame, perfect for durable, high-tension displays where stability is crucial.

Table of Comparison

| Feature | Push Fit Frame | Tension Frame |

|---|---|---|

| Installation | Quick, simple push-in mechanism | Requires precise tensioning of mesh |

| Mesh Tension | Moderate tension, less control | High tension, consistent print quality |

| Frame Material | Aluminum or plastic | Aluminum or steel |

| Durability | Less durable under high tension | Highly durable, withstands repeated use |

| Print Quality | Good for basic prints | Superior detail and precision |

| Cost | Economical | Higher, due to tensioning mechanism |

| Best Use | Short runs, hobbyists | Professional, high volume printing |

Introduction to Push Fit Frames and Tension Frames

Push fit frames provide a quick and secure installation method by snapping components into place without the need for tools or adhesives, making them ideal for modular construction and lightweight applications. Tension frames rely on tensioned materials, such as fabric or mesh, stretched across a rigid frame to create a smooth, taut surface often used for signage or displays. Your choice between push fit and tension frames depends on the ease of assembly, durability, and the specific application requirements you have.

Key Components of Push Fit Frames

Push fit frames consist of a durable outer frame and flexible inner seals that create a secure, airtight fit without tools, making installation quick and efficient. The key components include a rigid frame, flexible gaskets or seals, and interlocking corners designed to hold the artwork or poster firmly in place. Your choice of a push fit frame ensures simple assembly and easy image rotation, ideal for dynamic displays or frequent updates.

Key Components of Tension Frames

Tension frames consist primarily of a durable outer frame, tensioning straps or cables, and robust corner connectors that create a taut surface for screens or fabric. These components work together to maintain consistent tension, preventing sagging and ensuring a smooth, professional appearance for your display or application. Understanding how each part contributes to the overall stability helps you choose the best tension frame for your needs.

Installation Process: Push Fit vs Tension Frame

The installation process of a push fit frame involves simply pushing the frame into the window or door opening, creating a secure fit through flexible edges that grip the surface firmly without the need for screws or tools. In contrast, a tension frame requires stretching a mesh or screen tightly across the frame, which is then held in place by tension along the edges, often needing a tensioning tool or precise manual adjustment to ensure a snug fit. Push fit frames offer quicker, tool-free installation, while tension frames provide a more customizable and taut screen fit, ideal for varying frame sizes.

Durability and Longevity Compared

Push fit frames and tension frames both offer durability, but push fit frames typically provide greater longevity due to their robust construction from high-quality aluminum or steel. Tension frames rely on fabric tension, which can degrade over time due to environmental factors such as sun exposure and moisture, potentially compromising their lifespan. For applications requiring sustained structural integrity over many years, push fit frames generally outperform tension frames in durability and long-term resilience.

Visual Appeal and Customization Options

Push fit frames offer a sleek, modern look with minimal hardware visible, enhancing the visual appeal through clean lines and seamless integration. Tension frames provide greater customization options, allowing you to adjust fabric tension for a more tailored and dynamic display. Your choice depends on whether you prioritize a minimalist aesthetic or versatile personalization in your framing solution.

Cost Analysis: Push Fit vs Tension Frame

Push fit frames typically offer a more cost-effective solution due to lower material and installation expenses compared to tension frames, which require higher precision and more robust components. Tension frames demand specialized hardware and professional setup, increasing both initial investment and maintenance costs. Businesses seeking budget-friendly display solutions often favor push fit frames for their simplicity and affordability.

Maintenance and Cleaning Differences

Push fit frames offer easier maintenance due to their modular design, allowing individual components to be removed and cleaned without disassembling the entire unit. Tension frames require careful handling during cleaning since the fabric is stretched tightly over the frame, making removal and reinstallation more labor-intensive. Push fit frames typically use materials resistant to dust and moisture buildup, reducing frequent cleaning needs compared to tension frames.

Applications in Various Industries

Push fit frames excel in quick assembly and disassembly, making them ideal for temporary event displays and retail signage where rapid setup and breakdown are crucial. Tension frames offer superior stability and a tight fabric display, commonly used in trade shows, exhibitions, and large-format advertising to create seamless, high-impact visuals. Both frame types are widely utilized in architecture, automotive, and interior design industries to meet specific needs for durability, aesthetics, and ease of use.

Choosing the Right Frame Solution for Your Needs

Push fit frames offer quick, tool-free installation ideal for projects requiring frequent access or adjustments, while tension frames provide a secure, tight fit suited for permanent or heavy-duty applications. Your choice depends on the balance between ease of use and structural stability, with push fit frames prioritizing convenience and tension frames emphasizing durability. Understanding your specific needs will guide you to the frame solution that enhances function and efficiency.

Push fit frame vs tension frame Infographic

libmatt.com

libmatt.com