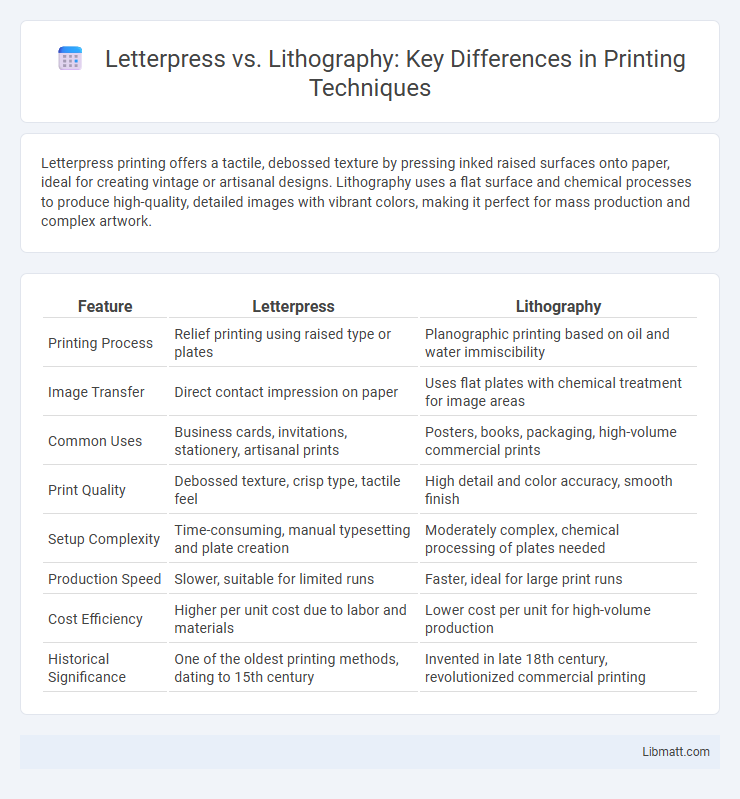

Letterpress printing offers a tactile, debossed texture by pressing inked raised surfaces onto paper, ideal for creating vintage or artisanal designs. Lithography uses a flat surface and chemical processes to produce high-quality, detailed images with vibrant colors, making it perfect for mass production and complex artwork.

Table of Comparison

| Feature | Letterpress | Lithography |

|---|---|---|

| Printing Process | Relief printing using raised type or plates | Planographic printing based on oil and water immiscibility |

| Image Transfer | Direct contact impression on paper | Uses flat plates with chemical treatment for image areas |

| Common Uses | Business cards, invitations, stationery, artisanal prints | Posters, books, packaging, high-volume commercial prints |

| Print Quality | Debossed texture, crisp type, tactile feel | High detail and color accuracy, smooth finish |

| Setup Complexity | Time-consuming, manual typesetting and plate creation | Moderately complex, chemical processing of plates needed |

| Production Speed | Slower, suitable for limited runs | Faster, ideal for large print runs |

| Cost Efficiency | Higher per unit cost due to labor and materials | Lower cost per unit for high-volume production |

| Historical Significance | One of the oldest printing methods, dating to 15th century | Invented in late 18th century, revolutionized commercial printing |

Introduction to Letterpress and Lithography

Letterpress is a traditional printing technique that uses raised surfaces to transfer ink onto paper, creating tactile and crisp impressions ideal for invitations and artistic prints. Lithography relies on the chemical repulsion of oil and water, employing flat plates to produce high-quality images suitable for mass production and detailed graphic work. Understanding these distinct methods allows you to choose the perfect printing style for your project's texture and visual impact.

Brief History of Printing Techniques

Letterpress printing, invented by Johannes Gutenberg in the 15th century, revolutionized mass communication by using movable type to press ink onto paper. Lithography, developed in the late 18th century by Alois Senefelder, introduced a chemical process relying on the immiscibility of oil and water to transfer images from a flat stone or metal plate. Understanding these historic printing techniques helps you appreciate the evolution of print media and the unique characteristics of each method in producing distinct textures and image qualities.

How Letterpress Works

Letterpress printing involves pressing a raised, inked surface directly onto paper, creating rich textures and crisp lines. Your design is carved or molded into a plate, and ink is applied to the raised areas before being pressed onto the substrate. This traditional method offers tactile depth and a vintage feel unmatched by other printing techniques like lithography.

How Lithography Works

Lithography operates on the principle of oil and water repulsion, using a flat stone or metal plate treated to attract ink only on the drawn areas while repelling water on non-image sections. The image is transferred to a rubber blanket and then pressed onto paper, allowing for high-quality, detailed prints with smooth tonal gradations. This chemical process enables efficient mass production of images with consistent color fidelity, making it ideal for commercial printing and fine art reproduction.

Material and Equipment Comparison

Letterpress printing utilizes raised metal or polymer plates pressed onto paper with a heavy press, requiring durable printing presses such as platen or cylinder presses and oil-based inks that absorb into the paper surface. Lithography relies on flat stone or metal plates treated with grease-based inks and water, using sophisticated offset presses and rollers to transfer ink from the plate to a rubber blanket and then onto paper, enabling high-volume and detailed image reproduction. Material-wise, letterpress demands thick, absorbent paper to withstand pressure and create texture, while lithography accommodates various paper weights and finishes due to its non-contact printing method.

Print Quality and Visual Characteristics

Letterpress printing produces crisp, tactile impressions with deep, rich ink coverage and noticeable texture due to the raised type pressing into the paper. Lithography offers smooth gradients and sharp, detailed images with vibrant color reproduction, leveraging the chemical repulsion of oil and water for precise ink transfer. Print quality in letterpress emphasizes tactile depth and handcrafted appeal, while lithography excels in fine detail and consistent color across large print runs.

Cost and Efficiency Analysis

Letterpress involves higher setup costs and longer production times due to manual typesetting and plate creation, making it less efficient for large print runs. Lithography offers lower per-unit costs for high-volume printing through faster, automated processes and digital plate technology. Your choice depends on balancing initial investment against production speed and scale requirements.

Popular Applications of Letterpress

Letterpress printing remains popular for producing wedding invitations, business cards, and luxury packaging due to its tactile, embossed quality and rich texture. This traditional technique offers a distinctive handcrafted feel that lithography, known for high-volume and detailed color reproduction, cannot replicate. You benefit from letterpress when seeking an elegant, artisanal finish that enhances the perceived value of printed materials.

Popular Applications of Lithography

Lithography is popular for producing high-quality art prints, detailed commercial posters, and precise circuit board manufacturing due to its ability to create fine, consistent lines. It is widely used in graphic design for mass media printing, including newspapers and books, because of its efficiency and scalability. The technology's versatility also makes it ideal for colorful packaging and intricate illustrations, maintaining sharpness and color fidelity.

Choosing the Right Printing Method

Choosing the right printing method depends on your project's design complexity, budget, and desired texture. Letterpress offers a tactile, debossed effect ideal for invitations and business cards, while lithography excels in producing vibrant, high-resolution images suitable for mass production. Consider your print run size and visual goals to determine whether the artisan quality of letterpress or the efficiency and color fidelity of lithography best suits your needs.

Letterpress vs Lithography Infographic

libmatt.com

libmatt.com